Information injection-pump assembly

BOSCH

9 460 611 344

9460611344

ZEXEL

104740-2930

1047402930

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-2930 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-2930 |

| 3. | NUMBER PLATE | 146980-6700 |

| 4. | _ | 146672-7520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105140-1070 |

| 8. | Nozzle and Holder | 16600-59Y11 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-1361 |

| 11. | NOZZLE | 105000-2270 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0320 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2220 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6720 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2500 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3220 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-4220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2021 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-0720 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146538-2720 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146561-9720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-2000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 138. | [1] | 146665-5220 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146587-6400 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2900 | COILED SPRING |

| 221. | [1] | 146933-8520 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146934-0520 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146665-4120 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146929-6320 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-4620 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 309. | [3] | 020146-1270 | BLEEDER SCREW |

| 309. | [3] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146684-9220 | POTENTCIOMETER |

| 310/2. | [1] | 146933-9620 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146621-0500 | UNION NUT |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 311. | [2] | 146620-9600 | BLEEDER SCREW |

| 329. | [1] | 146541-4900 | PLAIN WASHER D20&10T0.5 |

| 800S. | [1] | 146009-3920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146684-9110 | POTENTCIOMETER |

| 903. | [1] | 146672-7520 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146980-6700 | NAMEPLATE |

Include in #2:

104740-2930

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 344

9460611344

ZEXEL

104740-2930

1047402930

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

36.2

37

Difference in delivery

mm3/st.

0.2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

33.3

30.8

35.8

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

33.4

30.4

36.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

35.6

37.6

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

36.5

34.5

38.5

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

34.9

32.4

37.4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

12

16

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

10.5

17.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9.5

11.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

8.5

12.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

20.5

14

27

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

15.7

8.7

22.7

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

393

451

Pressure

kgf/cm2

4.3

4

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

383

461

Pressure

kgf/cm2

4.3

3.9

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

588

549

627

Pressure

kgf/cm2

6

5.6

6.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2400

2400

2400

Pressure

kPa

726

677

775

Pressure

kgf/cm2

7.4

6.9

7.9

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.4

3.1

3.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7.4

6.9

7.9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke

mm

9.4

8.9

9.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.78

6.68

6.88

MS dimension

mm

0.8

0.7

0.9

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

42

37

47

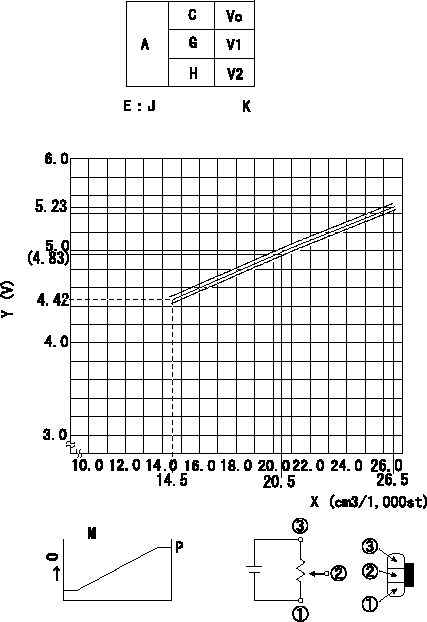

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Adjustment conditions

B:Adjustment value

C:Position of the control lever

N:Pump speed

Q:Injection quantity

Vo:Output voltage

D:Measured injection quantity

E:Conversion formula

F:Adjusting point

G:Idle

H:Full speed

I:Checking point

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

----------

N1=700r/min a=9deg L=5.95mm

----------

V1=2.34+-0.75V V2=9.96++V K=10V J:V+-0.03=0.1065X+2.8519(X<15.2mm3/1,000st) V+-0.03=0.0674X+3.4462(X>=15.2mm3/1,000st)

----------

N1=700r/min a=9deg L=5.95mm

----------

V1=2.34+-0.75V V2=9.96++V K=10V J:V+-0.03=0.1065X+2.8519(X<15.2mm3/1,000st) V+-0.03=0.0674X+3.4462(X>=15.2mm3/1,000st)

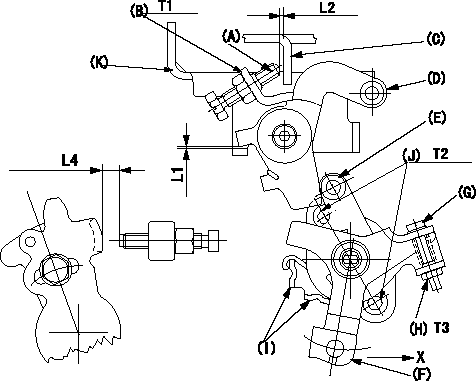

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idle position.

(2)Insert a block gauge (thickness gauge) L1 between the intermediate lever D and the bracket K. Adjust the distance between screw A and the control lever to L2 and fix using the nut.

Adjust screw (A) and fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever F in the direction X until it contacts the stopper I and tighten the socket head bolt J when the timer stroke is L3.

3. Screw (G) adjustment

(1)Adjust using the screw G so that the roller E contacts the intermediate lever D, then fix using the nut H.

(2)Pull the CSD lever F in the direction X until it contacts the stopper I and confirm that the control lever shim thickness (lever position) is L4.

Note: Use screw (A) to fine-adjust the lever position. [Maintain a gap L2 between the screw (A) and the control lever (C).]

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=6.1+-0.5mm

----------

T1=6~9Nm(0.6~0.9kgfm) T2=5~7Nm(0.5~0.7kgfm) T3=2~3Nm(0.2~0.3kgfm) L1=1+-0.1mm L2=1~2mm L4=6.1+-0.5mm

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=6.1+-0.5mm

----------

T1=6~9Nm(0.6~0.9kgfm) T2=5~7Nm(0.5~0.7kgfm) T3=2~3Nm(0.2~0.3kgfm) L1=1+-0.1mm L2=1~2mm L4=6.1+-0.5mm

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.This maintenance is to be performed at the interval specified in the Maintenance Schedule for the engine being maintained.Before proceeding with this maintenance, first perform Daily maintenance requirements.Zinc Rods

Zinc rods are inserted in the engine's raw water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea (raw) water causes the rods to deteriorate, instead of more critical engine cooling system parts.Therefore, the zinc rods must be inspected every 50 service hours, and replaced when they have deteriorated.Depending on the engine and attachments, their location may be in the oil cooler heat exchanger bonnet, raw water heat exchanger bonnet, aftercooler lines, raw water pump and/or in the raw water lines.Inspect

Removing Old Zinc Rods

1. Remove and observe condition of all zinc rods. They are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If a rod has deteriorated, or flakes apart when tapped, install a new zinc rod.Installing New Zinc Rods

1. Unscrew or drill the existing rod from the plug base.2. Apply 9S3263 Thread Lock to the internal threads of the plug(s) holding the zinc rod(s). Install new rod(s) in the plug base(s).3. Coat the external pipe threads with 5P3413 Pipe Sealant and install the plug(s) into their proper locations in the raw water system.Marine Gear

Drain Oil and Replace Filter

With the oil warm and the engine stopped, drain the oil and replace oil filter element on a new or rebuilt marine gear at the first 50 Hour interval to ensure draining of possible large debris and particles from the oil and gear housing.Drain and change filter element with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Suspended waste particles will settle on the bottom and will not be removed with the draining oil if the oil is cold.Failure to follow this recommended procedure would result in these waste particles being recirculated through your marine gear system with the new oil. Refer to the topic in the Every 1000 Hour maintenance interval in this manual for instructions and procedure.For lubrication and maintenance requirements for your marine gear model, refer to the OEM and/or vessel manufacturer's recommendations.Marine Gear Operation, Maintenance, Warranty & Parts Support

Caterpillar encourages customers to refer to their Caterpillar dealer and/or marine gear OEM dealer for information regarding operation and maintenance for the transmission.All warranty and parts support for the marine gear (including installation and service problem resolution) will be the responsibility of the selling dealer and the marine gear OEM.Air Tank

Drain Water and Sediment

When required, or at least on a weekly basis, open the drain valve on the air tank and drain the water and sediment. Close the valve.

Zinc rods are inserted in the engine's raw water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea (raw) water causes the rods to deteriorate, instead of more critical engine cooling system parts.Therefore, the zinc rods must be inspected every 50 service hours, and replaced when they have deteriorated.Depending on the engine and attachments, their location may be in the oil cooler heat exchanger bonnet, raw water heat exchanger bonnet, aftercooler lines, raw water pump and/or in the raw water lines.Inspect

Removing Old Zinc Rods

1. Remove and observe condition of all zinc rods. They are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If a rod has deteriorated, or flakes apart when tapped, install a new zinc rod.Installing New Zinc Rods

1. Unscrew or drill the existing rod from the plug base.2. Apply 9S3263 Thread Lock to the internal threads of the plug(s) holding the zinc rod(s). Install new rod(s) in the plug base(s).3. Coat the external pipe threads with 5P3413 Pipe Sealant and install the plug(s) into their proper locations in the raw water system.Marine Gear

Drain Oil and Replace Filter

With the oil warm and the engine stopped, drain the oil and replace oil filter element on a new or rebuilt marine gear at the first 50 Hour interval to ensure draining of possible large debris and particles from the oil and gear housing.Drain and change filter element with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Suspended waste particles will settle on the bottom and will not be removed with the draining oil if the oil is cold.Failure to follow this recommended procedure would result in these waste particles being recirculated through your marine gear system with the new oil. Refer to the topic in the Every 1000 Hour maintenance interval in this manual for instructions and procedure.For lubrication and maintenance requirements for your marine gear model, refer to the OEM and/or vessel manufacturer's recommendations.Marine Gear Operation, Maintenance, Warranty & Parts Support

Caterpillar encourages customers to refer to their Caterpillar dealer and/or marine gear OEM dealer for information regarding operation and maintenance for the transmission.All warranty and parts support for the marine gear (including installation and service problem resolution) will be the responsibility of the selling dealer and the marine gear OEM.Air Tank

Drain Water and Sediment

When required, or at least on a weekly basis, open the drain valve on the air tank and drain the water and sediment. Close the valve.