Information injection-pump assembly

BOSCH

9 460 611 343

9460611343

ZEXEL

104740-2920

1047402920

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-2920 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-2920 |

| 3. | NUMBER PLATE | 146980-6600 |

| 4. | _ | 146672-7520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105140-1070 |

| 8. | Nozzle and Holder | 16600-59Y11 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-1361 |

| 11. | NOZZLE | 105000-2270 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0320 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2220 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6720 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2500 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3220 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-4220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2021 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-0720 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146538-1620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-2500 | UNION NUT |

| 82. | [1] | 146620-1400 | FLAT-HEAD SCREW |

| 83. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146561-9720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-2000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 138. | [1] | 146665-5220 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146587-6400 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2900 | COILED SPRING |

| 221. | [1] | 146934-2220 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146934-0520 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146665-4120 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146929-6320 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-0320 | COVER |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 298. | [1] | 146659-5200 | CLAMPING BAND |

| 309. | [7] | 020146-1270 | BLEEDER SCREW |

| 309. | [7] | 020146-1270 | BLEEDER SCREW |

| 309. | [7] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146685-0320 | POTENTCIOMETER |

| 310/2. | [1] | 146934-2300 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-1500 | FLAT-HEAD SCREW |

| 310/5. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 310/6. | [1] | 146614-4600 | JOINT CONNECTION |

| 311. | [2] | 146620-9700 | BLEEDER SCREW |

| 316. | [1] | 146680-4520 | DAMPER |

| 317. | [2] | 139006-4500 | BLEEDER SCREW |

| 318. | [1] | 146934-2100 | BRACKET |

| 319. | [1] | 146929-6500 | BRACKET |

| 329. | [1] | 146541-4900 | PLAIN WASHER D20&10T0.5 |

| 800S. | [1] | 146009-3920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146684-9110 | POTENTCIOMETER |

| 903. | [1] | 146672-7520 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146980-6600 | NAMEPLATE |

Include in #2:

104740-2920

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 343

9460611343

ZEXEL

104740-2920

1047402920

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

36.2

37

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

33.3

30.8

35.8

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

33.4

30.4

36.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

35.6

37.6

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

36.5

34.5

38.5

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

34.9

32.4

37.4

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

12

16

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

10.5

17.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.5

9.5

11.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.5

8.5

12.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

18.3

11.8

24.8

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.15

7.25

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

13.4

6.4

20.4

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

7.2

7.15

7.25

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

390

260

520

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

393

451

Pressure

kgf/cm2

4.3

4

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

422

383

461

Pressure

kgf/cm2

4.3

3.9

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

588

549

627

Pressure

kgf/cm2

6

5.6

6.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2400

2400

2400

Pressure

kPa

726

687

765

Pressure

kgf/cm2

7.4

6.9

7.9

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.4

3.1

3.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7.4

6.9

7.9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke

mm

9.4

8.9

9.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.78

6.68

6.88

MS dimension

mm

0.8

0.7

0.9

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

44

39

49

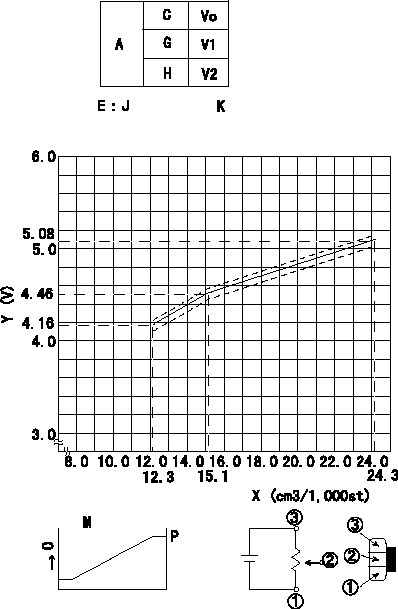

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

At N = N1 and control lever position a (corresponding to shim thickness L), measure the injection quantity, calculate the voltage from the graph, and then adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula (J)

G:Idle

H:Full speed

K:Applied voltage

X:Injection quantity (mm3/st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

----------

N1=700r/min a=11deg L=7.2mm

----------

V1=1.43+-1.75V V2=9.96++V K=10V J:V+-0.03=0.1065X+2.8519(X<15.2mm3/1,000st) V+-0.03=0.0674X+3.4462(X>=15.2mm3/1,000st)

----------

N1=700r/min a=11deg L=7.2mm

----------

V1=1.43+-1.75V V2=9.96++V K=10V J:V+-0.03=0.1065X+2.8519(X<15.2mm3/1,000st) V+-0.03=0.0674X+3.4462(X>=15.2mm3/1,000st)

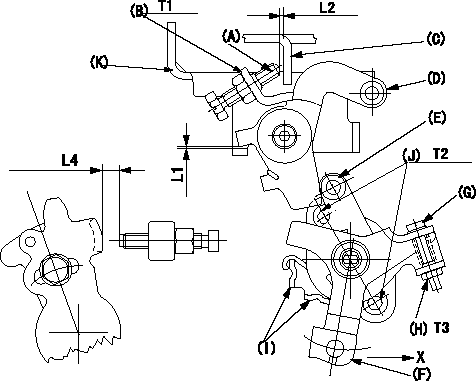

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idle position.

(2)Insert a block gauge (thickness gauge) L1 between the intermediate lever D and the bracket K. Adjust the distance between screw A and the control lever to L2 and fix using the nut.

Adjust screw (A) and fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever F in the direction X until it contacts the stopper I and tighten the socket head bolt J when the timer stroke is L3.

3. Screw (G) adjustment

(1)Adjust using the screw G so that the roller E contacts the intermediate lever D, then fix using the nut H.

(2)Pull the CSD lever F in the direction X until it contacts the stopper I and confirm that the control lever shim thickness (lever position) is L4.

Note: Use screw (A) to fine-adjust the lever position. [Maintain a gap L2 between the screw (A) and the control lever (C).]

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=5.2+-0.5mm

----------

T1=6~9Nm(0.6~0.9kgfm) T2=5~7Nm(0.5~0.7kgfm) T3=2~3Nm(0.2~0.3kgfm) L1=1+-0.1mm L2=1~2mm L4=5.2+-0.5mm

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=5.2+-0.5mm

----------

T1=6~9Nm(0.6~0.9kgfm) T2=5~7Nm(0.5~0.7kgfm) T3=2~3Nm(0.2~0.3kgfm) L1=1+-0.1mm L2=1~2mm L4=5.2+-0.5mm

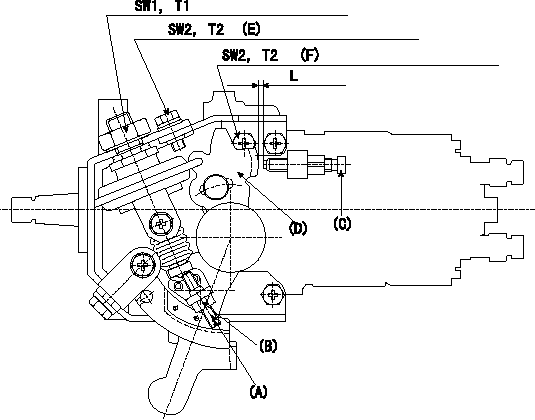

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust the dashpot adjusting screw (A) so that it contacts the pushrod, and then fix it using the locknut (B).

T3T3

Note:

(1)The adjusting screw (A) and pushrod contact faces must be smooth.

(2)Confirm that the control lever (D) returns to the idling position.

(E): 5 locations

(F): 4 locations

----------

L=6.0+-0.05mm T3=4.9~7.0Nm(0.5~0.7kgfm)

----------

SW1=22mm SW2=10mm T1=15~20Nm(1.5~2.0kgfm) T2=6~9Nm(0.6~0.9kgfm) L=6.0+-0.05mm

----------

L=6.0+-0.05mm T3=4.9~7.0Nm(0.5~0.7kgfm)

----------

SW1=22mm SW2=10mm T1=15~20Nm(1.5~2.0kgfm) T2=6~9Nm(0.6~0.9kgfm) L=6.0+-0.05mm

Information:

USE FUEL CONSUMPTION, SERVICE HOURS OR TIME INTERVAL, WHICHEVER OCCURS FIRST.Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Marine Gear - Check oil level Air Starting Motor (If Equipped) - Check motor oiler level Air Cleaner Indicator - Check Clutch Shift Collar (If Equipped) - Lubricate Raw Water Pump - Check strainer and primeEvery 1900 L (500 gal) of Fuel or 50 Hours*

Zinc Rods - Inspect/Replace Marine Gear Oil and Filter - Change on new or rebuilt marine gears at first 50 hours ONLY, then at Every 2000 Hours thereafter) Air Tank - Drain water/sedimentEvery 4750 L (1250 gal) of Fuel or 125 Hours*

Clutch Shift Collar and Bearing and Shift Lever - 1 Lubricate/Check/AdjustEvery 9500 L (2500 gal) of Fuel or 250 Hours*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters** - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive or replace coolant additive maintenance element (if equipped) Crankcase Breather - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean Valve Lash** (At First Oil Change Only) - Check/Adjust**The oil change interval is based on fuel consumption. Use fuel consumption as the best indicator of oil change interval. The sump capacity also determines oil change interval. Standard sump at 250 Hours, Deep Sump at 500 Hours. Confirm the interval with Scheduled Oil Sampling (S O S) or contact your Caterpillar dealer.Every 38 000 L (10,000 gal) of Fuel or 1000 Hours*

Marine Gear - Replace oil and filter, Clean strainer/breather, Lubricate output shaft seal Governor - Inspect/Lubricate linkage; Check/Adjust fuel ratio control and low idle - Engine Protective Devices - Inspect/CheckEvery 114 000 L (30,000 gal) of Fuel or 3000 Hours*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Cooling System - Clean/Flush/Change coolant and replace thermostat Engine Mounts and Crankshaft Vibration Damper - Inspect/Check PAR Analysis - ObtainEvery 190 000 L (50,000 gal) of Fuel or 5000 Hours*

Fuel Injection Nozzles - Test/Exchange Turbocharger, Jacket Water Pump and Raw Water Pump - Inspect/Rebuild or Exchange Alternator, Air Compressor and Starting Motors - Inspect/Rebuild or Exchange if necessary Rod Bearings1 - Inspect/Replace1Replace if fuel consumption exceeds 45.5 liter (12 U.S. gallon) per hour.OVERHAUL Every 380 000 L (100,000 gal) of Fuel or 10,000 Hours*

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plate, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump and Timing Advance - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Replace Fuel Injection Nozzles - Test Fuel Injection Pump - Test Crankshaft, Camshaft, Cam Bearings, Damper, Governor, Fuel Pump Camshaft and Fuel Rack - Inspect Oil Cooler - Clean/Test Aftercooler Core - Clean/Test Coolant Analysis - Obtain*First Perform Previous Service Hour Items

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Marine Gear - Check oil level Air Starting Motor (If Equipped) - Check motor oiler level Air Cleaner Indicator - Check Clutch Shift Collar (If Equipped) - Lubricate Raw Water Pump - Check strainer and primeEvery 1900 L (500 gal) of Fuel or 50 Hours*

Zinc Rods - Inspect/Replace Marine Gear Oil and Filter - Change on new or rebuilt marine gears at first 50 hours ONLY, then at Every 2000 Hours thereafter) Air Tank - Drain water/sedimentEvery 4750 L (1250 gal) of Fuel or 125 Hours*

Clutch Shift Collar and Bearing and Shift Lever - 1 Lubricate/Check/AdjustEvery 9500 L (2500 gal) of Fuel or 250 Hours*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters** - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive or replace coolant additive maintenance element (if equipped) Crankcase Breather - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean Valve Lash** (At First Oil Change Only) - Check/Adjust**The oil change interval is based on fuel consumption. Use fuel consumption as the best indicator of oil change interval. The sump capacity also determines oil change interval. Standard sump at 250 Hours, Deep Sump at 500 Hours. Confirm the interval with Scheduled Oil Sampling (S O S) or contact your Caterpillar dealer.Every 38 000 L (10,000 gal) of Fuel or 1000 Hours*

Marine Gear - Replace oil and filter, Clean strainer/breather, Lubricate output shaft seal Governor - Inspect/Lubricate linkage; Check/Adjust fuel ratio control and low idle - Engine Protective Devices - Inspect/CheckEvery 114 000 L (30,000 gal) of Fuel or 3000 Hours*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Cooling System - Clean/Flush/Change coolant and replace thermostat Engine Mounts and Crankshaft Vibration Damper - Inspect/Check PAR Analysis - ObtainEvery 190 000 L (50,000 gal) of Fuel or 5000 Hours*

Fuel Injection Nozzles - Test/Exchange Turbocharger, Jacket Water Pump and Raw Water Pump - Inspect/Rebuild or Exchange Alternator, Air Compressor and Starting Motors - Inspect/Rebuild or Exchange if necessary Rod Bearings1 - Inspect/Replace1Replace if fuel consumption exceeds 45.5 liter (12 U.S. gallon) per hour.OVERHAUL Every 380 000 L (100,000 gal) of Fuel or 10,000 Hours*

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plate, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump and Timing Advance - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Replace Fuel Injection Nozzles - Test Fuel Injection Pump - Test Crankshaft, Camshaft, Cam Bearings, Damper, Governor, Fuel Pump Camshaft and Fuel Rack - Inspect Oil Cooler - Clean/Test Aftercooler Core - Clean/Test Coolant Analysis - Obtain*First Perform Previous Service Hour Items