Information injection-pump assembly

BOSCH

9 460 612 867

9460612867

ZEXEL

104740-2702

1047402702

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-2702 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-2701 |

| 3. | NUMBER PLATE | 146915-6500 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1261 |

| 8. | Nozzle and Holder | 16600-0F000 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-7120 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-1800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-3300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0520 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-6420 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146752-9720 | MANIFOLD-PRESSURE COMP. |

| 67/1. | [1] | 146805-3320 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/31. | [1] | 146710-0800 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-1700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-1400 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-4100 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0000 | PLATE |

| 67/43. | [1] | 146715-0000 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-1400 | COILED SPRING |

| 67/48/1. | [1] | 146720-0000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-0100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-0200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-0300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-0400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-0500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-0600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-0700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-0800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-0900 | SPACER BUSHING L2.7 |

| 67/48/1. | [1] | 146720-1000 | SPACER BUSHING L2.9 |

| 67/48/1. | [1] | 146720-1100 | SPACER BUSHING L3.1 |

| 67/48/1. | [1] | 146720-1200 | SPACER BUSHING L3.3 |

| 67/48/1. | [1] | 146720-1300 | SPACER BUSHING L3.5 |

| 67/48/1. | [1] | 146720-1400 | SPACER BUSHING L2.8 |

| 67/48/1. | [1] | 146720-1500 | SPACER BUSHING L3.0 |

| 67/48/1. | [1] | 146720-1600 | SPACER BUSHING L3.2 |

| 67/48/1. | [1] | 146720-1700 | SPACER BUSHING L3.4 |

| 67/48/1. | [1] | 146720-1800 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146720-1900 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146720-2000 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146720-2100 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146720-2200 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146720-2300 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146720-2400 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146720-2500 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146720-2600 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146720-2700 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146720-2800 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-2900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146720-4500 | SPACER BUSHING L1.8 |

| 67/48/1. | [1] | 146720-4600 | SPACER BUSHING L1.9 |

| 67/48/1. | [1] | 146720-4700 | SPACER BUSHING L2.0 |

| 67/48/1. | [1] | 146720-4800 | SPACER BUSHING L2.1 |

| 67/48/1. | [1] | 146720-4900 | SPACER BUSHING L2.2 |

| 67/48/1. | [1] | 146720-5000 | SPACER BUSHING L2.3 |

| 67/48/1. | [1] | 146720-5100 | SPACER BUSHING L2.4 |

| 67/48/1. | [1] | 146720-5200 | SPACER BUSHING L2.5 |

| 67/48/1. | [1] | 146720-5300 | SPACER BUSHING L2.6 |

| 67/48/1. | [1] | 146725-2500 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146725-2600 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-2700 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146725-2800 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-2900 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146725-3000 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-3100 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146725-3200 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-3300 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146725-3400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-3500 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146725-3600 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-3700 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146725-3800 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-3900 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146725-4000 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-4100 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146725-4200 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-4300 | SPACER BUSHING L7.5 |

| 67/49. | [1] | 146721-3220 | COVER |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0200 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146927-2300 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146810-2520 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146536-5320 | CONTROL LEVER |

| 72B. | [1] | 146536-5420 | CONTROL LEVER |

| 72C. | [1] | 146830-6720 | CONTROL LEVER |

| 72D. | [1] | 146830-6820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146851-2920 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-9900 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0520 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-3920 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146592-6100 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-6000 | COILED SPRING |

| 221. | [1] | 146927-2620 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 224. | [1] | 146927-2700 | BRACKET |

| 230. | [1] | 146930-4220 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-6420 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 020118-1440 | BLEEDER SCREW |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146665-7620 | PIPE |

| 247. | [1] | 146665-7620 | PIPE |

| 251. | [1] | 014010-8140 | PLAIN WASHER D18&8.5T1.6 |

| 309. | [1] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146683-4920 | POTENTCIOMETER |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-1500 | FLAT-HEAD SCREW |

| 310/5. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/7. | [1] | 146661-0401 | BOOT |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146018-0420 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146683-4910 | POTENTCIOMETER |

| 906. | [1] | 146915-6500 | NAMEPLATE |

Include in #2:

104740-2702

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 867

9460612867

ZEXEL

104740-2702

1047402702

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

850

850

850

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

48.5

48

49

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_02

Pump speed

r/min

850

850

850

Boost pressure

kPa

32

30.7

33.3

Boost pressure

kgf/cm2

0.33

0.316

0.344

Boost pressure

mmHg

240

230

250

Average injection quantity

mm3/st.

57.1

56.6

57.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

48

45

51

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

850

850

850

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

48.5

47.5

49.5

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

850

850

850

Boost pressure

kPa

32

30.7

33.3

Boost pressure

kgf/cm2

0.33

0.316

0.344

Boost pressure

mmHg

240

230

250

Average injection quantity

mm3/st.

57.1

56.1

58.1

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

66.4

63.4

69.4

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

66.1

63.1

69.1

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

59.7

56.2

63.2

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

25.4

23.4

27.4

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

10

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

49.5

44.5

54.5

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2500

2500

2500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

25.4

22.4

28.4

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

435

435

435

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

435

435

435

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

95

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

95

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

435

435

435

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Overflow quantity with S/T ON

cm3/min

645

515

775

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

_02

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Overflow quantity with S/T ON

cm3/min

330

200

460

Oil temperature

degC

50

48

52

Remarks

With an O-ring

With an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Pressure with S/T ON

kPa

608

569

647

Pressure with S/T ON

kgf/cm2

6.2

5.8

6.6

Pressure with S/T OFF

kPa

451

422

480

Pressure with S/T OFF

kgf/cm2

4.6

4.3

4.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Pressure with S/T OFF

kPa

451

412

490

Pressure with S/T OFF

kgf/cm2

4.6

4.2

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Pressure with S/T OFF

kPa

628

589

667

Pressure with S/T OFF

kgf/cm2

6.4

6

6.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Timer stroke with S/T ON

mm

6.4

5.9

6.9

Timer stroke with S/T OFF

mm

3.9

3.7

4.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

850

850

850

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

2.5

2

3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

3.9

3.6

4.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

6.9

6.4

7.4

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Timer stroke with S/T OFF

mm

8.6

8.1

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

46

45.5

46.5

Timer stroke TA

mm

3.2

3

3.4

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

46

45

47

Timer stroke TA

mm

3.2

2.9

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

30

27.5

32.5

Timer stroke TA

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

850

850

850

Boost pressure

kPa

66.7

65.4

68

Boost pressure

kgf/cm2

0.68

0.666

0.694

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

30

27.5

32.5

Timer stroke TA

mm

1

0.5

1.5

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

4.4

4.2

4.6

Control lever angle alpha

deg.

10

6

14

Control lever angle beta

deg.

37

33

41

Test data Ex:

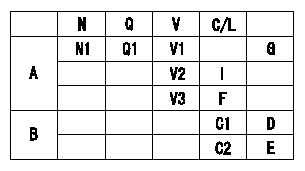

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

1. Applied voltage: Vi

2. Boost pressure = P1

3. Set the control lever at the adjusting point. Position the dummy bolt against the lever and fix.

4. Assemble the potentiometer to obtain output voltage V1 at the fixed position.

5. After mounting the potentiometer, remove the dummy bolt.

A:Performance standards

B:ON, OFF switch standard

N:Pump speed

Q:Injection quantity

V:Output voltage

C/L: control lever position

I:Idle

F:Full speed

D:OFF-->ON

E:OFF-->ON

G:Adjusting point

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.58+-0.03V

----------

N1=850r/min Q1=24.3+-1.0mm3/st V1=3.58+-0.03V V2=2.00+-0.43V V3=8.17+-0.58V C1=2.5+3.0-2.4deg C2=17.0+-5.1deg

----------

Vi=10.0V P1=0kPa(0mmHg) V1=3.58+-0.03V

----------

N1=850r/min Q1=24.3+-1.0mm3/st V1=3.58+-0.03V V2=2.00+-0.43V V3=8.17+-0.58V C1=2.5+3.0-2.4deg C2=17.0+-5.1deg

Information:

Voltage Regulator and Generator

Clean and Inspect

Before working inside the generator, make sure that the starter motor can not be activated by any automatic or manual signal.When the engine-generator is operating, voltages up to 600V are present in these areas near or on the regulator:1. The regulator terminal strip2. The excitation transformer terminal strip (self-excited generator only).Do not short these terminals to ground with any part of the body or any conductive material. Loss of life or injury could result from electrical shock or injury from molten metal.An electrical shock can be received from the regulator capacitor (C1) when the engine-generator is not in operation. To avoid possible injury, discharge the stored charge using an 100 ohm resistor across C1 terminals.

Electronic components in the regulator can be damaged during generator operation if contact is made between the part and ground.

If Moisture is allowed to remain in contact with an electrical winding, some of the moisture will eventually be absorbed. This will lower the resistance of the winding insulation. The insulation used on the windings of Caterpillar generators is moisture resistant, but constant exposure to moisture will gradually lower the insulation's resistance.Dirt can make the problem worse because it can hold the moisture in contact with the insulation. Salt (from sea air) can also make the problem much worse. This is because salt tends to absorb moisture from the air. When the salt and moisture combine, they make a good electrical conductor.Clean the voltage regulator and generator of dirt and debris. Use a brush to loosen accumulations of dirt and a vacuum system for removal. Use of compressed air is not recommended, because of moisture present in the form of condensate.Carbon tracking on insulators can be caused by dirt or loose connections. These carbon paths must be cleaned or the insulators replaced. Failure to correct a carbon tracking problem will eventually result in a short in the electrical circuit.Visually check for loose or broken wires and connections. Check the wires and connections on the regulator assembly. Check that all circuit boards are fully plugged in their sockets. Check all wires and connections in the generator. Make any necessary repairs to the wiring as required. Refer to the "Electric Set Generator Service Manual" for testing and adjusting or disassembly and assembly procedures.Space Heaters

The SR4 generator can operate in high humidity conditions without problems. However, problems can occur when the generator is idle and the surrounding air is warmer than the generator. Moisture can form on the windings and result in poor performance and even result in damage to the windings. Whenever the generator is not in use, insure that the space heaters are in operation.An external source of either 115 or 230 (200 v at 50 Hz) volts A.C. is required to operate the space heaters. Space Heater Connection to External Source H1, H2, H3, H4. Terminal Strip Terminals If 115 VAC source is available, connect

Clean and Inspect

Before working inside the generator, make sure that the starter motor can not be activated by any automatic or manual signal.When the engine-generator is operating, voltages up to 600V are present in these areas near or on the regulator:1. The regulator terminal strip2. The excitation transformer terminal strip (self-excited generator only).Do not short these terminals to ground with any part of the body or any conductive material. Loss of life or injury could result from electrical shock or injury from molten metal.An electrical shock can be received from the regulator capacitor (C1) when the engine-generator is not in operation. To avoid possible injury, discharge the stored charge using an 100 ohm resistor across C1 terminals.

Electronic components in the regulator can be damaged during generator operation if contact is made between the part and ground.

If Moisture is allowed to remain in contact with an electrical winding, some of the moisture will eventually be absorbed. This will lower the resistance of the winding insulation. The insulation used on the windings of Caterpillar generators is moisture resistant, but constant exposure to moisture will gradually lower the insulation's resistance.Dirt can make the problem worse because it can hold the moisture in contact with the insulation. Salt (from sea air) can also make the problem much worse. This is because salt tends to absorb moisture from the air. When the salt and moisture combine, they make a good electrical conductor.Clean the voltage regulator and generator of dirt and debris. Use a brush to loosen accumulations of dirt and a vacuum system for removal. Use of compressed air is not recommended, because of moisture present in the form of condensate.Carbon tracking on insulators can be caused by dirt or loose connections. These carbon paths must be cleaned or the insulators replaced. Failure to correct a carbon tracking problem will eventually result in a short in the electrical circuit.Visually check for loose or broken wires and connections. Check the wires and connections on the regulator assembly. Check that all circuit boards are fully plugged in their sockets. Check all wires and connections in the generator. Make any necessary repairs to the wiring as required. Refer to the "Electric Set Generator Service Manual" for testing and adjusting or disassembly and assembly procedures.Space Heaters

The SR4 generator can operate in high humidity conditions without problems. However, problems can occur when the generator is idle and the surrounding air is warmer than the generator. Moisture can form on the windings and result in poor performance and even result in damage to the windings. Whenever the generator is not in use, insure that the space heaters are in operation.An external source of either 115 or 230 (200 v at 50 Hz) volts A.C. is required to operate the space heaters. Space Heater Connection to External Source H1, H2, H3, H4. Terminal Strip Terminals If 115 VAC source is available, connect