Information injection-pump assembly

BOSCH

9 460 612 860

9460612860

ZEXEL

104740-2550

1047402550

NISSAN

1670088N10

1670088n10

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-2550 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-2550 |

| 3. | NUMBER PLATE | 146915-0000 |

| 4. | _ | 479774-3820 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105140-1070 |

| 8. | Nozzle and Holder | 16600-59Y11 |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.7{130} |

| 10. | NOZZLE-HOLDER | 105071-1361 |

| 11. | NOZZLE | 105000-2270 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0320 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2220 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6220 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2700 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 50. | [1] | 146403-3420 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3220 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-2720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-6920 | GOVERNOR COVER |

| 67/1. | [1] | 146805-5920 | GOVERNOR COVER |

| 67/13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/91. | [1] | 146928-7800 | BRACKET |

| 67/92. | [1] | 139006-4500 | BLEEDER SCREW |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-2520 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146538-0820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 82. | [1] | 146620-1400 | FLAT-HEAD SCREW |

| 83. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146561-9520 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0220 | OVER FLOW VALVE |

| 137. | [2] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 138. | [1] | 146665-0220 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 214. | [1] | 146542-5000 | BUSHING |

| 216. | [1] | 146542-5100 | BUSHING |

| 217. | [1] | 146541-2900 | SLOTTED WASHER |

| 218. | [1] | 146592-2100 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-3600 | COILED SPRING |

| 221. | [1] | 146929-8320 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146929-5420 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 139512-0200 | GASKET D18.5&12.2T1.00 |

| 246. | [1] | 139812-0500 | EYE BOLT |

| 247. | [1] | 146665-3220 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146612-2120 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-9420 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 287. | [1] | 020146-1440 | BLEEDER SCREW M6P1L14 |

| 309. | [8] | 020146-1270 | BLEEDER SCREW |

| 309. | [8] | 020146-1270 | BLEEDER SCREW |

| 309. | [8] | 020146-1270 | BLEEDER SCREW |

| 309. | [8] | 020146-1270 | BLEEDER SCREW |

| 309. | [8] | 020146-1270 | BLEEDER SCREW |

| 310. | [1] | 146683-4421 | POTENTCIOMETER |

| 310/2. | [1] | 146929-8100 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146648-9200 | JOINT CONNECTION |

| 310/4B. | [1] | 146648-9300 | JOINT CONNECTION |

| 310/4C. | [1] | 146648-9400 | JOINT CONNECTION |

| 310/4D. | [1] | 146648-9500 | JOINT CONNECTION |

| 310/4E. | [1] | 146648-9600 | JOINT CONNECTION |

| 310/4F. | [1] | 146648-9700 | JOINT CONNECTION |

| 310/4G. | [1] | 146648-9800 | JOINT CONNECTION |

| 310/4H. | [1] | 146648-9900 | JOINT CONNECTION |

| 310/4I. | [1] | 146649-0000 | JOINT CONNECTION |

| 310/4J. | [1] | 146649-0100 | JOINT CONNECTION |

| 310/4K. | [1] | 146649-0200 | JOINT CONNECTION |

| 310/4L. | [1] | 146649-0300 | JOINT CONNECTION |

| 311. | [2] | 146620-7300 | BLEEDER SCREW |

| 316. | [1] | 146680-4520 | DAMPER |

| 318. | [1] | 146929-8000 | BRACKET |

| 319. | [1] | 146928-7900 | BRACKET |

| 329. | [1] | 146541-4900 | PLAIN WASHER D20&10T0.5 |

| 800S. | [1] | 146009-3920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146683-6710 | POTENTCIOMETER |

| 903. | [1] | 479774-3820 | PULSE GENERATOR |

| 903/6. | [1] | 479773-6500 | O-RING |

| 906. | [1] | 146915-0000 | NAMEPLATE |

Include in #2:

104740-2550

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 860

9460612860

ZEXEL

104740-2550

1047402550

NISSAN

1670088N10

1670088n10

Zexel num

Bosch num

Firm num

Name

104740-2550

9 460 612 860

1670088N10 NISSAN

INJECTION-PUMP ASSEMBLY

CD20 * K 11CJ VE4 VE

CD20 * K 11CJ VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

35.3

34.9

35.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.1

28.6

33.6

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

30.6

27.6

33.6

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

35.3

34.3

36.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

35.4

33.4

37.4

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

34.5

32

37

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

12

16

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

10.5

17.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.5

9.5

11.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.5

8.5

12.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

15.1

8.6

21.6

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.9

8.85

8.95

Remarks

From idle

From idle

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

10.3

3.3

17.3

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

8.9

8.85

8.95

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

440

310

570

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

324

295

353

Pressure

kgf/cm2

3.3

3

3.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

373

334

412

Pressure

kgf/cm2

3.8

3.4

4.2

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

520

471

569

Pressure

kgf/cm2

5.3

4.8

5.8

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2400

2400

2400

Pressure

kPa

637

588

686

Pressure

kgf/cm2

6.5

6

7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.9

1.6

2.2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.6

5.1

6.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.78

6.68

6.88

MS dimension

mm

0.8

0.7

0.9

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

44

39

49

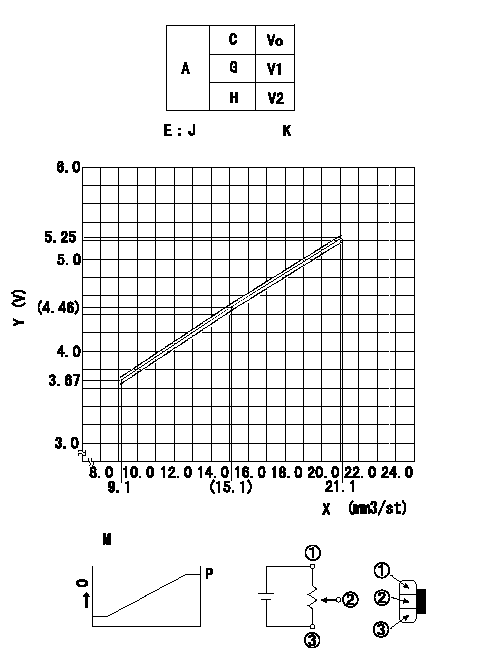

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula

G:Idle

H:Full speed

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

----------

N1=700r/min a=13.9deg L=8.9+-0.05mm Q1=15.1cm3/1,000st V3=4.46V

----------

V1=1.7--V V2=9.96++V K=10V J=V+-0.03=0.13121X+2.4787

----------

N1=700r/min a=13.9deg L=8.9+-0.05mm Q1=15.1cm3/1,000st V3=4.46V

----------

V1=1.7--V V2=9.96++V K=10V J=V+-0.03=0.13121X+2.4787

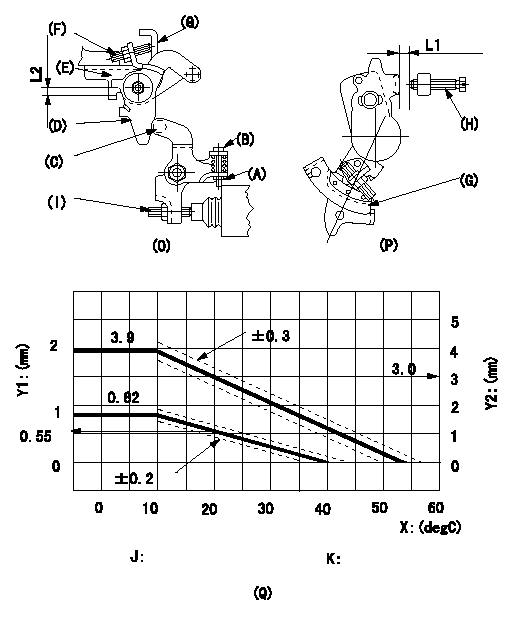

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle from the graph in Fig. 3 (Q).

(2)(1) Adjust using the screw (I) so that the timer advance angle determined in item (1) is obtained.

2. Setting the intermediate lever position (refer to fig 1 and fig 2)

(1)Insert a block gauge L1 between the idling set screw (H) and the control lever (G).

(2)Insert a shim of thickness L2 mm between the intermediate lever (D) and the intermediate lever bracket (E). Ensure the screw (F) contacts the control lever (G), then fix the nut.

3. W-CSD lever adjustment [refer to fig 1 (O) and fig 2 (P)]

(1)After completing (2) above, remove the block gauge L3 and the shim with the thickness L4.

(2)Insert a block gauge L5 determined from the graph (L-t) in figure 3 (Q) between the idling set screw (H) and the control lever (G).

(3)Adjust the screw (B) until the screw (F) contacts the control lever (G). Then fix locknut (A).

Caution: The temperature of the wax at adjustment must not exceed a.

X:Temperature t (deg C)

Y1:Timer lift TA (mm)

Y2:Control lever L dimension (mm; control lever position)

J:Graph TA-t:

t (deg C) <= 10: TA = 0.82

10 <= t (deg C) <= 20: TA =-0.027t + 1.09

20 <= t (deg C) <= 40: TA = -0.0275t + 1.1

K:Graph L-t

t (deg C) <= 10: L = 3.9

10 <= t (deg C) <= 30: L =-0.09t + 4.8

20 <= t (deg C) <= 54.3: L = -0.086t + 4.68

----------

L1=3.0+-0.05mm L2=5.3+-0.05mm L3=3.0mm L4=5.3mm L5=L+-0.05mm a=30degC

----------

L1=3.0+-0.05mm L2=5.3mm

----------

L1=3.0+-0.05mm L2=5.3+-0.05mm L3=3.0mm L4=5.3mm L5=L+-0.05mm a=30degC

----------

L1=3.0+-0.05mm L2=5.3mm

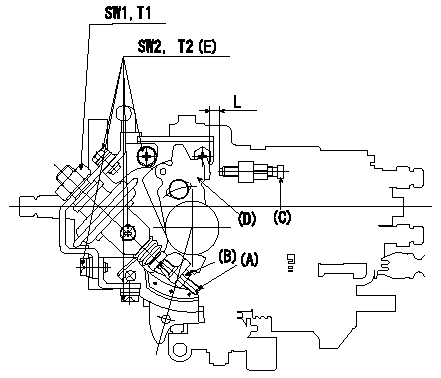

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust so that the dashpot adjusting screw (A) contacts the pushrod. Then, fix using the locknut (B) (Tightening torque T3).

3. Ensure the adjusting screw or dashpot does not stick or come loose.

4. Confirm that the control lever returns to the idling position.

(E) 6 locations

----------

T3=4.9~7N-m(0.5~0.7kgf-m) L=6.0+-0.05mm

----------

T1=15.0~20.0N-m(1.5~2.0kgf-m) T2=6.0~9.0N-m(0.6~0.9kgf-m) SW1=SW22 SW2=SW10 L=6.0+-0.05mm

----------

T3=4.9~7N-m(0.5~0.7kgf-m) L=6.0+-0.05mm

----------

T1=15.0~20.0N-m(1.5~2.0kgf-m) T2=6.0~9.0N-m(0.6~0.9kgf-m) SW1=SW22 SW2=SW10 L=6.0+-0.05mm

Information:

7. Remove inner fuel lines (13). 8. Remove Jacobs washers (14) and Jacobs shims (15) from the Jacobs stud assemblies. 9. Remove bolt (17) and two Jacobs stud assemblies (16) that hold the rocker shaft assembly to the head. Remove rocker shaft assembly (18). 10. Remove Jacobs exhaust valve bridges (20) from the exhaust valves only. The intake valves have the Caterpillar intake valve bridges. Remove the Caterpillar intake valve bridges (19).Install Jacobs Engine Brake

Do each step for each end of the engine. The front half is shown.1. Put clean engine oil on the bridges and dowels.2. Install Jacobs exhaust valve bridges (20) and the Caterpillar intake valve bridges (19) on the dowels.3. Keep hand pressure on the bridges, and turn the adjustment screw clockwise until contact is made with the valve stem. Turn the screw an extra 20 ° to 30 °. This will make the dowel straight in the guide and compensate for gap (slack) in the threads. Hold the adjustment screw in this position, and tighten the locknut to a torque of 28 4 N m (21 3 lb.ft.). 4. Put rocker shaft assembly (18) in position on the cylinder head. 5. Install Jacobs washers (21) on the Jacobs stud assemblies (16). Put clean oil on the threads, and install washer and bolt (17) and Jacobs stud assemblies (16). Tighten the center bolt and Jacobs stud assemblies in increments of 70 N m (50 lb.ft.) each until a final torque of 450 N m (330 lb.ft.) is obtained.6. Make an adjustment to the valves to have a clearance of .015 (0.38 mm) for the intake valves and .030 (0.76 mm) for the exhaust valves. Tighten the locknuts to a torque of 28 4 N m (21 3 lb.ft.), and check the valve clearance again. See Testing And Adjusting for the correct procedure. 7. Install a new Jacobs O-ring seal (22) on the Jacobs oil supply adapter in the rocker shaft assembly. Put clean oil on the Jacobs O-ring seal.

Do not cause damage to the O-ring seals on the inner fuel lines.

8. Install inner fuel lines (13). Tighten the fuel line nuts to a torque of 40 7 N m (30 5 lb.ft.) with tooling (A) and (B). The Jacobs brake for the 3406B Truck Engine has only one support bracket (11).9. Put Jacobs support brackets (11) in position as shown. Put oil on the threads of Jacobs bolts (12). Install the washers on the Jacobs bolts. Install Jacobs bolts (12) that hold the Jacobs support bracket in place. Tighten the Jacobs bolts to a torque of 450 N m (330 lb.ft.). 10. Install Jacobs washers (14) on the Jacobs stud assemblies.

Be extra careful not to cause damage to the Jacobs oil supply adapter O-ring seal when the Jacobs brake housing assembly is installed.

The brake housing assembly with the mark "FRONT" on it must

Do each step for each end of the engine. The front half is shown.1. Put clean engine oil on the bridges and dowels.2. Install Jacobs exhaust valve bridges (20) and the Caterpillar intake valve bridges (19) on the dowels.3. Keep hand pressure on the bridges, and turn the adjustment screw clockwise until contact is made with the valve stem. Turn the screw an extra 20 ° to 30 °. This will make the dowel straight in the guide and compensate for gap (slack) in the threads. Hold the adjustment screw in this position, and tighten the locknut to a torque of 28 4 N m (21 3 lb.ft.). 4. Put rocker shaft assembly (18) in position on the cylinder head. 5. Install Jacobs washers (21) on the Jacobs stud assemblies (16). Put clean oil on the threads, and install washer and bolt (17) and Jacobs stud assemblies (16). Tighten the center bolt and Jacobs stud assemblies in increments of 70 N m (50 lb.ft.) each until a final torque of 450 N m (330 lb.ft.) is obtained.6. Make an adjustment to the valves to have a clearance of .015 (0.38 mm) for the intake valves and .030 (0.76 mm) for the exhaust valves. Tighten the locknuts to a torque of 28 4 N m (21 3 lb.ft.), and check the valve clearance again. See Testing And Adjusting for the correct procedure. 7. Install a new Jacobs O-ring seal (22) on the Jacobs oil supply adapter in the rocker shaft assembly. Put clean oil on the Jacobs O-ring seal.

Do not cause damage to the O-ring seals on the inner fuel lines.

8. Install inner fuel lines (13). Tighten the fuel line nuts to a torque of 40 7 N m (30 5 lb.ft.) with tooling (A) and (B). The Jacobs brake for the 3406B Truck Engine has only one support bracket (11).9. Put Jacobs support brackets (11) in position as shown. Put oil on the threads of Jacobs bolts (12). Install the washers on the Jacobs bolts. Install Jacobs bolts (12) that hold the Jacobs support bracket in place. Tighten the Jacobs bolts to a torque of 450 N m (330 lb.ft.). 10. Install Jacobs washers (14) on the Jacobs stud assemblies.

Be extra careful not to cause damage to the Jacobs oil supply adapter O-ring seal when the Jacobs brake housing assembly is installed.

The brake housing assembly with the mark "FRONT" on it must

Have questions with 104740-2550?

Group cross 104740-2550 ZEXEL

Nissan

Mazda

Nissan

Nissan

Nissan

104740-2550

9 460 612 860

1670088N10

INJECTION-PUMP ASSEMBLY

CD20

CD20