Information injection-pump assembly

ZEXEL

104740-2373

1047402373

NISSAN

167001C310

167001c310

Rating:

Cross reference number

ZEXEL

104740-2373

1047402373

NISSAN

167001C310

167001c310

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.8

31.3

32.3

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

Full

Full

Injection timing adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

43.35

42

44.7

Boost pressure

mmHg

325

315

335

Average injection quantity

mm3/st.

45.1

44.6

45.6

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

2700

2700

2700

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

21.4

13.9

28.9

Injection timing adjustment_04

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

37.5

36

39

Injection timing adjustment_05

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

45.9

42.4

49.4

Injection timing adjustment_06

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

47.6

44.1

51.1

Injection timing adjustment_07

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

51.3

48.3

54.3

Injection timing adjustment_08

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

51.6

48.6

54.6

Injection timing adjustment_09

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.8

30.8

32.8

Remarks

Full

Full

Injection timing adjustment_10

Pump speed

r/min

900

900

900

Boost pressure

kPa

43.35

42

44.7

Boost pressure

mmHg

325

315

335

Average injection quantity

mm3/st.

45.1

44.1

46.1

Remarks

CBS

CBS

Injection timing adjustment_11

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

35.7

33.7

37.7

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

37.5

36.5

38.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2950

2950

2950

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

6

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

10.5

9.5

11.5

Basic

*

Governor adjustment_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

10.5

9

12

Boost compensator adjustment

Pump speed

r/min

700

700

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.4

11.9

24.9

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

65

60

70

Basic

*

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Overflow quantity

cm3/min

378

246

510

Stop lever angle

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

382.5

353

412

Pressure

kgf/cm2

3.9

3.6

4.2

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

382.5

353

412

Pressure

kgf/cm2

3.9

3.6

4.2

Stop lever angle_04

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

490.5

461

520

Pressure

kgf/cm2

5

4.7

5.3

Stop lever angle_05

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

0000001101

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

3

2.8

3.2

Basic

*

_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

1

0.3

1.7

_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

3

2.7

3.3

_04

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

5.9

5.4

6.4

_05

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

8.2

7.6

8.8

_06

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

8.9

8.4

9.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.9

25.4

26.4

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.9

24.9

26.9

Timer stroke variation dT

mm

0.35

0

0.7

_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

17.5

16

19

Timer stroke variation dT

mm

0.8

0.3

1.3

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.29

6.19

6.39

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.6

4.4

4.8

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

9

8.5

9.5

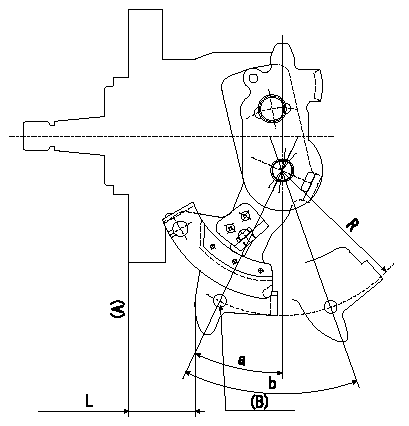

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure the dimension L from the lever tip to the flange face (A).

2. Measure the lever angle from the pin hole R (plate).

(B): lever angle measuring hole

Alpha = a

beta: b

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

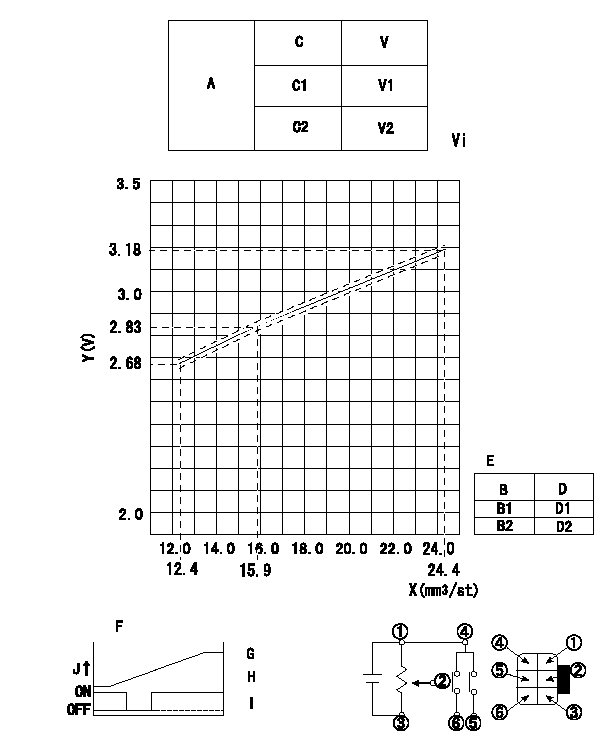

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N1 and a control lever position a from idle (gap L1), measure the injection quantity and convert it to a voltage value. Then adjust the potentiometer.

Voltage conversion formula: V+-0.03 = 0.04163Q+2.1637

A:Potentiometer performance standards

C:Position of the control lever

C1:Idle

C2:Full speed

V:Potentiometer voltage

E:Standards for the potentiometer's ON - OFF switch

B:Conversion point

B1:OFF-->ON

B2:OFF-->ON

D:Lever opening (from idle)

Vi:Applied voltage

F:Connecting diagram for the potentiometer

G:Output when (2) and (3) connected.

H:When (4) or (6) connected: switch OFF to ON.

I:When (4) or (5) connected: switch ON to OFF.

J:Output

----------

N1=700r/min a=9deg L1=5.95mm

----------

V1=1.43+-0.4V V2=8.43+-1.47V Vi=10V D1=5+-3deg D2=21.5++deg

----------

N1=700r/min a=9deg L1=5.95mm

----------

V1=1.43+-0.4V V2=8.43+-1.47V Vi=10V D1=5+-3deg D2=21.5++deg

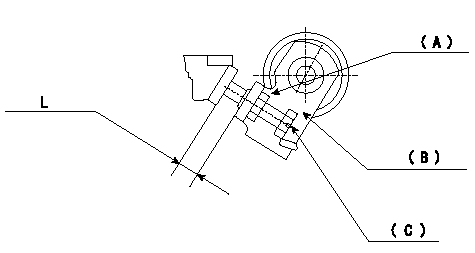

0000002001 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust adjusting bolt so that the starting injection quantity is within the standard.

Fix using nut.

(A): Lock nut.

(B): Stopping lever

(C): Adjustment bolt

----------

----------

L=5~10mm

----------

----------

L=5~10mm

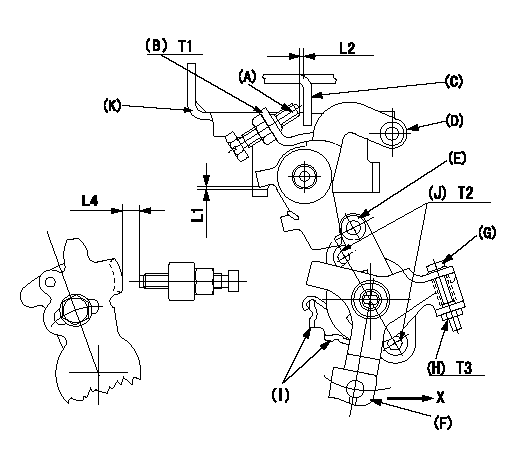

0000002101 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idle position.

(2)Insert a block gauge (thickness gauge) L1 between the intermediate lever (D) and the bracket (K). Adjust screw (A) so that the distance between screw A and the control lever to L2 and fix using the nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever F in the direction X until it contacts the stopper I and tighten the socket head bolt J when the timer stroke is L3.

3. Screw (G) adjustment

(1)Adjust using the screw G so that the roller E contacts the intermediate lever D, then fix using the nut H.

(2)Pull the CSD lever F in the direction X until it contacts the stopper I and confirm that the control lever shim thickness (lever position) is L4.

Note: Use screw (A) to fine-adjust the lever position. [Maintain a gap L2 between the screw (A) and the control lever (C).]

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=3.8+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1+-0.1mm L2=1~2mm L4=3.8+-0.5mm

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=3.8+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1+-0.1mm L2=1~2mm L4=3.8+-0.5mm

Information:

Start By:a. remove engine

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Unplug the connector and remove speed pickup (1) to prevent damage to the unit.2. Install tool (A) on the flywheel as shown and fasten a hoist.3. Remove bolts (2) and flywheel (3). The weight of the flywheel is 72 kg (160 lb.).4. If necessary, remove the ring gear from the flywheel with a hammer and punch. The following steps are for the installation of the flywheel.

The ring gear must be installed with the chamfered side of the teeth up as shown in the inset of illustration A89844P2. This will put the chamfered side of the gear teeth toward the starter when the flywheel is installed so the starter will engage correctly.

1. Heat ring gear (4) to a maximum temperature of 320° C (608° F). Install the ring gear. 2. Install tooling (A) on the flywheel in the same position it was during removal. Install two 5/8" - 18 NF guide bolts in the crankshaft if necessary.3. Make an alignment of timing mark (5) on the crankshaft and timing mark (6) on the flywheel. Hold flywheel (3) in position and install bolts (2). Tighten bolts (2) to a torque of 205 27 N m (151 20 lb ft).4. Remove tool (A).5. Install speed pickup (1). Hand tighten speed pickup (1) until it makes contact with the flywheel. Loosen speed pickup (1) one half turn (180°) after contacting the flywheel. Tighten the locknut on speed pickup (1) and the connect wiring harness.End By:a. install engine

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Unplug the connector and remove speed pickup (1) to prevent damage to the unit.2. Install tool (A) on the flywheel as shown and fasten a hoist.3. Remove bolts (2) and flywheel (3). The weight of the flywheel is 72 kg (160 lb.).4. If necessary, remove the ring gear from the flywheel with a hammer and punch. The following steps are for the installation of the flywheel.

The ring gear must be installed with the chamfered side of the teeth up as shown in the inset of illustration A89844P2. This will put the chamfered side of the gear teeth toward the starter when the flywheel is installed so the starter will engage correctly.

1. Heat ring gear (4) to a maximum temperature of 320° C (608° F). Install the ring gear. 2. Install tooling (A) on the flywheel in the same position it was during removal. Install two 5/8" - 18 NF guide bolts in the crankshaft if necessary.3. Make an alignment of timing mark (5) on the crankshaft and timing mark (6) on the flywheel. Hold flywheel (3) in position and install bolts (2). Tighten bolts (2) to a torque of 205 27 N m (151 20 lb ft).4. Remove tool (A).5. Install speed pickup (1). Hand tighten speed pickup (1) until it makes contact with the flywheel. Loosen speed pickup (1) one half turn (180°) after contacting the flywheel. Tighten the locknut on speed pickup (1) and the connect wiring harness.End By:a. install engine