Information injection-pump assembly

ZEXEL

104740-2176

1047402176

Rating:

Cross reference number

ZEXEL

104740-2176

1047402176

Zexel num

Bosch num

Firm num

Name

104740-2176

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

ON

Injection timing adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

31

30.6

31.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

29.4

27.4

31.4

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

28.3

26.3

30.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

31

30

32

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

29.8

27.8

31.8

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

29.8

27.8

31.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.8

12.8

16.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.8

11.3

18.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

9.6

8.6

10.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

9.6

7.6

11.6

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

13.5

7

20

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.7

5.7

5.7

Remarks

From idle

From idle

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

9.6

2.6

16.6

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.7

5.7

5.7

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

55

75

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

55

75

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

440

310

570

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

412

383

441

Pressure with S/T ON

kgf/cm2

4.2

3.9

4.5

Pressure with S/T OFF

kPa

353

304

402

Pressure with S/T OFF

kgf/cm2

3.6

3.1

4.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

412.5

375

450

Pressure

kgf/cm2

4.2

3.8

4.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1400

1400

1400

Pressure

kPa

510

470

550

Pressure

kgf/cm2

5.2

4.8

5.6

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2400

2400

2400

Pressure

kPa

735

695

775

Pressure

kgf/cm2

7.5

7.1

7.9

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

4.4

4.2

4.6

Timer stroke with S/T OFF

mm

3.2

2.8

3.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

ON

ON

_02

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

4.4

4.1

4.7

Timer stroke with S/T OFF

mm

3.2

2.7

3.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1400

1400

1400

Timer stroke with S/T ON

mm

6.4

5.9

6.9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke with S/T ON

mm

10.65

10.2

11.1

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.78

6.68

6.88

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

42

37

47

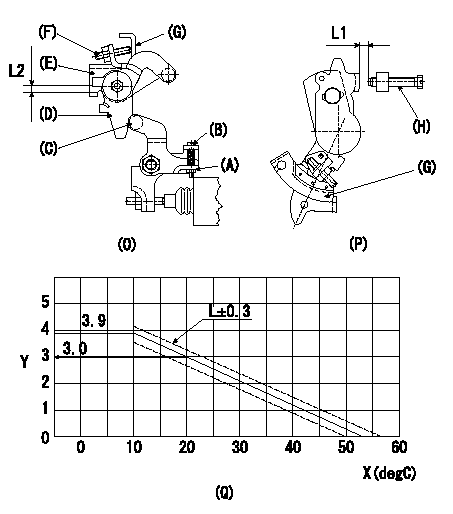

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N and with the control lever angle at a from the idle position (clearance L), convert the injection quantity obtained to a voltage value using the graph and adjust the potentiometer.

Vo:Output voltage

Q:Injection quantity

A:Performance standards

C:Position of the control lever

G:Idle

H:Full speed

E:J = formula V+-0.03 = 0.0656Q+3.1852 14.4 <= Q <= 19.5 (mm3/st)

V+-0.03 = 0.1020Q + 2.6597 11.1<= Q <= 14.4 mm3/st)

V+-0.03 = 0.1103Q + 2.5678 7.5 <= Q <= 11.1 (mm3/st)

K = Vi: applied voltage

X:Injection quantity (mm3/st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

----------

N=700(r/min) a=9(deg) L=5.7(mm) Vi=10(V)

----------

V1=1.47+-0.5(V) V2=(10.0(V))

----------

N=700(r/min) a=9(deg) L=5.7(mm) Vi=10(V)

----------

V1=1.47+-0.5(V) V2=(10.0(V))

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Set the intermediate lever [Refer to (O), (P)]

(1)Insert a block gauge L1+-0.05 mm between the idling set screw (H) and the control lever (G).

2. Insert a shim thickness L2+-0.05 (mm) between the intermediate lever D and the intermediate lever bracket E. Position screw F against the control lever G and tighten the nut.

W-CSD lever adjustment (refer to (O), (P))

(1)After completing (1) above, remove the block gauge L1 and the shim with the thickness L2.

(2)Insert a block gauge thickness L3 determined from the graph (Q) between the idling set screw (H) and the control lever (G).

(3)Adjust the screw (B) until the screw (F) contacts the control lever (G). Then fix locknut (A).

(4)The temperature of the wax at adjustment must not exceed a.

X:Temperature theta (deg C)

Y:Control lever L dimension (mm; control lever position)

Q:L-theta graph

theta (deg C) <= 10: L = 3.9

10 <= theta (deg C) <= 30 L = -0.09 theta + 4.8

30 <= theta (deg C) <= 54.3 L = -0.086 theta + 4.68

----------

L1=3.0(mm) L2=5.3(mm) L3=L1+-0.05(mm) a=30(degC)

----------

L1=3.0(mm) L2=5.3(mm)

----------

L1=3.0(mm) L2=5.3(mm) L3=L1+-0.05(mm) a=30(degC)

----------

L1=3.0(mm) L2=5.3(mm)

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Loosen hose clamps and slide hose (1) down on the tube assembly. 2. Remove tube assembly (4).3. Disconnect hose assembly (3), loosen two clamps and slide hose (2) on tube assembly. 4. Remove bolts (5). 5. Remove the supply tube (6) and drain tube (7) and the gaskets. 6. Disconnect tube assembly (8) from the aftercooler housing and remove bolts (9).7. Attach a hoist to the cylinder head lift brackets. 8. Remove head bolts (10) and the cylinder head from the engine block. The weight of the cylinder head assembly is 177 kg (390 lb).

Do not set the cylinder head on a flat surface because of possible damage to the fuel injection nozzle tips.

Install Cylinder Head

When the cylinder head is removed, a new spacer plate gasket must be installed. See the topic, Remove And Install Spacer Plate, in this manual. 1. Clean the surfaces of the cylinder head and the cylinder block that make contact with each other. Make sure the surfaces are clean and dry. Install a new dry gasket (2) on the cylinder block.2. Fasten a hoist to the cylinder head (1) and put it on position on the cylinder block.3. Put 2P2506 Thread Lubricant on all the head bolts and rocker shaft bolts except bolt (25). Install the head bolts and washers that hold the head in place. Do not tighten bolts at this time.4. Loosen the adjusting screws on the rocker arms for valve clearance. This will prevent a bent valve or push rod at installation. 5. Install push rods (4) and rocker shaft assembly (3). Install the bolts and washers that hold the rocker shaft in place. 6. Tighten the bolts as follows:a. Tighten bolts 1 through 26 in number sequence to a torque of 155 N m (115 lb ft).b. Tighten bolts 1 through 26 again in number sequence to a torque of 250 17 N m (185 13 lb ft).c. Tighten bolts 1 through 26 again in number sequence (hand tighten only) to a torque of 250 17 N m (185 13 lb ft).d. Tighten bolts A through G in letter sequence (hand tighten only) to a torque of 43 7 N m (32 5 lb ft). 6. Make an adjustment until the intake valve clearance is 0.38 mm (.015 in) and the exhaust valve clearance is 0.64 mm (.025 in). Tighten the locknuts (5) for the adjusting screws to a torque of 29 7 N m (21 5 lb ft).7. Connect tube assembly (6) and install the bolts to fasten clips (7). 8. Inspect the turbocharger cartridge gaskets and make replacements if necessary. Install gaskets and the turbocharger supply tube assembly (8) and drain tube assembly (9). 9. Make sure the gasket for the water pump bypass elbow is in good condition and install two bolts (11) to fasten elbow (12) to cylinder

Have questions with 104740-2176?

Group cross 104740-2176 ZEXEL

104740-2176

INJECTION-PUMP ASSEMBLY