Information injection-pump assembly

ZEXEL

104740-1700

1047401700

ISUZU

8943260770

8943260770

Rating:

Cross reference number

ZEXEL

104740-1700

1047401700

ISUZU

8943260770

8943260770

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

49.3

48.8

49.8

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

14

10.5

17.5

Injection timing adjustment_03

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

40.7

38.2

43.2

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

49.3

48.3

50.3

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

48.8

46.3

51.3

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

14

11

17

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

10.3

8.3

12.3

Governor adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1750

1750

1750

Pressure

kPa

588.5

569

608

Pressure

kgf/cm2

6

5.8

6.2

Basic

*

Stop lever angle_02

Pump speed

r/min

1750

1750

1750

Pressure

kPa

588.5

569

608

Pressure

kgf/cm2

6

5.8

6.2

Stop lever angle_03

Pump speed

r/min

2150

2150

2150

Pressure

kPa

666.5

637

696

Pressure

kgf/cm2

6.8

6.5

7.1

0000001101

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

4.2

4

4.4

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

2

1.5

2.5

_03

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

4.2

3.8

4.6

_04

Pump speed

r/min

2150

2150

2150

Timer stroke

mm

5.85

5.3

6.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

34

33.5

34.5

Timer stroke variation dT

mm

0.8

0.6

1

Basic

*

_02

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

34

33

35

Timer stroke variation dT

mm

0.8

0.5

1.1

_03

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

25

23.5

26.5

Timer stroke variation dT

mm

1.6

1.1

2.1

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.2

0.18

0.22

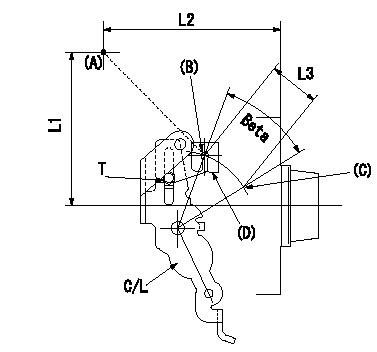

Control lever angle alpha

deg.

-2

-6

2

Control lever angle beta

deg.

38

33

43

Test data Ex:

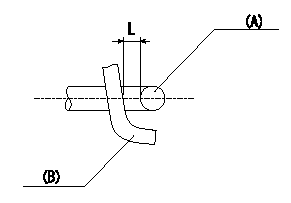

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 {P2} to the actuator and confirm that it moves through its full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

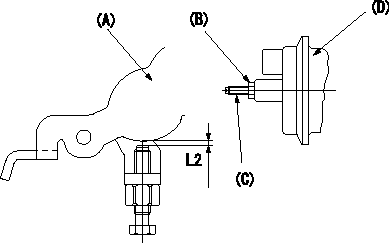

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

Becomes L2 when negative pressure P3 {P4} applied to the actuator.

To adjust the stroke adjust the actuator's stroke adjusting screw (C).

(A) Control lever

(B): lock nut

(C): stroke adjusting screw

(D): Actuator

----------

L2=0.56+-0.2mm P3=-53.3kPa P4=-400mmHg

----------

S=-mm L2=0.56+-0.2mm T=1.2~1.5N-m{0.12~0.15kgf-m}

----------

L2=0.56+-0.2mm P3=-53.3kPa P4=-400mmHg

----------

S=-mm L2=0.56+-0.2mm T=1.2~1.5N-m{0.12~0.15kgf-m}

0000002001 A/T PLATE ADJUSTMENT

A/T plate adjustment

1. Turn the control lever from the idle position (B) to the Full speed position (C)

2. Adjust the A/T plate (D) so that (A)(C) - (A)(B) = L3, then fix.

----------

L3=33+-0.5mm

----------

L1=95.5mm L2=109.5mm L3=33+-0.5mm T=3.5~5N-m(0.35~0.5kgf-m)

----------

L3=33+-0.5mm

----------

L1=95.5mm L2=109.5mm L3=33+-0.5mm T=3.5~5N-m(0.35~0.5kgf-m)

Information:

start by:a) remove oil panb) remove crankshaft pulley1. Remove nuts (2) and tachometer drive cover (1). 2. Remove bolts (3) and front support (4). 3. Loosen clamp (5) and disconnect hose (6) from the timing gear cover. 4. Remove clips (8) and then disconnect three lines (7). 5. Remove clamp (9) from the water sleeve.6. Install tool (A) on the water sleeve and then push water sleeve (10) into the front cover. 7. Remove two bolts (11), connector (12) and the gasket behind it. 8. Remove bolts (13), elbow (14) and the gasket behind it. 9. Remove bolt (15) and then disconnect clamp (16) that holds the oil pump sump tube. 10. Install tooling (B) in the front cover and then fasten a hoist. Remove all the bolts that hold timing gear cover to the cylinder block. Remove the cover (17) and oil pump. The weight of the timing gear cover and oil pump is 62 kg (136 lb.).

Be extra careful not to cause damage to the crankshaft front seal during removal and installation of the timing gear cover.

Install Timing Gear Cover And Oil Pump

1. Clean the contact surfaces of the cylinder block and timing gear cover. Install the timing gear cover gasket on the cylinder block. Make sure the water sleeves are installed in the timing gear cover. Put oil on the seals on the water sleeves. 2. Install tooling (A) on timing gear cover (1).3. Put the cover in position and make an alignment of the dowels and their respective holes. Install the bolts that hold cover (1) to the cylinder block. 4. Connect clamp (3) that holds the oil pump sump tube. Install bolt (2). 5. Install gasket and elbow (4) on the timing gear cover with the bolts (5) that hold it.6. Install gasket and connector (7) in the cover and install the bolts (6) that hold it. 7. Install tool (B) on water sleeve (8), then push water sleeve into the cylinder block. 8. Install clamps (9) on the water sleeve. 9. Connect three lines (10) and install the clips (11) that hold them. 10. Install hose (13) on timing gear cover and install clamp (12). 11. Put engine support (16) in position and install the bolts (17) that hold it. 12. Put tachometer cover (15) in position and install the nuts (14) that hold it. end by:a) install crankshaft pulleyb) install oil pan

Be extra careful not to cause damage to the crankshaft front seal during removal and installation of the timing gear cover.

Install Timing Gear Cover And Oil Pump

1. Clean the contact surfaces of the cylinder block and timing gear cover. Install the timing gear cover gasket on the cylinder block. Make sure the water sleeves are installed in the timing gear cover. Put oil on the seals on the water sleeves. 2. Install tooling (A) on timing gear cover (1).3. Put the cover in position and make an alignment of the dowels and their respective holes. Install the bolts that hold cover (1) to the cylinder block. 4. Connect clamp (3) that holds the oil pump sump tube. Install bolt (2). 5. Install gasket and elbow (4) on the timing gear cover with the bolts (5) that hold it.6. Install gasket and connector (7) in the cover and install the bolts (6) that hold it. 7. Install tool (B) on water sleeve (8), then push water sleeve into the cylinder block. 8. Install clamps (9) on the water sleeve. 9. Connect three lines (10) and install the clips (11) that hold them. 10. Install hose (13) on timing gear cover and install clamp (12). 11. Put engine support (16) in position and install the bolts (17) that hold it. 12. Put tachometer cover (15) in position and install the nuts (14) that hold it. end by:a) install crankshaft pulleyb) install oil pan