Information injection-pump assembly

ZEXEL

104740-1670

1047401670

ISUZU

8943105540

8943105540

Rating:

Cross reference number

ZEXEL

104740-1670

1047401670

ISUZU

8943105540

8943105540

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

52.2

51.7

52.7

Difference in delivery

mm3/st.

4

Basic

*

Remarks

Full

Full

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

22.85

21.7

24

Boost pressure

mmHg

170

160

180

Average injection quantity

mm3/st.

45.3

44.8

45.8

Difference in delivery

mm3/st.

3.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

15.6

14.1

17.1

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

42.4

38.9

45.9

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

52.2

51.2

53.2

Remarks

Full

Full

Injection timing adjustment_06

Pump speed

r/min

750

750

750

Boost pressure

kPa

22.85

21.7

24

Boost pressure

mmHg

170

160

180

Average injection quantity

mm3/st.

45.3

44.3

46.3

Remarks

CBS

CBS

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

39.7

36.2

43.2

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

15.6

14.6

16.6

Difference in delivery

mm3/st.

3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

425

425

425

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

425

425

425

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Governor adjustment_03

Pump speed

r/min

700

700

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

65

55

75

Basic

*

Speed control lever angle

Pump speed

r/min

425

425

425

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

399

270

528

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Stop lever angle_03

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

2.7

2.5

2.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

2.7

2.4

3

_03

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

4.8

4.2

5.4

_04

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

6.2

5.8

6.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

39

38.5

39.5

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

39

38

40

Timer stroke variation dT

mm

0.6

0.3

0.9

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

25

23.5

26.5

Timer stroke variation dT

mm

1.2

0.7

1.7

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

BCS stroke

mm

4

3.9

4.1

Control lever angle alpha

deg.

-10

-14

-6

Control lever angle beta

deg.

37

32

42

Test data Ex:

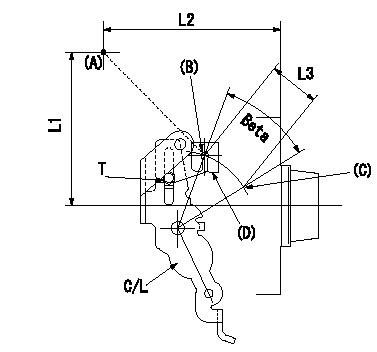

0000001801 A/T PLATE ADJUSTMENT

A/T plate adjustment

1. Turn the control lever from the idle position (B) to the Full speed position (C)

2. Adjust the A/T plate (D) so that (A)(C) - (A)(B) = L3, then fix.

----------

L3=33+-0.5mm

----------

L1=91.5mm L2=90.5mm L3=33+-0.5mm T=3.5~5N-m(0.35~0.5kgf-m)

----------

L3=33+-0.5mm

----------

L1=91.5mm L2=90.5mm L3=33+-0.5mm T=3.5~5N-m(0.35~0.5kgf-m)

Information:

1. Remove carbon seal dam (2) with pliers. Remove compression seal (1). 2. Install a new compression seal on the nozzle. Install a new carbon seal dam with tool (B).3. Make sure the bore in the cylinder head and the fuel inlet fittings are clean.4. Install new O-ring seals on adapter (3) and fuel injection nozzle (4).5. Install the fuel injection nozzle in the head. Turn and push the nozzle into its correct position. Never put lubricant on the nozzle or bore in the cylinder head. 6. Install the adapter in the head. Connect the nozzle and fuel injection line to the adapter. Tighten the nuts to a torque of 40 7 N m (30 5 lb.ft.).7. Install the spacer and clamp (5) that hold the nozzle to the cylinder head. end by:a) install rocker shaftsDisassemble Fuel Injection Nozzles (9N3979 & 1W5829)

start by:a) remove fuel injection nozzles Do not disassemble any nozzle until test has shown it is needed. Check each nozzle with tool (A) for leakage, the pressure, at which the nozzle opens, and the shape and amount of fuel (spray pattern) that comes out of the nozzle. Do not clean or make an adjustment to any nozzle that has a large (excessive) amount of return leakage. Excessive return leakage can be an indication of nozzle failures that cannot be corrected with an adjustment or cleaning and can cause engine damage. See TESTING 9N3979 & 1W5829 FUEL INJECTION NOZZLES in TESTING AND ADJUSTING.

Keep the work area and all tools extra clean. Be careful not to cause damage to the parts while the nozzles are disassembled and assembled.

1. Remove cap (1) from the fuel injection nozzle.2. Put the nozzle in tool (B). Put tool (B) and the nozzle in a vise. Do not put any part of a nozzle directly in a vise. Loosen locknut (2) while the lift adjustment screw is held. Turn the lift adjustment screw (3) counterclockwise one turn. Hold the lift adjustment screw (3) with a 5/64" hex wrench and remove the locknut (2).

If the lift adjustment screw is not turned counterclockwise one turn, the valve can be bent or the seat for the valve can be damaged when the pressure adjustment screw is turned.

3. Loosen the locknut (4) that holds the pressure adjustment screw. Use tool (D) to hold the pressure adjustment screw. 4. While the nozzle is held in one hand, tilt the nozzle and remove the pressure adjusting screw and locknut, spring, seat and valve. 5. If the valve does not slide out of the nozzle, install tool (C) and remove valve as follows: a) Push valve into nozzle with tool (C) until valve is against bottom of nozzle.b) Push down on body of tool (C) to engage collet on valve with tool (C). c) Turn nut counterclockwise and remove valve from the nozzle body. Put the parts in solvent to loosen carbon and deposits of foreign material. The body is assembled with an epoxy material and must

start by:a) remove fuel injection nozzles Do not disassemble any nozzle until test has shown it is needed. Check each nozzle with tool (A) for leakage, the pressure, at which the nozzle opens, and the shape and amount of fuel (spray pattern) that comes out of the nozzle. Do not clean or make an adjustment to any nozzle that has a large (excessive) amount of return leakage. Excessive return leakage can be an indication of nozzle failures that cannot be corrected with an adjustment or cleaning and can cause engine damage. See TESTING 9N3979 & 1W5829 FUEL INJECTION NOZZLES in TESTING AND ADJUSTING.

Keep the work area and all tools extra clean. Be careful not to cause damage to the parts while the nozzles are disassembled and assembled.

1. Remove cap (1) from the fuel injection nozzle.2. Put the nozzle in tool (B). Put tool (B) and the nozzle in a vise. Do not put any part of a nozzle directly in a vise. Loosen locknut (2) while the lift adjustment screw is held. Turn the lift adjustment screw (3) counterclockwise one turn. Hold the lift adjustment screw (3) with a 5/64" hex wrench and remove the locknut (2).

If the lift adjustment screw is not turned counterclockwise one turn, the valve can be bent or the seat for the valve can be damaged when the pressure adjustment screw is turned.

3. Loosen the locknut (4) that holds the pressure adjustment screw. Use tool (D) to hold the pressure adjustment screw. 4. While the nozzle is held in one hand, tilt the nozzle and remove the pressure adjusting screw and locknut, spring, seat and valve. 5. If the valve does not slide out of the nozzle, install tool (C) and remove valve as follows: a) Push valve into nozzle with tool (C) until valve is against bottom of nozzle.b) Push down on body of tool (C) to engage collet on valve with tool (C). c) Turn nut counterclockwise and remove valve from the nozzle body. Put the parts in solvent to loosen carbon and deposits of foreign material. The body is assembled with an epoxy material and must