Information injection-pump assembly

ZEXEL

104740-1640

1047401640

ISUZU

8944778220

8944778220

Rating:

Cross reference number

ZEXEL

104740-1640

1047401640

ISUZU

8944778220

8944778220

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

22.85

21.7

24

Boost pressure

mmHg

170

160

180

Average injection quantity

mm3/st.

45.3

44.8

45.8

Difference in delivery

mm3/st.

3.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

52.2

51.7

52.7

Difference in delivery

mm3/st.

4

Basic

*

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

15.6

14.1

17.1

Injection timing adjustment_04

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

42.35

38.8

45.9

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

52.2

51.2

53.2

Remarks

Full

Full

Injection timing adjustment_06

Pump speed

r/min

750

750

750

Boost pressure

kPa

22.85

21.7

24

Boost pressure

mmHg

170

160

180

Average injection quantity

mm3/st.

45.3

44.3

46.3

Remarks

CBS

CBS

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

39.75

36.2

43.3

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

15.6

14.6

16.6

Difference in delivery

mm3/st.

3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

3.5

Governor adjustment

Pump speed

r/min

330

330

330

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

330

330

330

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

65

55

75

Basic

*

Speed control lever angle

Pump speed

r/min

330

330

330

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

399

270

528

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Stop lever angle_04

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

2.7

2.5

2.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

2.7

2.4

3

_03

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

5.2

4.6

5.8

_04

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Timer stroke

mm

6.2

5.8

6.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

34

33.5

34.5

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

34

33

35

Timer stroke variation dT

mm

0.6

0.3

0.9

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

64

62.7

65.3

Boost pressure

mmHg

480

470

490

Average injection quantity

mm3/st.

20

18.5

21.5

Timer stroke variation dT

mm

1.2

0.7

1.7

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

BCS stroke

mm

4

3.9

4.1

Control lever angle alpha

deg.

-20.5

-24.5

-16.5

Control lever angle beta

deg.

43

38

48

Test data Ex:

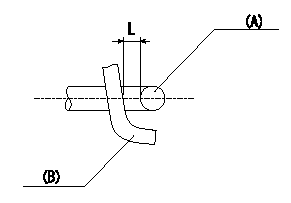

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 {P2} to the actuator and confirm that it moves through its full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

0000001901 POTENTIOMETER ADJUSTMENT

Adjusting method

N = pump speed

V = output voltage

Q = injection quantity

P = boost pressure

A = adjusting point

B = target value

Vi = applied voltage

----------

----------

N1=750r/min N2=600r/min V1=2.6V V2=2.0V V3=-V Q1=31.6+-1cm3/1,000st Q2=(23.1)cm3/1,000st Q3=-cm3/1,000st P1=0kPa P2=0mmHg Vi=10V

----------

----------

N1=750r/min N2=600r/min V1=2.6V V2=2.0V V3=-V Q1=31.6+-1cm3/1,000st Q2=(23.1)cm3/1,000st Q3=-cm3/1,000st P1=0kPa P2=0mmHg Vi=10V

Information:

Before any service work is done on the fuel system, the outer surface of the injection pump housing must be clean.

Illustrations show fuel injection pump housing and governor removed from engine. Service work can be done with it installed on engine.1. Remove air bleed lines (2). 2. Remove bolts (1), flange (3), the flange assembly and the gaskets.3. Remove the bolts and the cover. 4. Remove bolts (5), solenoid (4) and the gasket.5. Remove two bolts (7) and fuel ratio control (6).6. Remove the shutoff housing from the cover. 7. Remove the bolts, lever (10) and shaft (8).8. Remove the bolts, lever (9) and shaft (11).9. Remove seal (12) from the shutoff housing. Install Shutoff Housing

1. Put 5S1454 Sealing Compound on the outside diameter of the seal and install the seal (1) with tooling (A) in the shutoff housing with the lip toward the outside. The outer face of the seal must be 1.0 mm (.039 in.) below the surface of the housing. Remove the extra sealing compound from the housing and the seal after installation. 2. Put shaft (5) in position in housing (4).3. Install lever (6) and the bolts. 4. Install shaft (2), lever (3) and the bolts. Make an alignment of the notch in shaft (2) with lever (3). 5. Put cover (7) in position on shutoff housing assembly (8) and install the bolts.6. Put fuel ratio control (10) in position and install the bolts. 7. Install the gasket, solenoid (9) and bolts on the cover.8. Put the cover in position and install the bolts.9. Install the gasket, flange assembly, gasket, flange (11) and the bolts.10. Connect air bleed lines (12).