Information injection-pump assembly

ZEXEL

104740-1600

1047401600

ISUZU

8944696830

8944696830

Rating:

Cross reference number

ZEXEL

104740-1600

1047401600

ISUZU

8944696830

8944696830

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

50.9

50.4

51.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.5

48

51

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

50.9

49.9

51.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

42.7

41.1

44.3

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

24.9

21.9

27.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

24.9

21.9

27.9

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

70

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

70

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

451

431

471

Pressure

kgf/cm2

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

451

431

471

Pressure

kgf/cm2

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

1.7

1.5

1.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

930

830

1030

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

1.7

1.5

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

4.6

4.2

5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

5.7

5.4

6.1

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.9

28.4

29.4

Timer stroke TA

mm

1.3

1.3

1.3

Timer stroke variation dT

mm

0.4

0.2

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.9

27.9

29.9

Timer stroke variation dT

mm

0.4

0.1

0.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17

19

Timer stroke variation dT

mm

0.8

0.3

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

-2

-6

2

Control lever angle beta

deg.

38

33

43

Test data Ex:

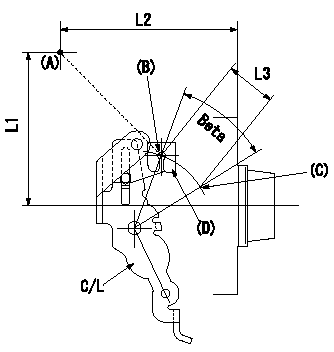

0000001801 A/T PLATE ADJUSTMENT

A/T plate adjustment

1. Turn (beta) so that the control lever (C/L) moves from the idle position (B) to the full speed position (C)

2. When angle beta is e, adjust A/T plate (D) so that wire stroke L3 is secured between (A) and (B), then fix.

----------

L3=33+-1mm e=(38+-5)deg

----------

L1=95.5mm L2=109.5mm L3=33+-1mm

----------

L3=33+-1mm e=(38+-5)deg

----------

L1=95.5mm L2=109.5mm L3=33+-1mm

Information:

2. Loosen clamp (5). 3. Remove three bolts (4) and elbow (6) from the turbocharger.4. Loosen clamp (7) on the inlet manifold hose. 5. Loosen clamp (8) and slide it on to the turbocharger. 6. Loosen bolts and nuts (9) and slide tubes (10) into the exhaust manifold flanges to get clearance for the removal of the turbocharger.7. Remove two bolts (12) and turbocharger (11). 8. Remove two O-ring seals (14).9. Remove three bolts (13) and mounting bracket (15). 10. Remove the two O-ring seals from the cylinder block.Install Turbocharger

1. Inspect all O-ring seals for wear or damage. Put a small amount of oil on the O-ring seals. 2. Put O-ring seals (1) and (3) in position.3. Install mounting bracket (2) and the bolts that hold it in place. 4. Put turbocharger (4) in position and install the bolts.5. Put tube (7) in position and install clamps (5). 6. Put 5P3931 Anti-Seize on the threads of bolts (6). Install bolts (6) and the nuts. 7. Put clamp (8) in position and tighten it.8. Put elbow (9) in position and install the bolts. 9. Tighten clamp (10). 10. Put hoses (12) in position and tighten clamps (11).

1. Inspect all O-ring seals for wear or damage. Put a small amount of oil on the O-ring seals. 2. Put O-ring seals (1) and (3) in position.3. Install mounting bracket (2) and the bolts that hold it in place. 4. Put turbocharger (4) in position and install the bolts.5. Put tube (7) in position and install clamps (5). 6. Put 5P3931 Anti-Seize on the threads of bolts (6). Install bolts (6) and the nuts. 7. Put clamp (8) in position and tighten it.8. Put elbow (9) in position and install the bolts. 9. Tighten clamp (10). 10. Put hoses (12) in position and tighten clamps (11).