Information injection-pump assembly

ZEXEL

104740-1590

1047401590

ISUZU

8944696820

8944696820

Rating:

Cross reference number

ZEXEL

104740-1590

1047401590

ISUZU

8944696820

8944696820

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

50.9

50.4

51.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.5

48

51

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

50.9

49.9

51.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

42.7

41.1

44.3

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

24.9

21.9

27.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

24.9

21.9

27.9

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.3

8.3

12.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

70

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

50

70

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

451

431

471

Pressure

kgf/cm2

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

451

431

471

Pressure

kgf/cm2

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

1.7

1.5

1.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

930

830

1030

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

1.7

1.5

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

4.6

4.2

5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

5.7

5.4

6.1

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.9

28.4

29.4

Timer stroke TA

mm

1.3

1.3

1.3

Timer stroke variation dT

mm

0.4

0.2

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.9

27.9

29.9

Timer stroke variation dT

mm

0.4

0.1

0.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

18

17

19

Timer stroke variation dT

mm

0.8

0.3

1.3

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

-2

-6

2

Control lever angle beta

deg.

42

37

47

Test data Ex:

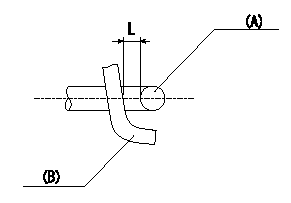

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 {P2} to the actuator and confirm that it moves through its full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

Information:

Recommended Procedure

A. Outside Leaks1. Leaks in Hoses or Connections ... Check all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps.2. Leaks in the Radiator and/or Expansion Tank ... Put pressure to the radiator and/or expansion tank with the 9S8140 Cooling System Pressurizing Pump Group and check for leaks.3. Leaks in the Heater ... Put pressure to the cooling system with the 9S8140 Cooling System pressurizing Pump Group and check the heater for leaks.4. Leaks in the Water Pump ... Check the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, repair or install a new water pump.5. Cylinder Head Gasket Leakage ... Look for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.B. Coolant Leaks at the Overflow Tube6. Bad Pressure Cap or Relief Valve ... Check the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap or relief valve with the 9S8140 Cooling System Pressurizing Pump Group.7. Engine Runs Too Hot ... If coolant temperature is too high, pressure will be high enough to move the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Above Normal Heating" in COOLING SYSTEM Chart.8. Expansion Tank Too Small or Installed Wrong ... The expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly, and the size is according to the recommendations of the Truck Manufacturer.9. Cylinder Head Gasket Leakage, or Crack(s) in Cylinder Head or Cylinder Block ... Remove the radiator cap and with the engine running look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. With the engine not running, check each cylinder with the cylinder leakage tester. Special Instruction, Form No. GMG00694 gives the test procedure. If you see air bubbles in the coolant during this test, there is a leak of combustion gas into the cooling system. Remove the cylinder heads from the engine. Check cylinder heads, cylinder walls and head gasket surface of the cylinder block for cracks. When installing heads, use new head gasket.C. Inside Leakage10. Cylinder Head Gasket Leakage ... If the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.11. Crack(s) in Cylinder Head ... Crack(s) in the upper surface of the cylinder head, or an area between a water passage and an opening into the crankcase, can allow

A. Outside Leaks1. Leaks in Hoses or Connections ... Check all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps.2. Leaks in the Radiator and/or Expansion Tank ... Put pressure to the radiator and/or expansion tank with the 9S8140 Cooling System Pressurizing Pump Group and check for leaks.3. Leaks in the Heater ... Put pressure to the cooling system with the 9S8140 Cooling System pressurizing Pump Group and check the heater for leaks.4. Leaks in the Water Pump ... Check the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, repair or install a new water pump.5. Cylinder Head Gasket Leakage ... Look for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.B. Coolant Leaks at the Overflow Tube6. Bad Pressure Cap or Relief Valve ... Check the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap or relief valve with the 9S8140 Cooling System Pressurizing Pump Group.7. Engine Runs Too Hot ... If coolant temperature is too high, pressure will be high enough to move the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Above Normal Heating" in COOLING SYSTEM Chart.8. Expansion Tank Too Small or Installed Wrong ... The expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly, and the size is according to the recommendations of the Truck Manufacturer.9. Cylinder Head Gasket Leakage, or Crack(s) in Cylinder Head or Cylinder Block ... Remove the radiator cap and with the engine running look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. With the engine not running, check each cylinder with the cylinder leakage tester. Special Instruction, Form No. GMG00694 gives the test procedure. If you see air bubbles in the coolant during this test, there is a leak of combustion gas into the cooling system. Remove the cylinder heads from the engine. Check cylinder heads, cylinder walls and head gasket surface of the cylinder block for cracks. When installing heads, use new head gasket.C. Inside Leakage10. Cylinder Head Gasket Leakage ... If the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.11. Crack(s) in Cylinder Head ... Crack(s) in the upper surface of the cylinder head, or an area between a water passage and an opening into the crankcase, can allow