Information injection-pump assembly

ZEXEL

104740-1421

1047401421

ISUZU

8944542981

8944542981

Rating:

Cross reference number

ZEXEL

104740-1421

1047401421

ISUZU

8944542981

8944542981

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

43.5

43

44

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

47.8

47.3

48.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

43.5

42.5

44.5

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

47.8

46.8

48.8

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

42.9

40.9

44.9

Oil temperature

degC

52

50

54

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

41.4

39.4

43.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

55

53

57

Injection quantity adjustment_02

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

7

Oil temperature

degC

55

53

57

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

686

657

715

Pressure

kgf/cm2

7

6.7

7.3

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

860

760

960

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

6.8

6.5

7.1

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

9

8.7

9.4

Oil temperature

degC

52

50

54

_06

Pump speed

r/min

0

0

0

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.5

2.3

2.7

Oil temperature

degC

48

46

50

Remarks

C.S.D. advance angle

C.S.D. advance angle

_07

Pump speed

r/min

600

500

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

C.D.. cancel speed.

C.D.. cancel speed.

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.4

1.3

1.5

BCS stroke

mm

1.8

1.6

2

Control lever angle alpha

deg.

17

13

21

Control lever angle beta

deg.

42

37

47

Test data Ex:

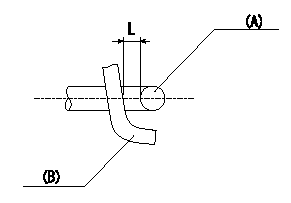

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 {P2} to the actuator and confirm that it moves through its full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

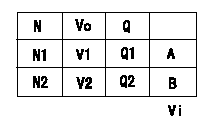

0000001901 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment (oval)

N:Pump speed

Vo:Output voltage

Q:Injection quantity

A:Adjusting point

B:Target value

Vi:Applied voltage

----------

----------

N1=700(r/min) N2=500(r/min) V1=4.10(V) V2=3.33(V) Q1=22.9+-1(mm3/st) Q2=(18.6(mm3/st)) Vi=10(V)

----------

----------

N1=700(r/min) N2=500(r/min) V1=4.10(V) V2=3.33(V) Q1=22.9+-1(mm3/st) Q2=(18.6(mm3/st)) Vi=10(V)

Information:

1. Disconnect the fuel ratio control sensing line (1). Remove the sensing line clamp bolt (2).2. Disconnect the air compressor water return line (6). 3. Remove the cylinder head air inlet line (3).4. Remove the retaining bolts (4) and the fan drive mounting bracket (5).5. Remove the cylinder head retaining bolts. Attach a hoist and remove the cylinder head assembly - weight 164 lbs. (74,4 kg).Install Cylinder Head

1. Thoroughly clean the sealing surfaces of the cylinder head and cylinder block. Position a new head gasket on the engine and install the cylinder head.2. Install the push rods and rocker shaft assembly.3. Coat the threads of the cylinder head retaining bolts with 4S9416 Anti-Seize Compound. Install bolts and washers, and tighten them in the following sequence: 1 - Tighten all numbered bolts in numerical order to 115 lb. ft. (15,9 mkg).2 - Retighten all numbered bolts in numerical order to 175 5 lb. ft. (24,2 0,7 mkg).3 - Finally, retighten all numbered bolts (hand torque only) in numerical order to 175 5 lb. ft. (24,2 0,7 mkg).4 - Tighten all lettered bolts in alphabetical order to 22 lb. ft. (3,0 mkg).5 - Retighten all lettered bolts in alphabetical order to 32 5 lb. ft. (4,4 0,7 mkg).6 - Finally, retighten all lettered bolts (hand torque only) in alphabetical order to 32 5 lb. ft. (4,4 0,7 mkg).4. Adjust the inlet and exhaust valve clearance as covered in INSTALL ROCKER SHAFT ASSEMBLY AND PUSH RODS.5. Connect the air compressor water return line.6. Connect the fuel ratio control sensing line and install the sensing line clamp bolt.7. Install the fan drive mounting bracket and retaining bolts.concluding steps: a) install water temperature regulatorb) install valve coverc) install precombustion chambersd) install exhaust manifold

1. Thoroughly clean the sealing surfaces of the cylinder head and cylinder block. Position a new head gasket on the engine and install the cylinder head.2. Install the push rods and rocker shaft assembly.3. Coat the threads of the cylinder head retaining bolts with 4S9416 Anti-Seize Compound. Install bolts and washers, and tighten them in the following sequence: 1 - Tighten all numbered bolts in numerical order to 115 lb. ft. (15,9 mkg).2 - Retighten all numbered bolts in numerical order to 175 5 lb. ft. (24,2 0,7 mkg).3 - Finally, retighten all numbered bolts (hand torque only) in numerical order to 175 5 lb. ft. (24,2 0,7 mkg).4 - Tighten all lettered bolts in alphabetical order to 22 lb. ft. (3,0 mkg).5 - Retighten all lettered bolts in alphabetical order to 32 5 lb. ft. (4,4 0,7 mkg).6 - Finally, retighten all lettered bolts (hand torque only) in alphabetical order to 32 5 lb. ft. (4,4 0,7 mkg).4. Adjust the inlet and exhaust valve clearance as covered in INSTALL ROCKER SHAFT ASSEMBLY AND PUSH RODS.5. Connect the air compressor water return line.6. Connect the fuel ratio control sensing line and install the sensing line clamp bolt.7. Install the fan drive mounting bracket and retaining bolts.concluding steps: a) install water temperature regulatorb) install valve coverc) install precombustion chambersd) install exhaust manifold