Information injection-pump assembly

ZEXEL

104740-1410

1047401410

ISUZU

8944542970

8944542970

Rating:

Cross reference number

ZEXEL

104740-1410

1047401410

ISUZU

8944542970

8944542970

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

46.8

46.3

47.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

49.4

48.9

49.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

46.8

45.8

47.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

49.5

47.5

51.5

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

49.4

48.4

50.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

41.8

39.8

43.8

Oil temperature

degC

52

50

54

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

40.7

38.7

42.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

7

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

471

451

491

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

677

648

706

Pressure

kgf/cm2

6.9

6.6

7.2

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

860

760

960

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

6.8

6.5

7.1

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

9

8.7

9.4

Oil temperature

degC

52

50

54

_06

Pump speed

r/min

0

0

0

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.5

2.3

2.7

Oil temperature

degC

48

46

50

Remarks

C.S.D. advance angle

C.S.D. advance angle

_07

Pump speed

r/min

600

500

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

C.D.. cancel speed.

C.D.. cancel speed.

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

BCS stroke

mm

2.2

2

2.4

Control lever angle alpha

deg.

17

13

21

Control lever angle beta

deg.

42

37

47

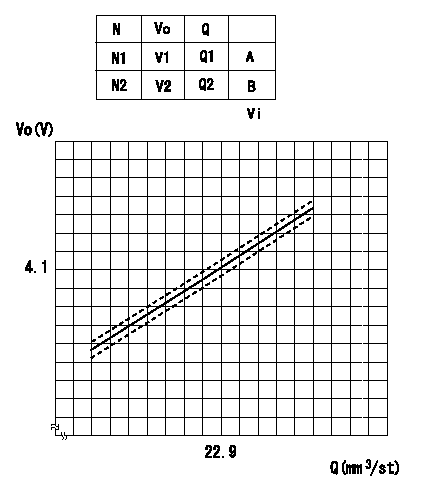

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment (oval)

At pump speed N1, measure the injection quantity when the control lever is moved a from the idle position (lever, stopper gap L). Then install the potentiometer.

N:Pump speed

Vo:Output voltage

Q:Injection quantity

A:Adjusting point

B:Checking point

Vi:Applied voltage

----------

N1=700(r/min) a=14.5(deg) L=4.8(mm) Vi=10(V)

----------

N1=700(r/min) N2=500(r/min) V1=4.10(V) V2=3.33(V) Q1=22.9+-1(mm3/st) Q2=(18.6(mm3/st)) Vi=10(V)

----------

N1=700(r/min) a=14.5(deg) L=4.8(mm) Vi=10(V)

----------

N1=700(r/min) N2=500(r/min) V1=4.10(V) V2=3.33(V) Q1=22.9+-1(mm3/st) Q2=(18.6(mm3/st)) Vi=10(V)

Information:

preparatory step: a) separate governor from fuel injection pump housing. 1. Remove the fuel injection pump as follows: a) Remove the protective cap and the felt washer (1). b) Install wrench (A) and remove retaining bushing (2) from housing.c) Remove the seal (3). d) Install extractor (B).e) Lift the fuel injection pump out of the housing.f) Remove the spacer (4). Keep the spacers (4) and pumps together, and identified as to their location in the fuel injection pump housing.2. Disassemble the fuel injection pumps as follows: a) Remove the bonnet (5), ring (6), spring (7), and check valve (8) from the barrel (9).b) Remove the plunger assembly (10), washer (11), and spring (12) from the barrel (9).

While disassembling and assembling fuel injection pump, exercise considerable care to prevent damage to plunger surfaces. The barrel and plunger assemblies are matched, and the individual parts are not interchangeable with other barrels or plunger assemblies.

3. Remove the rack (13).4. Remove the lifters (14). Keep the lifters identified and together with their respective pumps and spacers. 5. Remove the camshaft retaining plate (15), bolt and lock. 6. Remove the spring (16) and the gear assembly (17) from the camshaft. 7. Remove the camshaft (19). 8. Using tool (C), remove the camshaft bearings from the fuel injection pump housing.9. Remove the two rack bearings (18) from the fuel injection pump housing.Assemble Fuel Injection Pump Housing

1. Using tool group (C), install the camshaft bearings in the fuel injection pump housing. Install the bearing in governor end of housing so the oil hole in bearing is aligned with oil hole in housing. Install the camshaft bearings flush with outer ends of fuel injection pump housing. 2. Using tool (D), install the two rack bearings in the fuel injection pump housing. Install the bearing in governor end of housing so it will be recessed .195 .005 in. (4,953 0,127 mm) from face of housing. Install the rack bearing in accessory drive end of housing so it will be flush with face of fuel injection pump housing. 3. Lubricate the camshaft with clean SAE 30 engine oil. Install the camshaft in fuel injection pump housing. 4. Postion the governor drive gear (1) and spring (2) on the camshaft. Install the camshaft retaining plate (3), bolt, and lock. 5. Install the lifters (4) in their respective positions in housing. Lubricate the rack generously with clean SAE 30 engine oil. Install the rack (5) into fuel injection pump housing with the slot in rack toward the governor end of housing.6. Install the spacers in their respective positions in housing. If new lifters and pumps are to be installed, it will be necessary to set the fuel pump timing dimension. See FUEL INJECTION PUMP TIMING DIMENSION SETTING-OFF ENGINE in TESTING AND ADJUSTING.7. Assemble the fuel injection pumps as follows: a) Lubricate all parts generously with clean fuel oil.b) Install the spring, washer, and plunger in the barrel.c) Install the spring, check valve, bonnet, and ring on the barrel.

Do

While disassembling and assembling fuel injection pump, exercise considerable care to prevent damage to plunger surfaces. The barrel and plunger assemblies are matched, and the individual parts are not interchangeable with other barrels or plunger assemblies.

3. Remove the rack (13).4. Remove the lifters (14). Keep the lifters identified and together with their respective pumps and spacers. 5. Remove the camshaft retaining plate (15), bolt and lock. 6. Remove the spring (16) and the gear assembly (17) from the camshaft. 7. Remove the camshaft (19). 8. Using tool (C), remove the camshaft bearings from the fuel injection pump housing.9. Remove the two rack bearings (18) from the fuel injection pump housing.Assemble Fuel Injection Pump Housing

1. Using tool group (C), install the camshaft bearings in the fuel injection pump housing. Install the bearing in governor end of housing so the oil hole in bearing is aligned with oil hole in housing. Install the camshaft bearings flush with outer ends of fuel injection pump housing. 2. Using tool (D), install the two rack bearings in the fuel injection pump housing. Install the bearing in governor end of housing so it will be recessed .195 .005 in. (4,953 0,127 mm) from face of housing. Install the rack bearing in accessory drive end of housing so it will be flush with face of fuel injection pump housing. 3. Lubricate the camshaft with clean SAE 30 engine oil. Install the camshaft in fuel injection pump housing. 4. Postion the governor drive gear (1) and spring (2) on the camshaft. Install the camshaft retaining plate (3), bolt, and lock. 5. Install the lifters (4) in their respective positions in housing. Lubricate the rack generously with clean SAE 30 engine oil. Install the rack (5) into fuel injection pump housing with the slot in rack toward the governor end of housing.6. Install the spacers in their respective positions in housing. If new lifters and pumps are to be installed, it will be necessary to set the fuel pump timing dimension. See FUEL INJECTION PUMP TIMING DIMENSION SETTING-OFF ENGINE in TESTING AND ADJUSTING.7. Assemble the fuel injection pumps as follows: a) Lubricate all parts generously with clean fuel oil.b) Install the spring, washer, and plunger in the barrel.c) Install the spring, check valve, bonnet, and ring on the barrel.

Do