Information injection-pump assembly

ZEXEL

104740-1320

1047401320

ISUZU

8944240821

8944240821

Rating:

Cross reference number

ZEXEL

104740-1320

1047401320

ISUZU

8944240821

8944240821

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

46.3

45.8

46.8

Difference in delivery

mm3/st.

3.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

48.3

47.8

48.8

Difference in delivery

mm3/st.

4

Basic

*

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

46.3

45.3

47.3

Remarks

CBS

CBS

Injection timing adjustment_04

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

49.3

46.8

51.8

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

37.3

34.8

39.8

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

48.3

47.3

49.3

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

39.1

36.6

41.6

Injection timing adjustment_08

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.9

19.4

26.4

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.9

19.9

25.9

Difference in delivery

mm3/st.

7

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

79.95

78.6

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

7

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Governor adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Basic

*

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

399

270

528

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Basic

*

Stop lever angle_02

Pump speed

r/min

250

250

250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

206

177

235

Pressure

kgf/cm2

2.1

1.8

2.4

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

470.5

451

490

Pressure

kgf/cm2

4.8

4.6

5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3

2.8

3.2

Basic

*

_02

Pump speed

r/min

875

775

975

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

0.5

0.5

0.5

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

3

2.7

3.3

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

6

5.5

6.5

_05

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

9

8.6

9.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

BCS stroke

mm

2.9

2.8

3

Control lever angle alpha

deg.

17

13

21

Control lever angle beta

deg.

42

37

47

Test data Ex:

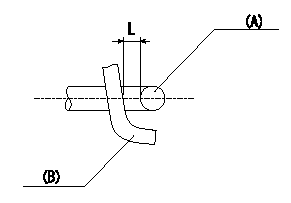

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 {P2} to the actuator and confirm that it moves through its full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa P2=-400mmHg

----------

L=1+1mm

Information:

Crankshaft Gear Removal

Remove the gear using an 8B7548 Push Puller, 8B7551 Bearing Pulling Attachment, 8B7561 Step Plate, and 8H684 Ratchet Box Wrench.

PULLING CRANKSHAFT GEARThe 1P820 Hydraulic Puller Group can also be used to pull gear from crankshaft. Tools required are 1P820 Hydraulic Puller Group, 8B7551 Bearing Pulling Attachment, 8B7549 Puller legs (two), 8B7561 Step Plate, 3H465 Plate (four), 1B4207 Nut (two), and 9S5800 Pump Group.

USING HYDRAULIC PULLERCrankshaft Gear Installation

1. Install the key in keyway of crankshaft. Remove all burrs from key and keyway inside of crankshaft gear.2. Heat gear to 500° F. (260° C) maximum.3. Install gear on crankshaft with timing mark on gear facing front of crankshaft.Crankshaft Wear Sleeve Removal

REMOVING WEAR SLEEVEUse the 8S7164 Wear Sleeve Puller Group to remove the wear sleeve.Crankshaft Wear Sleeve Installation

WEAR SLEEVE INSTALLATION TOOLS

1. 5P290 Pilot. 2. 5P286 Ring. 3. 9S8858 Nut. 4. 1P5515 Bolts. 5. 9S8864 Pusher Plate.To install the wear sleeve, use the following procedure:1. Install 5P290 Pilot (1) on the end of the crankshaft. Install 1P5515 Bolts (4) and tighten just enough to hold pilot (1) yet allow some side movement. Put the wear sleeve on pilot (1) with the chamfer toward the rear of the engine. Push the wear sleeve on the crankshaft to put pilot (1) in the center, then tighten bolts (4).2. Put 5P286 Ring (2) on 9S8864 Pusher Plate (5) and place this assembly on the stud of pilot (1). Install 9S8858 Nut (3) and tighten nut to push wear sleeve on to the crankshaft.Crankshaft Rear Oil Seal Removal

Use the 1P3075 Puller Group to remove the crankshaft rear seal.

REMOVING REAR OIL SEAL (Typical Example)Crankshaft Rear Oil Seal Installation

REAR OIL SEAL INSTALLATION TOOLS

1. 5P290 Pilot. 2. 1P5515 Bolts. 3. 5P285 Ring. 4. 9S8858 Nut. 5. 5P288 Ring. 6. 9S8864 Pusher Plate.To install the crankshaft rear oil seal, use the following procedure:1. Install 5P290 Pilot (1) on the crankshaft with 1P5515 Bolts (2). Install 5P288 Ring (5) on pilot (1).2. Put 7F2770 Cement on the outer diameter of the seal metal shell. Put engine oil on the lip of the seal. Install the seal on the pilot with the lip of the seal toward the front of the engine.3. Install 9S8864 Pusher Plate (6) and 5P285 Ring (3) over pilot (1). Install 9S8858 Nut (4). Tighten nut (4) until ring (5) makes contact with the flywheel housing. To prevent possible oil leakage, install a new wear sleeve each time the rear oil seal is replaced.Crankshaft Front Oil Seal (1100, 3100, and 3208 Engines 79V1-79V1407)

The crankshaft front oil seal can be removed with the timing gear cover on or off the engine. To install the seal to the proper depth, the timing gear cover must be on the engine.A new timing gear cover permits the crankshaft front oil seal to be installed to two depths.Use the 9S6030 Installation Group which includes the 8S2276 Installer and 9S6012 Spacer to install the seal. To install seal to the original depth, use only the 8S2276 Installer. To obtain an additional wear

Remove the gear using an 8B7548 Push Puller, 8B7551 Bearing Pulling Attachment, 8B7561 Step Plate, and 8H684 Ratchet Box Wrench.

PULLING CRANKSHAFT GEARThe 1P820 Hydraulic Puller Group can also be used to pull gear from crankshaft. Tools required are 1P820 Hydraulic Puller Group, 8B7551 Bearing Pulling Attachment, 8B7549 Puller legs (two), 8B7561 Step Plate, 3H465 Plate (four), 1B4207 Nut (two), and 9S5800 Pump Group.

USING HYDRAULIC PULLERCrankshaft Gear Installation

1. Install the key in keyway of crankshaft. Remove all burrs from key and keyway inside of crankshaft gear.2. Heat gear to 500° F. (260° C) maximum.3. Install gear on crankshaft with timing mark on gear facing front of crankshaft.Crankshaft Wear Sleeve Removal

REMOVING WEAR SLEEVEUse the 8S7164 Wear Sleeve Puller Group to remove the wear sleeve.Crankshaft Wear Sleeve Installation

WEAR SLEEVE INSTALLATION TOOLS

1. 5P290 Pilot. 2. 5P286 Ring. 3. 9S8858 Nut. 4. 1P5515 Bolts. 5. 9S8864 Pusher Plate.To install the wear sleeve, use the following procedure:1. Install 5P290 Pilot (1) on the end of the crankshaft. Install 1P5515 Bolts (4) and tighten just enough to hold pilot (1) yet allow some side movement. Put the wear sleeve on pilot (1) with the chamfer toward the rear of the engine. Push the wear sleeve on the crankshaft to put pilot (1) in the center, then tighten bolts (4).2. Put 5P286 Ring (2) on 9S8864 Pusher Plate (5) and place this assembly on the stud of pilot (1). Install 9S8858 Nut (3) and tighten nut to push wear sleeve on to the crankshaft.Crankshaft Rear Oil Seal Removal

Use the 1P3075 Puller Group to remove the crankshaft rear seal.

REMOVING REAR OIL SEAL (Typical Example)Crankshaft Rear Oil Seal Installation

REAR OIL SEAL INSTALLATION TOOLS

1. 5P290 Pilot. 2. 1P5515 Bolts. 3. 5P285 Ring. 4. 9S8858 Nut. 5. 5P288 Ring. 6. 9S8864 Pusher Plate.To install the crankshaft rear oil seal, use the following procedure:1. Install 5P290 Pilot (1) on the crankshaft with 1P5515 Bolts (2). Install 5P288 Ring (5) on pilot (1).2. Put 7F2770 Cement on the outer diameter of the seal metal shell. Put engine oil on the lip of the seal. Install the seal on the pilot with the lip of the seal toward the front of the engine.3. Install 9S8864 Pusher Plate (6) and 5P285 Ring (3) over pilot (1). Install 9S8858 Nut (4). Tighten nut (4) until ring (5) makes contact with the flywheel housing. To prevent possible oil leakage, install a new wear sleeve each time the rear oil seal is replaced.Crankshaft Front Oil Seal (1100, 3100, and 3208 Engines 79V1-79V1407)

The crankshaft front oil seal can be removed with the timing gear cover on or off the engine. To install the seal to the proper depth, the timing gear cover must be on the engine.A new timing gear cover permits the crankshaft front oil seal to be installed to two depths.Use the 9S6030 Installation Group which includes the 8S2276 Installer and 9S6012 Spacer to install the seal. To install seal to the original depth, use only the 8S2276 Installer. To obtain an additional wear