Information injection-pump assembly

ZEXEL

104740-1190

1047401190

ISUZU

8941782080

8941782080

Rating:

Cross reference number

ZEXEL

104740-1190

1047401190

ISUZU

8941782080

8941782080

Zexel num

Bosch num

Firm num

Name

104740-1190

8941782080 ISUZU

INJECTION-PUMP ASSEMBLY

4FC1-J *

4FC1-J *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

37.3

36

38.6

Boost pressure

mmHg

280

270

290

Average injection quantity

mm3/st.

47.5

47

48

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

51.3

50.8

51.8

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

550

550

550

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

37.4

35.4

39.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Boost pressure

kPa

37.3

36

38.6

Boost pressure

mmHg

280

270

290

Average injection quantity

mm3/st.

47.5

46.5

48.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

51.3

50.3

52.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

39.7

37.7

41.7

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

45.7

43.7

47.7

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

17.5

16.5

18.5

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

60

58.7

61.3

Boost pressure

mmHg

450

440

460

Average injection quantity

mm3/st.

17.5

14.5

20.5

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.2

10.2

14.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.2

10.2

14.2

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

441

421

461

Pressure

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

441

412

470

Pressure

kgf/cm2

4.5

4.2

4.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

598

569

627

Pressure

kgf/cm2

6.1

5.8

6.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.6

2.4

2.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

840

740

940

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.6

2.4

2.8

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

5.2

4.8

5.6

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

7.8

7.5

8.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

30

29

31

Timer stroke TA

mm

1.6

1.6

1.6

Timer stroke variation dT

mm

1

0.8

1.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

30

29

31

Timer stroke variation dT

mm

1

0.6

1.4

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25

24

26

Timer stroke variation dT

mm

1.55

1.15

1.95

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.3

1.2

1.4

BCS stroke

mm

3.5

3.3

3.7

Control lever angle alpha

deg.

23

19

27

Control lever angle beta

deg.

45

40

50

Test data Ex:

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

With the control lever 'a' from the idle position (idle stopper lever clearance L), adjust the position of the microswitch and fix it in the position where it goes OFF.

After adjustment, the microswitch must not turn OFF at lever position between idle and a.

Also, the microswitch lever must not contact the stopper.

----------

a=26+-1deg L=8.5+-0.2mm

----------

----------

a=26+-1deg L=8.5+-0.2mm

----------

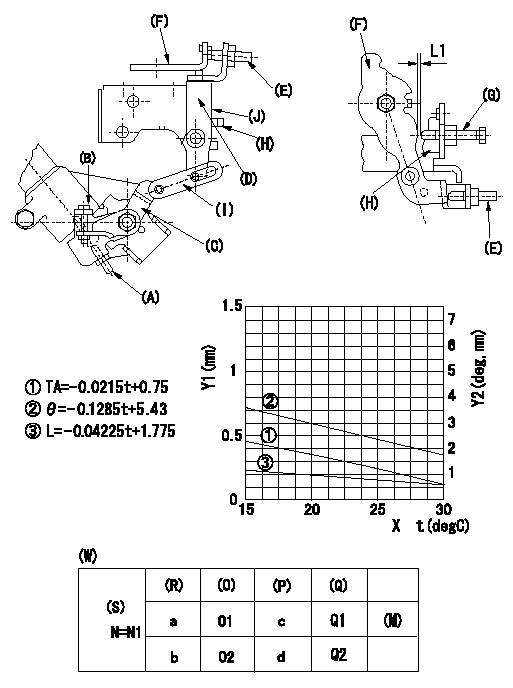

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the timer stroke

Adjust screw (A) so that the timer stroke is the value determined from the graph.

2. Adjustment of the position of the intermediate lever.

(1)Insert a shim L1 between the control lever (F) and the idle set screw (G).

(2)Set intermediate lever (D) adjusting screw (E) so that adjusting screw (E) contacts control lever, and so that when intermediate lever is at right angles to pump center, intermediate lever and idle stopper bracket (H) overlap at position (J).

3. W-CSD adjustment

Insert a shim L1+-0.05 between the control lever (F) and the idle set screw (G).

Use adjusting screw (B) to fix the CSD lever (C) in the position where it operates the intermediate lever (D) via the rod (I).

X:Temperature t (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever position at theta L (deg, mm)

(W) Cold advancer

(R) Cooling water temperature (deg C)

(S) Cooling water temperature: increase direction

(O) Timer piston stroke (mm)

(P) Lever position (deg)

(Q) lever position (mm)

(M) standard point

N:Pump speed

----------

L1=0.93+-0.05mm

----------

N1=500r/min a=20degC b=-20degC c=2.9+-1deg d=8+-3deg O1=0.3+-0.4mm O2=1.2+-0.6mm Q1=0.93+-0.3mm Q2=2.62+-1mm

----------

L1=0.93+-0.05mm

----------

N1=500r/min a=20degC b=-20degC c=2.9+-1deg d=8+-3deg O1=0.3+-0.4mm O2=1.2+-0.6mm Q1=0.93+-0.3mm Q2=2.62+-1mm

Information:

TIMING PIN HOLE PLUG (Typical Example)

1. Plug.2. Rotate the crankshaft CLOCKWISE (as viewed from front of engine) until the timing pin drops into the timing slot in the fuel injection pump camshaft.3. Disconnect wire (2) from fuel shut off solenoid.4. Remove the tachometer drive adapter housing (3).

WIRE AND HOUSING (Typical Example)

2. Wire. 3. Tachometer drive adapter housing.5. Use ratchet (4) and socket (5) to remove the tachometer drive adapter shaft.

REMOVING SHAFT

4. 8H8572 Ratchet. 5. 9S5031 Deep Well Socket.6. Using puller group (6), thread the 9S8528 Bolt Assembly into the camshaft. Do not force the bolt assembly. It should thread easily. Install the 9S8527 Bolt by threading it into the gear carrier or adapter. Then tighten the 9S8527 Bolt with a wrench until the gear carrier or adapter "pops" loose. Remove the 9S8520 Puller Group.

LOOSENING CAMSHAFT DRIVE GEAR

6. 9S8520 Puller Group.7. Remove the plug from the timing hole (8) in the front cover and insert bolt (7). The cover retaining bolt from hole (9) may be used.8. Rotate crankshaft CLOCKWISE (as viewed from front of engine) until bolt (7) threads into the timing gear and is centered in timing hole (8). With timing pin in slot in fuel pump camshaft and the bolt (7) through the front cover and threaded into the timing gear, the fuel injection pump camshaft is timed to the engine.

INSTALLING BOLT

7. 1D4539 Bolt [5/16 in. - 18 NC, 2.5 in. (63.5 mm) long]. 8. Timing hole. 9. Hole.9. Remove the fuel injection pump housing retaining bolts (10).

RETAINING BOLTS (Typical Example)

10. Retaining bolts (three).

REMOVING HOUSING (Typical Example)10. Attach a hoist and remove the fuel injection pump housing and governor as a unit, the weight is approx. 55 lbs. (23 kg).Install Fuel Injection Pump Housing and Governor

1. Attach a hoist and install the fuel injection pump housing and governor as a unit. Install the fuel injection pump housing retaining bolts.2. Install the tachometer drive adapter shaft and tighten shaft retaining nut to 32 2 lb. ft. (4.4 0.3 mkg).3. To check timing remove the timing pin and the bolt. Rotate the crankshaft two revolutions CLOCKWISE (as viewed from front of engine) and install the timing pin and bolt back in place. If the timing pin or bolt can not be installed, the fuel injection pump camshaft must be retimed.4. Remove the bolt (7) from the timing gear and install in hole (9). Install the plug into timing hole (8).5. Remove the timing pin from the timing slot in the fuel injection pump camshaft and install the plug in the timing hole.6. Install the tachometer drive adapter housing. Connect the wire to the fuel shut off solenoid.

Have questions with 104740-1190?

Group cross 104740-1190 ZEXEL

Isuzu

Isuzu

Isuzu

104740-1190

8941782080

INJECTION-PUMP ASSEMBLY

4FC1-J

4FC1-J