Information injection-pump assembly

ZEXEL

104740-1100

1047401100

ISUZU

8941323760

8941323760

Rating:

Cross reference number

ZEXEL

104740-1100

1047401100

ISUZU

8941323760

8941323760

Zexel num

Bosch num

Firm num

Name

104740-1100

8941323760 ISUZU

INJECTION-PUMP ASSEMBLY

C223T * K

C223T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

43.4

42.9

43.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

48

47.5

48.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

43.4

42.4

44.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

49

47

51

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

48

47

49

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

2175

2175

2175

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

38.7

36.7

40.7

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.8

19.8

25.8

Difference in delivery

mm3/st.

7

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

7

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

11.3

9.3

13.3

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

60

60

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Overflow quantity

cm3/min

375

245

505

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

402

382

422

Pressure

kgf/cm2

4.1

3.9

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

402

382

422

Pressure

kgf/cm2

4.1

3.9

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

530

501

559

Pressure

kgf/cm2

5.4

5.1

5.7

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure

kPa

628

599

657

Pressure

kgf/cm2

6.4

6.1

6.7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.1

1.9

2.3

Basic

*

Oil temperature

degC

50

30

70

_02

Pump speed

r/min

770

670

870

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

30

70

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.1

1.9

2.3

Basic

*

Oil temperature

degC

50

30

70

_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

5.5

5.1

5.9

Oil temperature

degC

50

30

70

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

9

8.7

9.4

Oil temperature

degC

50

30

70

_06

Pump speed

r/min

0

0

0

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke

mm

2.9

2.7

3.1

Oil temperature

degC

50

30

70

Remarks

C.S.D. advance angle

C.S.D. advance angle

_07

Pump speed

r/min

600

500

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

30

70

Remarks

C.D.. cancel speed.

C.D.. cancel speed.

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

BCS stroke

mm

3.5

3.3

3.7

Control lever angle alpha

deg.

17

13

21

Control lever angle beta

deg.

42

37

47

Test data Ex:

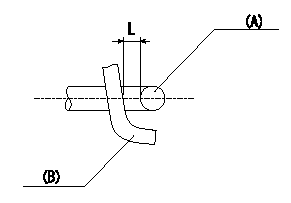

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain L1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

(A) actuator shaft

(B) Control lever

----------

L=1+1mm P1=-53.3kPa(-400mmHg)

----------

L=1+1mm

----------

L=1+1mm P1=-53.3kPa(-400mmHg)

----------

L=1+1mm

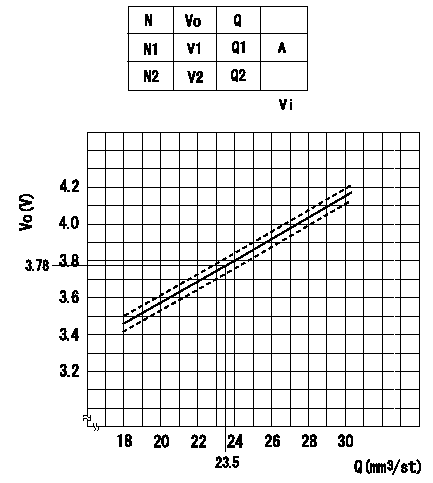

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Measure the injection quantity at pump speed N1 and control lever position a (lever, stopper clearance corresponding to L1). Install the potentiometer in accordance with the graph.

N:Pump speed

Vo:Output voltage

Q:Injection quantity

A:Adjusting point

Vi:Voltage

----------

N1=1100r/min a=20deg L1=6.6mm Vi=10V

----------

N1=1100r/min N2=800r/min V1=3.78+-0.03V V2=3.11+-0.03V Q1=23.5+-1mm3/st Q2=(25.0mm3/st) Vi=10V

----------

N1=1100r/min a=20deg L1=6.6mm Vi=10V

----------

N1=1100r/min N2=800r/min V1=3.78+-0.03V V2=3.11+-0.03V Q1=23.5+-1mm3/st Q2=(25.0mm3/st) Vi=10V

Information:

Recommended Procedure A. MISFIRING AND RUNNING ROUGHSee the chart, Misfiring and Running Rough. B. PROBLEM WITH VEHICLE or VEHICLE OPERATIONSee the chart, Problem With Vehicle or Vehicle Operation. C. LOW ENGINE RPM1. Governor Linkage Disconnect the governor linkage at the lever on the governor. Move the governor lever by hand until the linkage inside the governor is against the high idle stop. With the accelerator pedal all the way down, adjust the linkage so that the inside linkage is against the high idle stop. Some trucks are equipped with linkage which has spring force and some are equipped with a governor lever of the break over type. On engines with either of these, adjust the governor linkage .250 in. (6,35 mm) longer than necessary for the inside linkage to be against the high idle stop, this will keep tension on the spring at all times. For trucks with tilt cabs, do not make this check with the cab tilted.2. Governor High Idle Adjustment If the governor linkage moves the governor lever to the fully open position, check the high idle rpm with a good tachometer. If the high idle rpm is too low, turn the high idle adjustment screw counterclockwise until high idle rpm is correct. See the RACK SETTING INFORMATION for the correct high idle rpm. If high idle rpm can not be made correct with the high idle adjustment screw, there is a problem inside the governor. Disassemble the governor and check for damage to parts or the wrong parts installed in the governor. D. NOT ENOUGH AIR3. Inlet Restriction Air inlet restriction will cause low power and too much smoke when under load. Check for a restriction with a water manometer or a vacuum gauge (which measures in inches of water). Connect the gauge to the engine air inlet between the air cleaner and the engine. With gauge installed, run engine at full load rpm and check the restriction. Maximum restriction of the air inlet is 30 inches (762 mm) of water. If the indication is higher than the maximum permissible restriction, remove dirt from the filter element or install a new filter element and check the restriction again. If the indication is still too high, there must be a restriction in the inlet piping.4. Exhaust Restriction Make a visual inspection of the exhaust system and look for damage to piping or for a bad muffler. If no damage is found, you can also check the system by removing the exhaust pipes from the exhaust manifolds. With the exhaust pipes removed, start and run the engine to see if the problem is corrected. E. LOW QUALITY FUEL5. Water in Fuel Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from tank until it is free of water. Install a new fuel filter and fill the fuel tank with clean fuel. "Prime" (remove the air and/or low quality fuel

Have questions with 104740-1100?

Group cross 104740-1100 ZEXEL

Isuzu

104740-1100

8941323760

INJECTION-PUMP ASSEMBLY

C223T

C223T