Information injection-pump assembly

BOSCH

9 460 613 155

9460613155

ZEXEL

104740-0962

1047400962

MAZDA

WL8313800A

wl8313800a

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-0962 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-0962 |

| 3. | NUMBER PLATE | 146995-4100 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | 146679-4120 |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1183 |

| 8. | Nozzle and Holder | PN40 13 H50C |

| 9. | Open Pre:MPa(Kqf/cm2) | 10.8{110} |

| 10. | NOZZLE-HOLDER | 105078-0111 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0720 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0420 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0400 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-5320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-4720 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-8420 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34C. | [1] | 146312-3000 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-3300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-7420 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146504-1120 | GOVERNOR COVER |

| 67/1. | [1] | 146806-4020 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/23. | [1] | 146934-3220 | BRACKET |

| 67/24. | [2] | 010206-2240 | HEX-SOCKET-HEAD CAP SCREW |

| 67/55. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/112. | [1] | 146934-6000 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-4100 | THREADED PIN |

| 67/201B. | [1] | 146545-4200 | THREADED PIN |

| 67/201C. | [1] | 146545-4300 | THREADED PIN |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146810-6920 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146832-0321 | CONTROL LEVER |

| 72B. | [1] | 146832-0421 | CONTROL LEVER |

| 72C. | [1] | 146832-1920 | CONTROL LEVER |

| 72D. | [1] | 146832-2020 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146865-6720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-6700 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146669-6720 | INLET UNION |

| 162. | [1] | 146625-8020 | PLATE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 146201-0100 | WOODRUFF KEY |

| 214. | [1] | 146542-1400 | BUSHING |

| 215. | [1] | 146542-1500 | BUSHING |

| 217. | [1] | 146542-2600 | SLOTTED WASHER |

| 218. | [1] | 146592-8400 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-8500 | COILED SPRING |

| 221. | [1] | 146934-9320 | BRACKET |

| 222. | [1] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 236. | [3] | 139006-4800 | BLEEDER SCREW |

| 236. | [3] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-4320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0600 | EYE BOLT |

| 247. | [1] | 146667-0820 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 275. | [1] | 146932-8000 | BRACKET |

| 309. | [2] | 139006-5700 | BLEEDER SCREW |

| 310. | [1] | 146685-2321 | POTENTCIOMETER |

| 310/1. | [1] | 146685-2310 | POTENTCIOMETER |

| 310/2. | [1] | 146934-6121 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146621-0500 | UNION NUT |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/7. | [1] | 146661-0401 | BOOT |

| 311. | [3] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 311. | [3] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 312. | [1] | 146934-9420 | BRACKET |

| 313. | [1] | 014010-5140 | PLAIN WASHER D12&5.5T0.8 |

| 314. | [1] | 014110-5440 | LOCKING WASHER |

| 315. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 317. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 318. | [1] | 146932-8320 | BRACKET |

| 370. | [1] | 146663-2720 | SPACER RING |

| 455. | [1] | 146849-3220 | RACK |

| 800S. | [1] | 146018-8420 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-5820 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146685-2410 | POTENTCIOMETER |

| 905. | [1] | 146679-4120 | ACTUATOR |

| 906. | [1] | 146995-4100 | NAMEPLATE |

| 912. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

Include in #2:

104740-0962

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 155

9460613155

ZEXEL

104740-0962

1047400962

MAZDA

WL8313800A

wl8313800a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

48.7

48.2

49.2

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

44.8

41.8

47.8

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

48.7

47.7

49.7

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

44.3

40.8

47.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

15.7

12.7

18.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

15.7

5.7

25.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

8

10

Difference in delivery

mm3/st.

1.7

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

7.5

10.5

Difference in delivery

mm3/st.

2.2

Basic

*

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

17

15

19

Difference in delivery

mm3/st.

3

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

55

90

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

50

90

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

569

540

598

Pressure

kgf/cm2

5.8

5.5

6.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

569

530

608

Pressure

kgf/cm2

5.8

5.4

6.2

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

5.7

5.5

5.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1.8

1

2.6

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

5.7

5.3

6.1

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

9.2

8.4

10

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

33.6

33.1

34.1

Timer stroke TA

mm

5.2

5

5.4

Timer stroke variation dT

mm

0.5

0.5

0.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

33.6

32.6

34.6

Timer stroke TA

mm

5.2

4.8

5.6

Timer stroke variation dT

mm

0.5

0.5

0.5

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

25

23.5

26.5

Timer stroke TA

mm

4.1

3.5

4.7

Timer stroke variation dT

mm

1.6

1.6

1.6

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.01

5.91

6.11

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.03

0.01

0.05

Control lever angle alpha

deg.

12.5

8.5

16.5

Control lever angle beta

deg.

40

37

43

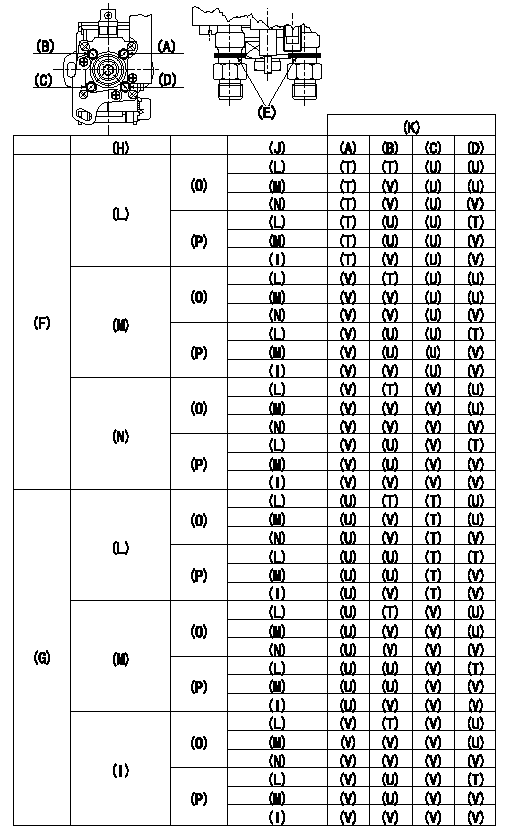

Test data Ex:

0000001801 CONTROL STANDARD AT IDLING

Standards for idle difference in delivery control

After idle adjustment, measure the idle injection quantities of (A) to (D).

Install the colored rings to the delivery valve holders (A) to (D) in accordance with the table.

(A): A cylinder (B) :B cylinder (C) : C cylinder (D): D cylinder

(E): Collar ring

(F): (A) >= (C)

(G): (C) > (A)

(H): (A) - (C) or (C) - (A)

(I): 0.2, 0.1(mm3/st)

(J): (B) - (D) or (D) - (B)

(K): Ring color

(L): At least 0.6 mm3/st

(M): 0.3, 0.4, 0.5 (mm3/st)

(N): 0.2, 0.1, 0.0 (mm3/st)

(O): (B) >= (D)

(P): (D) > (B)

(T): Yellow

(U): White

(V): Red

----------

----------

----------

----------

0000001901 POTENTIOMETER ADJUSTMENT

Confirm potentiometer output voltage

Control lever (1) Full position: V1 (Adjusting point)

(2)Idle position: V2 (checking point)

----------

V1=8.40+-0.03V V2=1.73+-0.7V

----------

----------

V1=8.40+-0.03V V2=1.73+-0.7V

----------

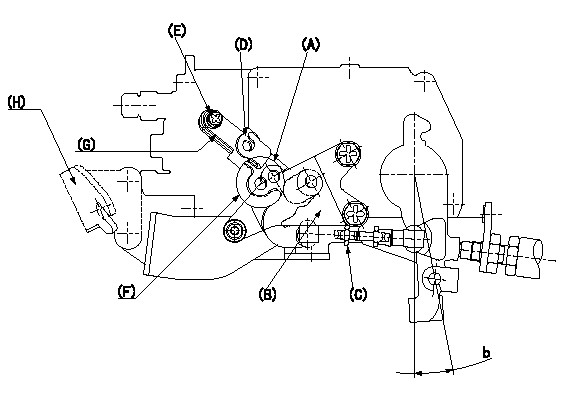

0000002001 A/T PLATE ADJUSTMENT

A/T link lever initial position setting

With the control lever at position a, adjust the length of connecting rod (C) so that the pin L1 can pass through the A/T link lever (A) and the bracket (B) at X. Then fix at torque T1.

A/T wire stroke adjustment

Mount the A/T wire stroke measuring apparatus and the mounting jig Y (bracket).

Slide the plate (D) so that the stroke becomes L2 and fix the bolt (E) to torque T2.

Remove jigs after adjustment.

(A): A/T link lever

(B): Bracket

(C): Rod

(D): Plate

(E): Bolt

(F): X

(G): Marking line

(H): Jig Y

----------

a=0deg L1=Dia.5.8-0.2mm L2=30+-2mm T1=2.5~2.9N-m(0.25~0.31kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m)

----------

b=(12.5deg)

----------

a=0deg L1=Dia.5.8-0.2mm L2=30+-2mm T1=2.5~2.9N-m(0.25~0.31kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m)

----------

b=(12.5deg)

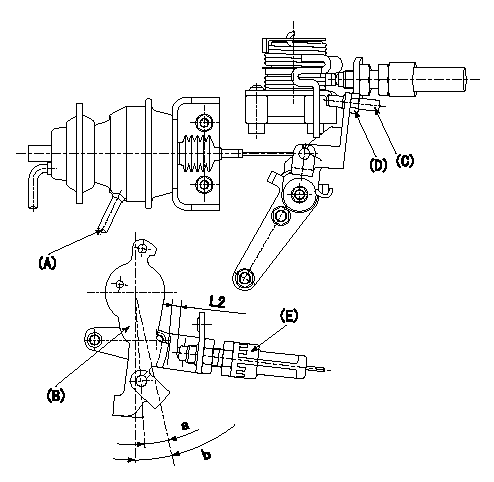

0000002101 WIRE

(1)Confirmation of the wire length:

Accelerator wire: Idle-full stroke: L1

(2)Confirmation on the idle SW

Confirm that the switch is ON at the idle lever position.

(3)Adjustment of the double stage actuator:

1. Apply negative pressure P1 to the actuator through the negative pressure suction inlet.

2. Under the conditions in 1. above, adjust using screw (C) so that the control lever () position is angle a [clearance L2+-0.5mm from idle switch (E)], and fix using the nut (D). (Tightening torque T)

b:Angle alpha

----------

L1=34.1+-3.5mm L2=3.3mm P1=-66.6kPa(-500mmHg) T=6~9N-m(0.6~0.9kgf-m) a=8.0deg b=12.5deg

----------

L2=(3.3mm) a=8.0deg b=12.5deg

----------

L1=34.1+-3.5mm L2=3.3mm P1=-66.6kPa(-500mmHg) T=6~9N-m(0.6~0.9kgf-m) a=8.0deg b=12.5deg

----------

L2=(3.3mm) a=8.0deg b=12.5deg

Information:

2. Remove "V" clamp (3). Remove the cartridge housing (5) from the turbine housing (4). 3. Install tool (C) in tool (B) and put the cartridge assembly in tool (C) as shown. Use tool (D) to remove the nut that holds compressor wheel (6).

When the nut is loosened, do not put a side force on the shaft.

The oil used to heat the compressor wheel must have a flash point (the temperature at which the oil will burn) above 400°F (204°C).

4. Install tool (H) on tool (E). Heat tool (E) to a temperature of 350°F (177°C). Install the cartridge assembly on tool (H) so that only the compressor wheel is in the oil. Heat the compressor wheel for no more than 10 minutes.

Do not let the turbine wheel hit the bottom of the press.

5. Install tool (H) on tool (G). Put the cartridge assembly in tool (H) as shown. Remove compressor wheel (6) with an arbor press and tool (F). Step 5 must be done before the compressor wheel becomes cooler. 6. Put the turbine wheel in tool (C). Remove seal ring (8) and shroud (7) from the shaft. 7. Bend the tabs of the locks from bolts (10) and remove the bolts and locks.8. Remove backplate assembly (11) from the cartridge housing. Remove spacer (9) from backplate assembly (11). Remove the seal rings from spacer (9).9. Remove the collar from behind backplate assembly (11). 10. Remove thrust bearing (13) and O-ring seal (12) from the cartridge housing. 11. Remove top bearing (14) and the washer from the cartridge housing. Put a long dye mark on the top face of bearing (14). 12. Use tool (J) and remove the two rings that hold top and bottom bearings in position. Remove the bottom bearing and washer. Put a short dye mark on the bearing. The dye marks are used for identification of the bearings when they are installed.13. Use tool (J) and remove the last ring that holds the bottom bearing in position from the cartridge housing.14. Check all the parts of the turbocharger for damage. If the parts have damage, use new parts for replacement. See SPECIAL INSTRUCTION FORM NO. SMHS6854 for TURBOCHARGER RECONDITIONING. Also see GUIDELINE FOR REUSABLE PARTS FORM NO. SEBF8018.Assemble Turbocharger (Airesearch TV81)

1. Make sure that all of the oil passages in the turbocharger cartridge housing are clean and free of dirt and foreign material.2. Put clean engine oil on all parts of the cartridge assembly.

Rings (1), (4) and (5) must be installed with the round edge of the rings toward the bearings.

3. Install ring (4) in the cartridge housing with tool (A).4. Install washer (3) and bearing (2) in the cartridge housing. Make sure the short dye mark on bearing (2) is up. 5. Install rings (1) and (5) in the cartridge housing with tool (A). Put 6V2055 High Vacuum Grease in the groove for seal ring (7) at assembly to one half or more of the depth of the groove all the way around.6.

When the nut is loosened, do not put a side force on the shaft.

The oil used to heat the compressor wheel must have a flash point (the temperature at which the oil will burn) above 400°F (204°C).

4. Install tool (H) on tool (E). Heat tool (E) to a temperature of 350°F (177°C). Install the cartridge assembly on tool (H) so that only the compressor wheel is in the oil. Heat the compressor wheel for no more than 10 minutes.

Do not let the turbine wheel hit the bottom of the press.

5. Install tool (H) on tool (G). Put the cartridge assembly in tool (H) as shown. Remove compressor wheel (6) with an arbor press and tool (F). Step 5 must be done before the compressor wheel becomes cooler. 6. Put the turbine wheel in tool (C). Remove seal ring (8) and shroud (7) from the shaft. 7. Bend the tabs of the locks from bolts (10) and remove the bolts and locks.8. Remove backplate assembly (11) from the cartridge housing. Remove spacer (9) from backplate assembly (11). Remove the seal rings from spacer (9).9. Remove the collar from behind backplate assembly (11). 10. Remove thrust bearing (13) and O-ring seal (12) from the cartridge housing. 11. Remove top bearing (14) and the washer from the cartridge housing. Put a long dye mark on the top face of bearing (14). 12. Use tool (J) and remove the two rings that hold top and bottom bearings in position. Remove the bottom bearing and washer. Put a short dye mark on the bearing. The dye marks are used for identification of the bearings when they are installed.13. Use tool (J) and remove the last ring that holds the bottom bearing in position from the cartridge housing.14. Check all the parts of the turbocharger for damage. If the parts have damage, use new parts for replacement. See SPECIAL INSTRUCTION FORM NO. SMHS6854 for TURBOCHARGER RECONDITIONING. Also see GUIDELINE FOR REUSABLE PARTS FORM NO. SEBF8018.Assemble Turbocharger (Airesearch TV81)

1. Make sure that all of the oil passages in the turbocharger cartridge housing are clean and free of dirt and foreign material.2. Put clean engine oil on all parts of the cartridge assembly.

Rings (1), (4) and (5) must be installed with the round edge of the rings toward the bearings.

3. Install ring (4) in the cartridge housing with tool (A).4. Install washer (3) and bearing (2) in the cartridge housing. Make sure the short dye mark on bearing (2) is up. 5. Install rings (1) and (5) in the cartridge housing with tool (A). Put 6V2055 High Vacuum Grease in the groove for seal ring (7) at assembly to one half or more of the depth of the groove all the way around.6.