Information injection-pump assembly

BOSCH

9 460 610 499

9460610499

ZEXEL

104740-0511

1047400511

MAZDA

PN6213800A

pn6213800a

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-0511 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-0511 |

| 3. | NUMBER PLATE | 146960-2900 |

| 4. | _ | 146672-5420 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1183 |

| 8. | Nozzle and Holder | PN40 13 H50C |

| 9. | Open Pre:MPa(Kqf/cm2) | 10.8{110} |

| 10. | NOZZLE-HOLDER | 105078-0111 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0720 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2620 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-1320 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-3900 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-8400 | COMPRESSION SPRING |

| 34B. | [1] | 146302-8800 | COMPRESSION SPRING |

| 34C. | [1] | 146302-8100 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0120 | GUIDE PIN |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3420 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-6620 | GOVERNOR COVER |

| 67/1. | [1] | 146508-4921 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/23. | [1] | 146929-3920 | BRACKET |

| 67/24. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/68. | [1] | 146620-3400 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146513-8920 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146539-5520 | CONTROL LEVER |

| 72B. | [1] | 146539-5620 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 80. | [1] | 146539-2600 | CONTROL LEVER |

| 81. | [2] | 020105-1040 | BLEEDER SCREW M5P0.8L10 |

| 95. | [1] | 146851-0220 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-6800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-1120 | OVER FLOW VALVE |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 146608-3220 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 214. | [1] | 146542-1400 | BUSHING |

| 215. | [1] | 146542-1500 | BUSHING |

| 220. | [1] | 146592-2700 | COILED SPRING |

| 221. | [1] | 146928-9320 | BRACKET |

| 232. | [1] | 146659-3600 | CLAMPING BAND |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-4320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-0820 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146665-3620 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 252. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 275. | [1] | 146612-6100 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-8921 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 316. | [1] | 146680-4620 | DAMPER |

| 317. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 800S. | [1] | 146019-8920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-5420 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146960-2900 | NAMEPLATE |

Include in #2:

104740-0511

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 610 499

9460610499

ZEXEL

104740-0511

1047400511

MAZDA

PN6213800A

pn6213800a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

31.8

31.3

32.3

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

12.4

9.9

14.9

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.1

27.1

33.1

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

31.8

30.8

32.8

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

30.2

28.2

32.2

Injection quantity adjustment

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

12.4

10.4

14.4

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

7

6

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Governor adjustment_03

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

7

5.5

8.5

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

60

80

Basic

*

Speed control lever angle

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

435

306

564

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Stop lever angle_03

Pump speed

r/min

2350

2350

2350

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.2

6

6.4

Basic

*

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1

_03

Pump speed

r/min

875

875

875

Timer stroke

mm

2.1

1.3

2.9

_04

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.9

2.3

3.5

_05

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.2

5.9

6.5

_06

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

9.6

8.6

10.6

_07

Pump speed

r/min

2350

2350

2350

Timer stroke

mm

9.8

9.4

10.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

19.5

20.5

Timer stroke variation dT

mm

1

0.8

1.2

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

19

21

Timer stroke variation dT

mm

1

0.7

1.3

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

10

8.5

11.5

Timer stroke variation dT

mm

1.7

1.4

2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.72

5.62

5.82

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

43

38

48

Test data Ex:

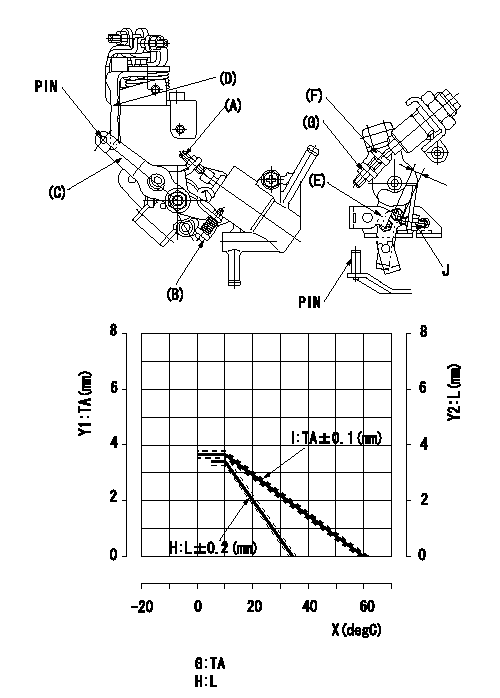

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the graph.

(2)Adjust screw A so that the timer advance angle determined in item (1) is obtained.

2. Adjustment of the W-FICD

(1)Insert block gauge thickness L (determined from the graph) between the control lever D's adjusting screw and the idle stopper (E)

(2)Adjust using screw B so that the control lever contacts the FICD lever pin and fix using the nut.

Y1 = timer stroke TA

Y2 = control lever gap L

X = temperature t

G = timer stroke TA:

H = control lever gap L:

J = adjusting screw

----------

----------

TA=-0.0738t+4.428 (t>=10degC) L=-0.144t+4.94 (t>=10decC)

----------

----------

TA=-0.0738t+4.428 (t>=10degC) L=-0.144t+4.94 (t>=10decC)

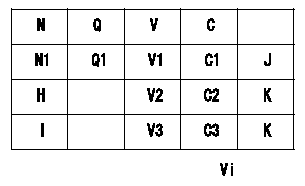

0000001901 DASHPOT ADJUSTMENT

Adjustment of the dash pot

With the control lever (D) at position a (clearance L), adjust so that the dashpot adjusting screw (F) contacts the end of the pushrod. Fix using the nut (G).

Adjusting method (dummy bolt method)

N = pump speed

Q = injection quantity

V = potentiometer output voltage

C = control lever angle

H = idle lever position

I = full speed lever position

J = adjusting point

K = check point

----------

L=7.1+-0.4mm a=17+-1deg

----------

N1=1000r/min Q1=20.8+-1.0mm3/st V1=4.66+-0.03V V2=(1.00V) V3=(7.80V) C1=(20.5deg) C2=0deg C3=43+-5deg Vi=10.00V

----------

L=7.1+-0.4mm a=17+-1deg

----------

N1=1000r/min Q1=20.8+-1.0mm3/st V1=4.66+-0.03V V2=(1.00V) V3=(7.80V) C1=(20.5deg) C2=0deg C3=43+-5deg Vi=10.00V

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Program can only be administered after a failure occurs. The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS5331" as the Part Number and "7755" as the Group Number. Use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

October 31, 1998Problem

Some 3116 and 3126 HEUI Engines may have excessive oil consumption as a result of oil leaking past the intensifier piston o-ring inside the injector. Engine oil consumption becomes excessive and may increase rapidly. There are no traditional signs of oil consumption, smoke, blow-by, etc. The engine has no performance problem, has good power and normal exhaust smoke.

The problem seems to be very low frequency and is not batch related.

Affected Product

Model & Identification Number

3116 (8WL1-Up)

3126 (1WM1-Up 4ES1-Up )

Parts Needed

3116 Engines6 - 1162784 Injectors (for 170 Hp)6 - 1166706 Injectors (for 185, 195, 215, 230, 250 and 275 Hp) 3126 Engines6 - 0R4970 Injectors (for 230, 250, 275, 300 and 330 Hp)6 - 0R4972 Injectors (for 175, 190 and 210 Hp)Action Required

See the attached rework procedure.

Service Claim Allowances

Labor Hour Breakdown TK = TopKickMC = Medium Hood ConventionalClaim 1290-500 for an additional 1.6 hours if the repair is made in a motor home chassis, cab type (RV), or bus chassis, cab type (BU).

Parts Disposition

TEPS/MEPS Dealers must return the affected part(s) to their Caterpillar dealer.

Parts must be returned undamaged in the original shipping boxes to:

Caterpillar Inc.

Attn: Michael Mosley - PS5331

8401 N. University

Peoria, Illinois 61615

Injectors must be sealed in a plastic bag to prevent fuel from leaking out during shipment.

A clear, legible copy of the service report in a plastic page protector must be included in the box with the returned injectors. The report must be packaged to arrive free of oil, grease and diesel fuel.

Attach.(1 - Rework Procedure)Rework Procedure

Check to see if PS8826 (Jumper-tube Rework) is to be applied to the affected engine. Perform PS8826 if it has not been performed prior to oil consumption test.

Document the oil consumption for 30 days using the attached Oil Consumption Test Sheet, Form Number 01-081227.

All of the following steps must be followed in order to establish base line data for oil consumption for full warranty reimbursement.

1. Change oil and filter at the beginning of the test to establish base line at normal change interval. Use CG-4 oil and new oil filter. Oil and filter are not claimable under this letter.

2. Refill with the proper amount of oil; 27liters/29 quarts, and 18 liters/19 quarts per the July 1997 Operations Maintenance Manual.3. Inspect for external leaks around the gaskets and the front and rear main seals.4. Inspect the air compressor air tanks for excess oil.5. Inspect the turbo oil drain line for excessive oil indicating seal leak.6. At the completion of

This Program can only be administered after a failure occurs. The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS5331" as the Part Number and "7755" as the Group Number. Use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

October 31, 1998Problem

Some 3116 and 3126 HEUI Engines may have excessive oil consumption as a result of oil leaking past the intensifier piston o-ring inside the injector. Engine oil consumption becomes excessive and may increase rapidly. There are no traditional signs of oil consumption, smoke, blow-by, etc. The engine has no performance problem, has good power and normal exhaust smoke.

The problem seems to be very low frequency and is not batch related.

Affected Product

Model & Identification Number

3116 (8WL1-Up)

3126 (1WM1-Up 4ES1-Up )

Parts Needed

3116 Engines6 - 1162784 Injectors (for 170 Hp)6 - 1166706 Injectors (for 185, 195, 215, 230, 250 and 275 Hp) 3126 Engines6 - 0R4970 Injectors (for 230, 250, 275, 300 and 330 Hp)6 - 0R4972 Injectors (for 175, 190 and 210 Hp)Action Required

See the attached rework procedure.

Service Claim Allowances

Labor Hour Breakdown TK = TopKickMC = Medium Hood ConventionalClaim 1290-500 for an additional 1.6 hours if the repair is made in a motor home chassis, cab type (RV), or bus chassis, cab type (BU).

Parts Disposition

TEPS/MEPS Dealers must return the affected part(s) to their Caterpillar dealer.

Parts must be returned undamaged in the original shipping boxes to:

Caterpillar Inc.

Attn: Michael Mosley - PS5331

8401 N. University

Peoria, Illinois 61615

Injectors must be sealed in a plastic bag to prevent fuel from leaking out during shipment.

A clear, legible copy of the service report in a plastic page protector must be included in the box with the returned injectors. The report must be packaged to arrive free of oil, grease and diesel fuel.

Attach.(1 - Rework Procedure)Rework Procedure

Check to see if PS8826 (Jumper-tube Rework) is to be applied to the affected engine. Perform PS8826 if it has not been performed prior to oil consumption test.

Document the oil consumption for 30 days using the attached Oil Consumption Test Sheet, Form Number 01-081227.

All of the following steps must be followed in order to establish base line data for oil consumption for full warranty reimbursement.

1. Change oil and filter at the beginning of the test to establish base line at normal change interval. Use CG-4 oil and new oil filter. Oil and filter are not claimable under this letter.

2. Refill with the proper amount of oil; 27liters/29 quarts, and 18 liters/19 quarts per the July 1997 Operations Maintenance Manual.3. Inspect for external leaks around the gaskets and the front and rear main seals.4. Inspect the air compressor air tanks for excess oil.5. Inspect the turbo oil drain line for excessive oil indicating seal leak.6. At the completion of