Information injection-pump assembly

BOSCH

9 460 612 472

9460612472

ZEXEL

104740-0403

1047400403

MAZDA

PN4113800E

pn4113800e

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-0403 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-0403 |

| 3. | NUMBER PLATE | 146960-0300 |

| 4. | _ | 146672-5520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1183 |

| 8. | Nozzle and Holder | PN40 13 H50C |

| 9. | Open Pre:MPa(Kqf/cm2) | 10.8{110} |

| 10. | NOZZLE-HOLDER | 105078-0111 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0100 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0720 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2620 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-1320 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-3900 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146302-8400 | COMPRESSION SPRING |

| 34B. | [1] | 146302-8800 | COMPRESSION SPRING |

| 34C. | [1] | 146302-8100 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0000 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0120 | GUIDE PIN |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-2820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-3420 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-4821 | GOVERNOR COVER |

| 67/1. | [1] | 146508-4921 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/24. | [4] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/64. | [1] | 146927-5800 | BRACKET |

| 67/78. | [1] | 146600-1000 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146513-8920 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146536-7200 | CONTROL LEVER |

| 72B. | [1] | 146536-7300 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 78. | [1] | 146549-8720 | CONTROL LEVER |

| 80. | [1] | 146547-8220 | CONTROL LEVER |

| 85. | [1] | 146549-7520 | RACK |

| 95. | [1] | 146851-0220 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-6800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-1120 | OVER FLOW VALVE |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 146608-3220 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 220. | [1] | 146592-1600 | COILED SPRING |

| 221. | [1] | 146927-9220 | BRACKET |

| 223. | [1] | 146670-9620 | SWITCH |

| 232. | [1] | 146659-3600 | CLAMPING BAND |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-4320 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146608-4920 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 252. | [1] | 139006-4400 | BLEEDER SCREW |

| 275. | [1] | 146612-5800 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146360-9020 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 310. | [1] | 146673-9720 | POTENTCIOMETER |

| 800S. | [1] | 146019-8920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-5520 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146960-0300 | NAMEPLATE |

Include in #2:

104740-0403

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 472

9460612472

ZEXEL

104740-0403

1047400403

MAZDA

PN4113800E

pn4113800e

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

30.3

29.8

30.8

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

12.4

9.9

14.9

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

28.6

25.6

31.6

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

30.3

29.3

31.3

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

28.7

26.7

30.7

Injection quantity adjustment

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

12.4

10.4

14.4

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

7

6

8

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

7

6

8

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

60

80

Basic

*

Speed control lever angle

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

435

306

564

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

539.5

520

559

Pressure

kgf/cm2

5.5

5.3

5.7

Stop lever angle_03

Pump speed

r/min

2350

2350

2350

Pressure

kPa

745.5

716

775

Pressure

kgf/cm2

7.6

7.3

7.9

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.2

6

6.4

Basic

*

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1

_03

Pump speed

r/min

875

875

875

Timer stroke

mm

2.1

1.5

2.7

_04

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.9

2.5

3.3

_05

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.2

5.9

6.5

_06

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

9.5

8.6

10.4

_07

Pump speed

r/min

2350

2350

2350

Timer stroke

mm

9.8

9.4

10.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

19.5

20.5

Timer stroke TA

mm

1.9

1.7

2.1

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

19

21

Timer stroke TA

mm

1.9

1.6

2.2

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

10

8.5

11.5

Timer stroke TA

mm

1.2

0.5

1.9

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.72

5.62

5.82

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

43

40

46

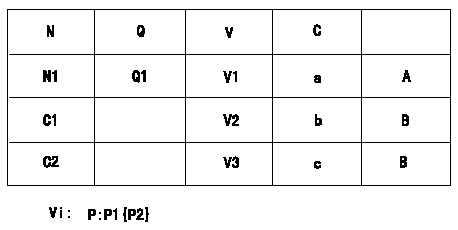

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

N:Pump speed

Q:Injection quantity

V:Output voltage

C:Position of the control lever

C1:Idle

C2:Full

A:Adjusting point

B:Checking point

P:Boost pressure

Vi:Applied voltage

----------

----------

N1=1000r/min Vi=10.00V Q1=20.8+-1.0cm3/1,000st V1=4.66+-0.03V V2=(1.00)V V3=(7.80)V P1=-kPa P2=-mmHg a=(20.5)deg b=0deg c=43+-3deg

----------

----------

N1=1000r/min Vi=10.00V Q1=20.8+-1.0cm3/1,000st V1=4.66+-0.03V V2=(1.00)V V3=(7.80)V P1=-kPa P2=-mmHg a=(20.5)deg b=0deg c=43+-3deg

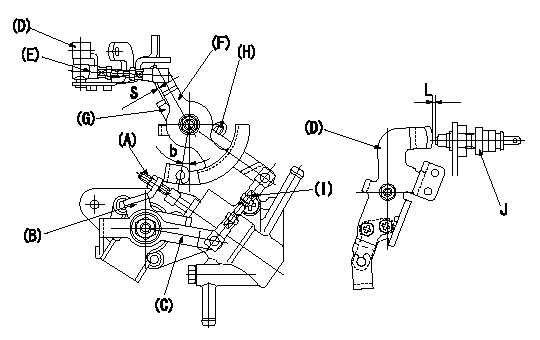

0000001901 SIDE LINK LEVER ADJUSTMENT

Side link lever adjustment

1. Adjusting the side link lever

Hold the control lever (D) at position a.

With the side link lever (G) contacting the stopper (H), turn the A/T lever (F) lightly clockwise to eliminate any rod (E) play.

At this time, adjust the length of rod (E) so that the gap between the A/T lever (F) and the lever (G) is S. Then fix.

J = idle switch

L = the dimension when the switch is depressed (ie, on)

----------

a=0deg S=1+-0.2mm

----------

S=1+-0.2mm b=10deg

----------

a=0deg S=1+-0.2mm

----------

S=1+-0.2mm b=10deg

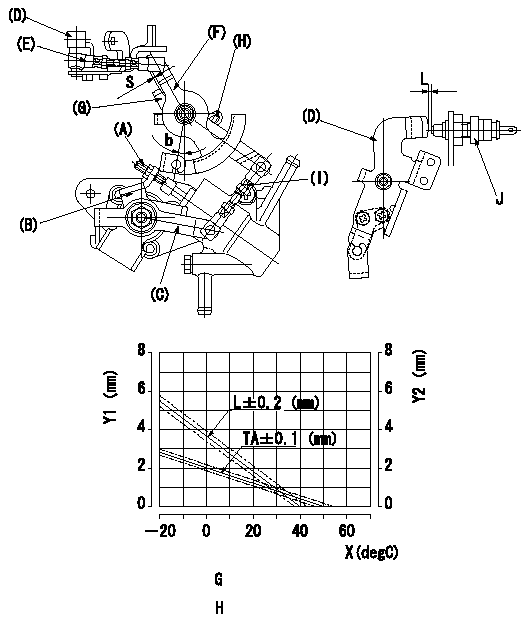

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the graph.

(2)Adjust screw A so that the timer advance angle determined in item (1) is obtained.

2. Adjustment of the W-FICD

Adjust the rod (I) so that the clearance from the control lever is L as determined from the graph.

At this time, CSD lever (B) and FICD lever (C) must contact. When the FICD lever is rotated clockwise, confirm that (D), (E), (F), (G), and (H) operate with no play.

Y1 = timer stroke TA

Y2 = control lever gap L

X = temperature t

G = timer stroke TA:

H = control lever gap L:

----------

----------

TA=-0.041t+2.46 (t>=-20degC) L=-0.0925t+3.65 (t>=-20decC)

----------

----------

TA=-0.041t+2.46 (t>=-20degC) L=-0.0925t+3.65 (t>=-20decC)

Information:

Table 4

Cat Specification for Neat (B100) Biodiesel Blending Fuel

Property Test Method, United States Test Method, International Units Limits, B100 Blending Fuel

Density at 15°C “ASTM D1298” “ISO 3675” g/cm3 0.86-0.90

Viscosity at 40°C “ASTM D445” “ISO 3104” mm2/s (cSt) 1.9-6.0

Flash Point “ASTM D93” “ISO 3679” °C 93 minimum

Pour Point - - - 6 °C (10 °F) minimum below ambient temperature

- Summer “ASTM D97” “ISO 3016” °C

- Winter

Cloud Point “ASTM D2500” °C Report

Sulfur Content(1) “ASTM D5453” “ISO 20846” “ISO 20884” percent weight 0.0015(2) maximum

Distillation - - - -

T90 “ASTM D86” “ISO 3924” °C 360

Cetane Number “ASTM D613” “ISO 5165” % evaporation 45 minimum

Sulfated Ash “ASTM D874” “ISO 3987” or "ISO 6245" percent weight 0.02 maximum

Water and Sediment “ASTM D2709” “ISO 12937” percent volume 0.05 maximum

Water "ASTM D1796" "EN ISO 12937" % m/m -

Copper Corrosion, 3 hours at 50oC “ASTM D130” “ISO 2160” - No. 1

Oxidation Stability “EN 14112” or "EN 15751" “EN 14112” or "EN 15751" hours 3 minimum

Ramsbottom Carbon Residue on 10% bottoms "ASTM D524" “ISO 10370” %-m/m 0.30 maximum

Carbon Residue, Conradson (CCR) “ASTM D4530” - percent weight 0.05 maximum

Esterification "ASTM D 7806" or "ASTM D 7371" “EN 14103” percent volume 97.5 minimum

Total Acid Number “ASTM D664” “EN 14104” mg KOH/g 0.5 maximum

Methanol Content “EN 14110” “EN 14110” percent weight 0.2 maximum

Monoglycerides “ASTM D6584” “EN 14105” percent weight 0.8 maximum

Diglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Triglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Free Glycerin “ASTM D6584” “EN 14105” percent weight 0.02 maximum

Total Glycerin “ASTM D6584” “EN 14105” percent weight 0.240 maximum

Phosphorus Content “ASTM D4951” “EN 14107” percent weight 0.001 maximum

Calcium plus Magnesium “EN 14538” “EN 14538” ppm 5 maximum

Sodium plus Potassium “EN 14538” “EN 14538” ppm 5 maximum

Cold Soak Filterability “ASTM D7501” – seconds 360 maximum

Cleanliness “ASTM D7619” “ISO 4406” – (3)

Total contamination "EN 12662" "EN 12662" mg/kg 24 maximum

Appearance "ASTM D4176" - - Clear and Bright

(1) Methods for testing S are based on the sulfur content in diesel fuel used for blending. Consult with the fuel supplier and ensure the correct method has been used

(2) Sulfur level must be per local regulations. Higher S levels may be used where allowed.

(3) Recommended cleanliness level for fuel as dispensed into the engine fuel tank is ISO 18/16/13 or cleaner per the test methods listed. Refer to the contamination control Chapter for more details.Note: Fuels that meet the most current revision level of "ASTM D6751" or "EN 14214" may be used for blending with an acceptable distillate fuel. The conditions, recommendations, and limits that are noted in this Biodiesel section apply.Referenced Documents

Refer to the “Reference Material - Fuel” section of this Special Publication for the reference material for the information in this section.