Information injection-pump assembly

ZEXEL

104740-0400

1047400400

MAZDA

PN4113800

pn4113800

Rating:

Cross reference number

ZEXEL

104740-0400

1047400400

MAZDA

PN4113800

pn4113800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

29.2

28.7

29.7

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

16.8

14.3

19.3

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

31.5

29.5

33.5

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

29.2

28.2

30.2

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

28

26

30

Injection quantity adjustment

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

16.8

14.8

18.8

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2850

2850

2850

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

11.3

10.3

12.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

11.3

10.3

12.3

Governor adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

55

75

Basic

*

Speed control lever angle

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

450

318

582

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

637.5

608

667

Pressure

kgf/cm2

6.5

6.2

6.8

Basic

*

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

637.5

608

667

Pressure

kgf/cm2

6.5

6.2

6.8

Stop lever angle_03

Pump speed

r/min

2350

2350

2350

Pressure

kPa

825.5

814

837

Pressure

kgf/cm2

8.6

8.3

8.9

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.8

6.6

7

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

4.1

3.7

4.5

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

6.8

6.6

7

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

9.6

9.2

10

_05

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

11.05

10.6

11.5

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

22.5

22

23

Timer stroke variation dT

mm

1.2

1

1.4

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

22.5

21.5

23.5

Timer stroke variation dT

mm

1.2

0.9

1.5

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

14

12.5

15.5

Timer stroke variation dT

mm

2.4

1.9

2.9

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.72

5.62

5.82

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

43

40

46

Test data Ex:

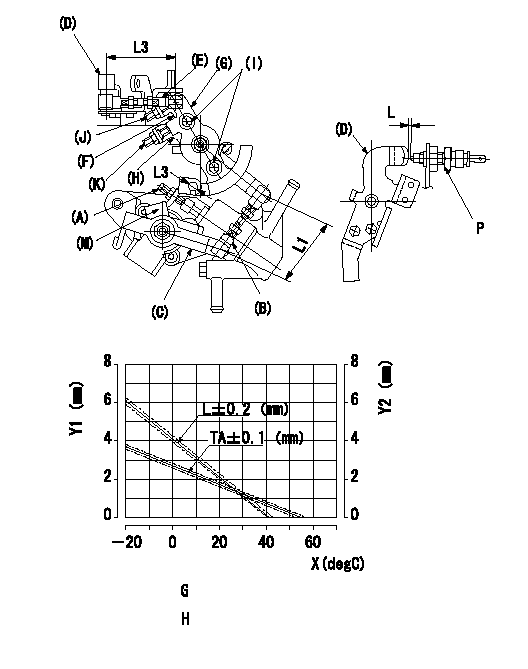

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the graph.

(2)Adjust screw A so that the timer advance angle determined in item (1) is obtained.

2. Adjustment of the W-FICD

Adjust the screw (K) so that the control lever clearance is L as determined from the graph, then fix.

At this time, the CSD lever (B)'s length must be 1 mm.

Ensure the CSD lever (O) and the FICD lever (C) are contacting each other and confirm that (D), (E), (B), (G) and (H) operate with no play when the FICD lever is turned clockwise.

Y1 = timer stroke TA

P = idle switch

Y2 = control lever gap L

X = temperature t

G = timer stroke TA:

H = control lever gap L:

----------

L1=53+-0.5mm

----------

TA=-0.049t+2.73 L=-0.0975t+4.15 L1=53+-0.5mm L2=53+-0.5mm a=10+-1deg L3=Dia.6.2mm

----------

L1=53+-0.5mm

----------

TA=-0.049t+2.73 L=-0.0975t+4.15 L1=53+-0.5mm L2=53+-0.5mm a=10+-1deg L3=Dia.6.2mm

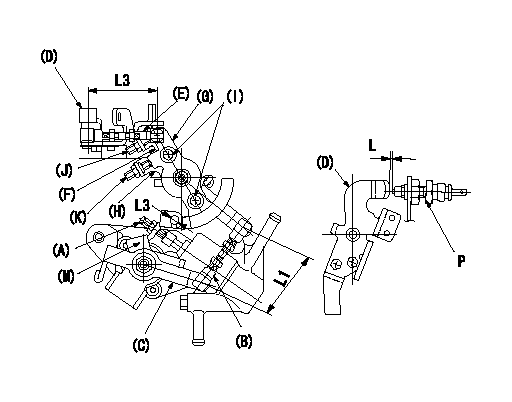

0000001901 SIDE LINK LEVER ADJUSTMENT

Side link lever adjustment

1. Adjusting the side link lever

Hold the control lever (D) at position a.

Adjust the length of rod (E) to 1 mm and fix.

Adjust screw (J) so that the center of the A/T lever(G)'s hole L2 is b, then fix the screw.

At this time, fix the A/T lever (G) and the lever (F) using bolt (I).

P = idle switch

----------

a=0deg L1=53+-0.5mm L2=Dia.6.2mm b=10+-1deg

----------

L1=53+-0.5mm L2=Dia.6.2mm L3=53+-0.5mm b=10+-1deg

----------

a=0deg L1=53+-0.5mm L2=Dia.6.2mm b=10+-1deg

----------

L1=53+-0.5mm L2=Dia.6.2mm L3=53+-0.5mm b=10+-1deg

Information:

Install the new 291-5165 Bellows (10) to tube assembly (2) by placing the end of the bellows with the liner on the flange of the tube assembly. Secure bellows (10) to tube assembly (2) by using one new 202-1838 V Band Clamp (11). Refer to Illustration 7.

Illustration 8 g01794917

(12) 313-9428 Tube As

Install the flanged end of the new 313-9428 Tube As (12) to bellows (10) by using one new V-band clamp (11). Refer to Illustration 8.Note: Make sure that the tube assembly is temporarily supported so that the tube assembly axis lines up with the axis of the bellows before securing the tube assembly to the bellows. That way the weight of the tube is on the support and not on the bellows.

Illustration 9 g01794933

(13) 294-9631 Clamp As (14) 310-7675 Bracket (15) 5P-1076 Hard Washer (16) 8T-4183 Bolt

Install the bottom half of the new 294-9631 Clamp As (13) to the two new 310-7675 Brackets (14) by using two new 5P-1076