Information injection-pump assembly

ZEXEL

104740-0260

1047400260

MAZDA

SE4213800

se4213800

Rating:

Cross reference number

ZEXEL

104740-0260

1047400260

MAZDA

SE4213800

se4213800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

52.6

52.1

53.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

22.1

19.1

25.1

Injection timing adjustment_03

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

47.4

45.4

49.4

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

51.3

49.3

53.3

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

52.6

51.6

53.6

Injection timing adjustment_06

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

46.6

44.6

48.6

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

22.1

19.1

25.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

6

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12.8

10.8

14.8

Difference in delivery

mm3/st.

2.5

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12.8

10.8

14.8

Governor adjustment_03

Pump speed

r/min

620

Average injection quantity

mm3/st.

0

0

0

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

78

78

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

450

318

582

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

588.5

559

618

Pressure

kgf/cm2

6

5.7

6.3

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

255

226

284

Pressure

kgf/cm2

2.6

2.3

2.9

Stop lever angle_03

Pump speed

r/min

1500

1500

1500

Pressure

kPa

588.5

559

618

Pressure

kgf/cm2

6

5.7

6.3

Stop lever angle_04

Pump speed

r/min

1900

1900

1900

Pressure

kPa

725.5

696

755

Pressure

kgf/cm2

7.4

7.1

7.7

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

5.2

5

5.4

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.2

1.6

2.8

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

5.2

4.9

5.5

_04

Pump speed

r/min

1900

1900

1900

Timer stroke

mm

7.6

7

8.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1000

1000

1000

Atmospheric pressure difference

kPa

-18.7

-18.7

-18.7

Atmospheric pressure difference

mmHg

-140

-140

-140

Average injection quantity

mm3/st.

47.7

46.7

48.7

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Atmospheric pressure difference

kPa

-18.7

-18.7

-18.7

Atmospheric pressure difference

mmHg

-140

-140

-140

Average injection quantity

mm3/st.

47.7

46.2

49.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

38

33

43

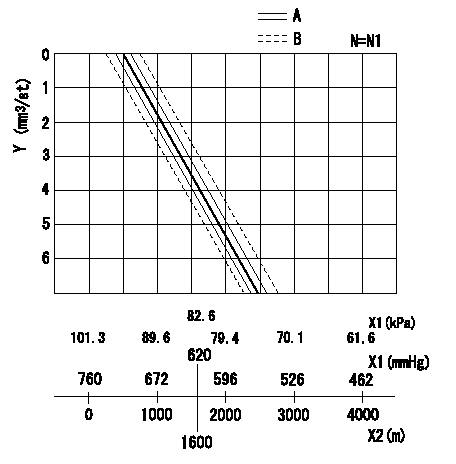

Test data Ex:

0000001501 ANEROID COMPENSATOR

ACS adjustment

Full load injection quantity at high altitudes and ACS adjusting method

1. Full load injection quantity adjustment

(1)Remove the ACS cover and remove the bellows and adjusting shim.

(2)Perform all adjustments as per the adjustment standard except for ACS adjustment.

2. ACS adjustment

(1)Assemble the ACS cover, bellows and adjusting shim.

(2)At N = N1, adjust using shims so that the decrease amount for altitude is as specified in the graph.

N:Pump speed

X1:Atmospheric pressure

X2:Altitude

Y:Decrease quantity

A:Adjustment value

B:Inspection value

----------

N1=1000r/min

----------

----------

N1=1000r/min

----------

Information:

CHECKING FLYWHEEL FACE RUNOUT4. The difference between the lowest and highest readings taken at all four points should not exceed .006 in. (0.15 mm), which is the maximum permissible flywheel face runout.Checking Flywheel Bore Runout

CHECKING FLYWHEEL BORE RUNOUT

1. 7H1945 Holding Rod. 2. 7H1645 Holding Rod. 3. 7H1942 Indicator. 4. 7H1940 Universal Attachment.Make tool setup from parts of the 8S2328 Dial Test Indicator Group.1. Mount the dial indicator and adjust it so the universal attachment contacts the flywheel bore as shown.2. Adjust the dial indicator to read .000 in. (0.0 mm) then take readings every 90° around the flywheel.3. The difference between the lowest and highest readings taken at all four points should not exceed .006 in. (0.15 mm), which is the maximum permissible flywheel bore runout. Flywheel clutch pilot bearing bore runout should not exceed .005 in. (0.13 mm).

CHECKING FLYWHEEL CLUTCH PILOT BEARING BOREElectrical System

Most of the testing of the electrical system can be done on the engine. The wiring insulation must be in good condition, the wire and cable connections clean and tight and the battery fully charged. If on the engine test shows a defect in a component, remove the component for more testing. The wire size, color and recommendations of length are given in the WIRING DIAGRAMS in SYSTEMS OPERATION.Battery

9S1990 Battery Charger Tester.The battery circuit is an electrical load on the charging unit. The load is variable because of the condition of the charge in the battery. Damage to the charging unit will result, if the connections, (either positive or negative) between the battery and charging unit are broken while the charging unit is charging. This is because the battery load is lost and there is an increase in charging voltage.High voltage will damage, not only the charging unit but also the regulator and other electrical components.

9S1990 BATTERY CHARGER TESTER

Never disconnect any charging unit circuit or battery circuit cable from battery when the charging unit is charging.

Load test a battery that does not hold a charge when in use. To do this, put a resistance, across the battery main connections (terminals). For a 6 volt battery, put a resistance of two times the ampere/hour rating of the battery. For a 12 volt battery, put a resistance of three times the ampere/hour rating. Let the resistance remove the charge (discharge the battery) for 15 seconds. Immediately test the battery voltage. A 6 volt battery in good condition will test 4.5 volts; a 12 volt battery in good condition will test 9 volts.The Special Instruction (GEG00058) with the 9S1990 Charger Tester gives the battery testing procedure.Charging System

Battery

The condition of charge in the battery at each regular inspection will show if the charging system is operating correctly. An adjustment is necessary when the battery is always in a low condition of charge or a large amount of water is needed (one ounce per cell per week or every 50 service hours).Test the charging units and voltage regulators on the engine, when possible, using wiring and components that are