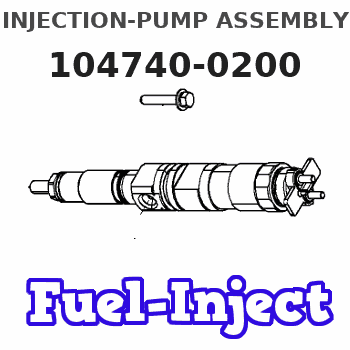

Information injection-pump assembly

ZEXEL

104740-0200

1047400200

MAZDA

483413800

483413800

Rating:

Cross reference number

ZEXEL

104740-0200

1047400200

MAZDA

483413800

483413800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

(Note)

For Japan: year/month/day (change sequence) 1988/08/05 (1)

For Japan: year/month/day (change sequence) 1988/08/05 (1)

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

52.25

49.5

55

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

1380

1380

1380

Average injection quantity

mm3/st.

16.2

13.2

19.2

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

55

53

57

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55

54

56

Injection timing adjustment_05

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

48.8

46.8

50.8

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

53.6

53.1

54.1

Difference in delivery

mm3/st.

3.5

Basic

*

Remarks

For Japan

For Japan

Injection timing adjustment_07

Pump speed

r/min

1380

1380

1380

Average injection quantity

mm3/st.

15.8

12.8

18.8

Remarks

For Japan

For Japan

Injection timing adjustment_08

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

53.6

51.6

55.6

Remarks

For Japan

For Japan

Injection timing adjustment_09

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

53.6

52.6

54.6

Remarks

For Japan

For Japan

Injection timing adjustment_10

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

47.6

45.6

49.6

Remarks

For Japan

For Japan

Injection quantity adjustment

Pump speed

r/min

1380

1380

1380

Average injection quantity

mm3/st.

16.2

14.2

18.2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

1430

1430

1430

Average injection quantity

mm3/st.

6.2

Injection quantity adjustment_03

Pump speed

r/min

1380

1380

1380

Average injection quantity

mm3/st.

15.8

12.8

18.8

Basic

*

Remarks

For Japan

For Japan

Injection quantity adjustment_04

Pump speed

r/min

1430

1430

1430

Average injection quantity

mm3/st.

6

Remarks

For Japan

For Japan

Governor adjustment

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

13.1

11.1

15.1

Difference in delivery

mm3/st.

2.5

Basic

*

Governor adjustment_02

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

13.1

11.1

15.1

Governor adjustment_03

Pump speed

r/min

620

Average injection quantity

mm3/st.

0

0

0

Governor adjustment_04

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

12.8

10.8

14.8

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

For Japan

For Japan

Governor adjustment_05

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

12.8

10.8

14.8

Remarks

For Japan

For Japan

Governor adjustment_06

Pump speed

r/min

620

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan

For Japan

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80.4

80.4

Basic

*

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

78

78

Basic

*

Remarks

For Japan

For Japan

Speed control lever angle

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan: Magnet OFF

For Japan: Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

450

318

582

_02

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

450

318

582

Remarks

For Japan

For Japan

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

431.5

402

461

Pressure

kgf/cm2

4.4

4.1

4.7

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

264.5

235

294

Pressure

kgf/cm2

2.7

2.4

3

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

431.5

402

461

Pressure

kgf/cm2

4.4

4.1

4.7

Stop lever angle_04

Pump speed

r/min

1250

1250

1250

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Stop lever angle_05

Pump speed

r/min

1000

1000

1000

Pressure

kPa

421.5

392

451

Pressure

kgf/cm2

4.3

4

4.6

Basic

*

Remarks

For Japan

For Japan

Stop lever angle_06

Pump speed

r/min

500

500

500

Pressure

kPa

255

226

284

Pressure

kgf/cm2

2.6

2.3

2.9

Remarks

For Japan

For Japan

Stop lever angle_07

Pump speed

r/min

1000

1000

1000

Pressure

kPa

421.5

392

451

Pressure

kgf/cm2

4.3

4

4.6

Remarks

For Japan

For Japan

Stop lever angle_08

Pump speed

r/min

1250

1250

1250

Pressure

kPa

500.5

471

530

Pressure

kgf/cm2

5.1

4.8

5.4

Remarks

For Japan

For Japan

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.3

2.1

2.5

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.3

2

2.6

_03

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.8

3.2

4.4

_04

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.2

2

2.4

Basic

*

Remarks

For Japan

For Japan

_05

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.2

1.9

2.5

Remarks

For Japan

For Japan

_06

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.7

3.1

4.3

Remarks

For Japan

For Japan

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

24

19

29

Control lever angle beta

deg.

44

39

49

Information:

21Apr2010

U-136

A-108

D-119

O-126

TT-9

TM-8

TA-5

Parts stock action only

PRODUCT IMPROVEMENT PROGRAM FOR REMOVING CERTAIN 248-1079, 250-1305, 250-1368, 266-4387, AND 280-0681 FUEL INJECTORS (FOR 3508C, 3512C, AND 3516C ENGINES) FROM DEALER PARTS STOCK

7750 PI70341

When submitting claim for Parts Stock Action, Use the appropriate 99Z as the s/n, the appropriate Service Letter Program Number as the Part number in the Part Causing Failure field, "7751" as the Group Number, "56" as the Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

31Jul2010

PROBLEM

Certain 248-1079, 250-1305, 250-1368, 266-4387, and 280-0681 Fuel Injectors installed in certain 3512C and 3516C engine applications may experience internal body cracks. This condition may result in fuel to oil dilution.

ACTION REQUIRED

Refer to Image1 for Injector Part Numbers and Serial Number Range of affected parts. Refer to Image2 for example of part number (A) and injector serial number identification (B).

Inspect all injector part numbers listed in Image1 to identify if they are within the Serial Number range 1134640 - 1234085.

- If the injector part number listed in Image1 has a serial number that is included in the serial number range 1134640 - 1234085, remove the injector from dealer parts stock.

- If the injector part number listed in Image1 has a serial number that is NOT included in the serial number range 1134640 - 1234085, return the injector to the original packaging, mark the package to indicate the injector has been inspected according to this program (PI7#### / REBE6038), and return the injector to dealer parts stock.

Image1

Image2

SERVICE CLAIM ALLOWANCES

Submit one claim for all parts removed from dealer parts stock.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

A Send-It-Back Parts Return Request will be generated when the claim is submitted with this program (PI7####) as the part causing failure.