Information injection-pump assembly

BOSCH

9 460 611 530

9460611530

ZEXEL

104700-0510

1047000510

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104700-0510 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104600-0510 |

| 3. | NUMBER PLATE | 148636-0800 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1531 |

| 8. | Nozzle and Holder | RF1G 13 H50B |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0111 |

| 11. | NOZZLE | 105007-1370 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 148103-0400 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 148200-0920 | DRIVE SHAFT |

| 12/3. | [1] | 146201-0000 | WOODRUFF KEY |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 148210-0420 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-4820 | CAM PLATE |

| 30. | [1] | 146600-3000 | O-RING |

| 31. | [1] | 146300-1900 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 34. | [1] | 146306-2100 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-3000 | O-RING |

| 37. | [1] | 479765-1320 | TIMER PISTON SENSOR |

| 38. | [2] | 010206-2040 | HEX-SOCKET-HEAD CAP SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0120 | GUIDE PIN |

| 50. | [1] | 146403-8220 | HYDRAULIC HEAD |

| 50. | [1] | 146403-8220 | HYDRAULIC HEAD |

| 50. | [1] | 146403-8220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 123. | [1] | 146620-8800 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-1020 | CAPSULE |

| 130/2. | [1] | 139508-0200 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0300 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-3220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 148120-0020 | OVER FLOW VALVE |

| 137. | [3] | 139512-0500 | GASKET |

| 138. | [1] | 146669-0920 | INLET UNION |

| 158. | [1] | 146614-6900 | SPACER BUSHING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 221. | [1] | 148613-2720 | BRACKET |

| 235. | [1] | 148613-2800 | BRACKET |

| 236. | [2] | 146620-2700 | HEX-SOCKET-HEAD CAP SCREW |

| 236. | [2] | 146620-2700 | HEX-SOCKET-HEAD CAP SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146688-0920 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146669-1020 | INLET UNION |

| 251. | [1] | 020145-1040 | BLEEDER SCREW |

| 275. | [1] | 148612-1120 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 282. | [1] | 139006-4400 | BLEEDER SCREW |

| 317. | [1] | 139006-5700 | BLEEDER SCREW |

| 504/1. | [1] | 146649-4500 | RESISTER |

| 504/1. | [1] | 146649-4600 | RESISTER |

| 504/1. | [1] | 146649-4700 | RESISTER |

| 504/1. | [1] | 146649-4800 | RESISTER |

| 504/1. | [1] | 146649-4900 | RESISTER |

| 504/1. | [1] | 146649-5000 | RESISTER |

| 504/1. | [1] | 146649-5100 | RESISTER |

| 504/1. | [1] | 146649-5200 | RESISTER |

| 504/1. | [1] | 146649-5300 | RESISTER |

| 504/1. | [1] | 146649-5400 | RESISTER |

| 504/1. | [1] | 146649-5500 | RESISTER |

| 504/1. | [1] | 146649-5600 | RESISTER |

| 504/1. | [1] | 146649-5700 | RESISTER |

| 505. | [1] | 148531-2220 | GOVERNOR;ELECTRIC |

| 506. | [3] | 146620-8900 | FLAT-HEAD SCREW |

| 515. | [1] | 106144-1070 | TIMING CONTROL VALVE |

| 515/8. | [1] | 161440-3800 | O-RING |

| 515/9. | [1] | 161440-3700 | O-RING |

| 516. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 531. | [1] | 479765-1020 | PULSE GENERATOR |

| 531/6. | [1] | 479773-6500 | O-RING |

| 800S. | [1] | 148009-0620 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 810S. | [1] | 146600-4620 | REPAIR SET |

| 821S. | [1] | 146210-5820 | ROLLER SET |

| 878S. | [1] | 148600-1300 | SEAL RING |

| 906. | [1] | 148636-0800 | NAMEPLATE |

Include in #2:

104700-0510

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 530

9460611530

ZEXEL

104700-0510

1047000510

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Governor adjustment

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

539.5

510

569

Pump chamber pressure

kgf/cm2

5.5

5.2

5.8

Basic

*

Governor adjustment_02

Pump speed

r/min

100

100

100

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

294

294

Pump chamber pressure

kgf/cm2

3

3

Governor adjustment_03

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

539.5

500

579

Pump chamber pressure

kgf/cm2

5.5

5.1

5.9

Governor adjustment_04

Pump speed

r/min

2250

2250

2250

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

745

696

794

Pump chamber pressure

kgf/cm2

7.6

7.1

8.1

Boost compensator adjustment

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

7

6.8

7.2

Basic

*

Boost compensator adjustment_02

Pump speed

r/min

100

100

100

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

3.5

1.5

5.5

Boost compensator adjustment_03

Pump speed

r/min

360

360

360

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

6.9

4.9

8.9

Boost compensator adjustment_04

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

7

6.7

7.3

Boost compensator adjustment_05

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

70

70

70

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

3.6

1.6

5.6

Boost compensator adjustment_06

Pump speed

r/min

2250

2250

2250

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

9.85

9.3

10.4

Boost compensator adjustment_07

Pump speed

r/min

2250

2250

2250

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

0

0

0

Timer adjustment

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Vtps

V

0.51

0.382

0.638

Basic

*

Timer adjustment_02

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Vtps

V

0.51

0.382

0.638

Timer adjustment_03

Pump speed

r/min

750

750

750

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Vtps

V

1.796

1.591

2.001

Speed control lever angle

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Overflow quantity

cm3/min

510

380

640

0000000901

Pump speed

r/min

1250

1250

1250

U alpha soll + dU alpha soll

V

2.49

2.49

2.49

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

43.1

42.6

43.6

Difference in delivery

mm3/st.

4

Basic

*

_02

Pump speed

r/min

413

413

413

U alpha soll + dU alpha soll

V

1.87

1.87

1.87

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

7.4

4.4

10.4

Difference in delivery

mm3/st.

1.5

Basic

*

Remarks

Confirmation of difference in delivery

Confirmation of difference in delivery

_03

Pump speed

r/min

2600

2600

2600

U alpha soll + dU alpha soll

V

1.82

1.82

1.82

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

14

11.5

16.5

Difference in delivery

mm3/st.

5

Basic

*

Remarks

Confirmation of difference in delivery

Confirmation of difference in delivery

_04

Pump speed

r/min

100

100

100

U alpha soll + dU alpha soll

V

2.76

2.76

2.76

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

31.7

21.7

41.7

_05

Pump speed

r/min

413

413

413

U alpha soll + dU alpha soll

V

1.87

1.87

1.87

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

7.4

4.4

10.4

_06

Pump speed

r/min

450

450

450

U alpha soll + dU alpha soll

V

1.87

1.87

1.87

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

10.2

7.2

13.2

_07

Pump speed

r/min

500

500

500

U alpha soll + dU alpha soll

V

2.47

2.47

2.47

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

40.9

38.4

43.4

_08

Pump speed

r/min

570

570

570

U alpha soll + dU alpha soll

V

1.87

1.87

1.87

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

6.1

3.1

9.1

_09

Pump speed

r/min

1250

1250

1250

U alpha soll + dU alpha soll

V

2

2

2

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

19.2

16.7

21.7

_10

Pump speed

r/min

1250

1250

1250

U alpha soll + dU alpha soll

V

2.49

2.49

2.49

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

43.1

42.1

44.1

_11

Pump speed

r/min

1500

1500

1500

U alpha soll + dU alpha soll

V

2.42

2.42

2.42

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

39.8

37.3

42.3

_12

Pump speed

r/min

1750

1750

1750

U alpha soll + dU alpha soll

V

2.42

2.42

2.42

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

41.3

38.8

43.8

_13

Pump speed

r/min

2250

2250

2250

U alpha soll + dU alpha soll

V

2.43

2.43

2.43

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

40.5

38

43

_14

Pump speed

r/min

2350

2350

2350

U alpha soll + dU alpha soll

V

2.41

2.41

2.41

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

39.2

36.7

41.7

_15

Pump speed

r/min

2600

2600

2600

U alpha soll + dU alpha soll

V

1

1

1

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

3

_16

Pump speed

r/min

2600

2600

2600

U alpha soll + dU alpha soll

V

1.82

1.82

1.82

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

14

11.5

16.5

Stop lever angle

Pump speed

r/min

413

413

413

U alpha soll + dU alpha soll

V

1.87

1.87

1.87

TCV duty (%) F TCV 60Hz

%

0

0

0

Average injection quantity

cm3/min

0

0

0

Stop lever angle_02

Pump speed

r/min

2350

2350

2350

U alpha soll + dU alpha soll

V

2.41

2.41

2.41

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

cm3/min

0

0

0

0000001101

Pump speed

r/min

200

200

200

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Speed output

N=Measure the actual speed. r/min N+-8

N=Measure the actual speed. r/min N+-8

0000001201

Pump speed

r/min

1250

1250

1250

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.49

2.49

2.49

Temperature output

Measure T = actual output temperature degC T+-5

Measure T = actual output temperature degC T+-5

0000001301

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

Pre-stroke

mm

0.1

0.08

0.12

Test data Ex:

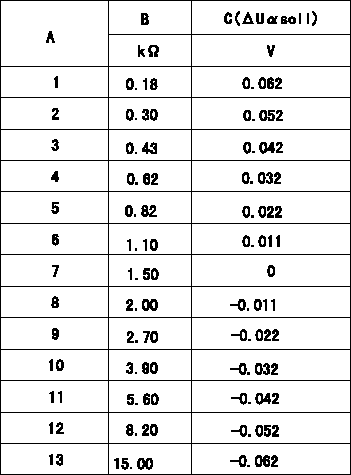

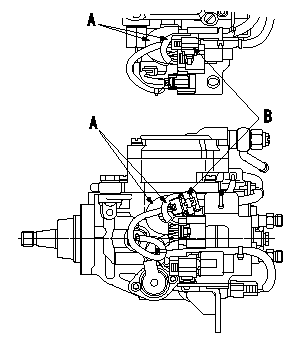

Injection timing adjustment Comp. resistor/voltage

Compensation resistance/compensation voltage comparison

A = Compensation resistor number

B= Compensation resistance

C = Compensation voltage delta U alpha soll

----------

----------

----------

----------

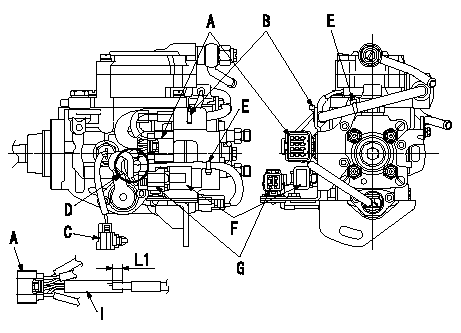

0000001601 HARNESS & CONNECTOR

Connector and binder assembly specification

(1)For A's connector, adjust the position of the protective tube to L1 and install.

(2)After assembling the connector and bushing-type clip, fix the FCV harness and the GE cable using the clip B.

(3)Route the harness at D from the front to the T.P.S., to the Q adjustment and then to the T.C.V. in that order.

(4)At the next step, fix C's P/U connector harness using the clip.

A:GE, FCV, TCV and Q adjustment connectors.

B:Binder

C:Speed pickup connector

E:Push type clip

F:Q adjustment resistor

G:T.P.S. Connector

I:Protective tube

----------

----------

L1=10+-5mm

----------

----------

L1=10+-5mm

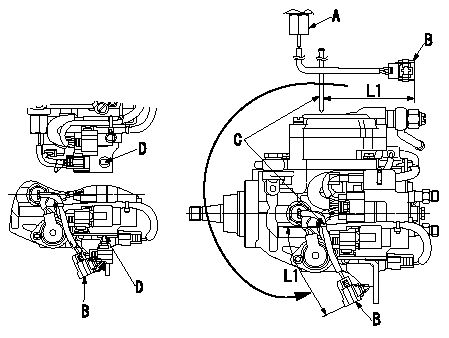

0000001701 HARNESS & CONNECTOR

P/U Harness position specification

Caution: The P/U connector is not fixed to the bracket.

(1)With the clip L1 from end of the connector, gather and fix the P/U and TPS harness.

(2)After fixing the clip, confirm that the P/U connector can be installed to the bracket installation hole. However, do not fix the connector to the bracket.

A:P/U

B:P/U Connector

C:Binder

D:Connector installation bracket hole

----------

----------

L1=(100mm)

----------

----------

L1=(100mm)

0000001801 HARNESS & CONNECTOR

P/U connector temporary fixing specifications

(1)Confirm that the P/U connector can be installed to the bracket's installation hole.

(2)Position the P/U connector and harness between the GE cable and the FCV harness and temporarily fix the connector.

A:Position between the GE cable and the FCV harness.

B:P/U Connector

----------

----------

----------

----------

Information:

General Recommendations and Contamination Control Guidelines for Fuels

Follow all applicable industry standards and all applicable governmental, environmental, and safety guidelines, practices, regulations, and mandates.Note: These general recommendations and guidelines concerning maintenance and care of fuel and fuel storage systems are not intended to be all inclusive. Discuss proper fuel safety and health, handling, and maintenance practices with your fuel supplier. Use of these general recommendations and guidelines does not lessen the engine owners and/or fuel supplier responsibility to follow all industry standard practices for fuel storage and for fuel handling.Note: Where recommendations for draining water and/or sediment and/or debris are stated, dispose of this waste according to all applicable regulations and mandates.Note: Caterpillar filters are designed and built to provide optimal performance and protection of the fuel system components.Clean fuels, as detailed below, are strongly recommended to allow optimal performance and durability of the fuel systems and to reduce power loss, failures, and related down time of engines.Fuels of “ISO 18/16/13” cleanliness levels or cleaner as dispensed into the engine or machine fuel tank should be used. Reduced power, failures and related downtime can result if clean fuels are not used. Fuels of “ISO 18/16/13” are particularly important for new fuel system designs such as Common Rail injection systems and unit injection systems. These new injection system designs utilize higher fuel pressures and are designed with tight clearances between moving parts to meet required stringent emissions regulations. Peak injection pressures in current fuel injection systems may exceed 30,000 psi. Clearances in these systems are less than 5 µm. As a result, particle contaminants as small as 4 µm can cause scoring and scratching of internal pump and injector surfaces and of injector nozzles.Water in the fuel causes cavitation, corrosion of fuel system parts, and provides an environment where microbial growth in the fuel can flourish. Other sources of fuel contamination are soaps, gels, or other compounds that may result from undesirable chemical interactions in the fuels. Gels and other insoluble compounds can also form in biodiesel fuel at low temperatures or if biodiesel is stored for extended periods. An indication of microbial contamination, detrimental fuel additives interactions, or cold temperature gel is very rapid filter plugging of bulk fuel filters or machine fuel filters.To reduce downtime due to contamination, follow these fuel maintenance guidelines in addition to the recommendations given in the "Contamination Control" Chapter in this Special Publication:

Use high-quality fuels per recommended and required specifications (refer to the “Fuel” chapter in this Special Publication).

Do not add new engine oil, waste engine oil or any oil product to the fuel unless the engine is designed and certified to burn diesel engine oil (for example Caterpillar ORS designed for large engines). Engine oils may raise the sulfur level of the fuel and may cause fouling of the fuel system and loss of performance. Engine oils in fuels can also reduce the maintenance intervals of aftertreatment devices in Tier 4 machines.

Use recommended Cat filtration products, including Cat Advanced Efficiency Fuel

Follow all applicable industry standards and all applicable governmental, environmental, and safety guidelines, practices, regulations, and mandates.Note: These general recommendations and guidelines concerning maintenance and care of fuel and fuel storage systems are not intended to be all inclusive. Discuss proper fuel safety and health, handling, and maintenance practices with your fuel supplier. Use of these general recommendations and guidelines does not lessen the engine owners and/or fuel supplier responsibility to follow all industry standard practices for fuel storage and for fuel handling.Note: Where recommendations for draining water and/or sediment and/or debris are stated, dispose of this waste according to all applicable regulations and mandates.Note: Caterpillar filters are designed and built to provide optimal performance and protection of the fuel system components.Clean fuels, as detailed below, are strongly recommended to allow optimal performance and durability of the fuel systems and to reduce power loss, failures, and related down time of engines.Fuels of “ISO 18/16/13” cleanliness levels or cleaner as dispensed into the engine or machine fuel tank should be used. Reduced power, failures and related downtime can result if clean fuels are not used. Fuels of “ISO 18/16/13” are particularly important for new fuel system designs such as Common Rail injection systems and unit injection systems. These new injection system designs utilize higher fuel pressures and are designed with tight clearances between moving parts to meet required stringent emissions regulations. Peak injection pressures in current fuel injection systems may exceed 30,000 psi. Clearances in these systems are less than 5 µm. As a result, particle contaminants as small as 4 µm can cause scoring and scratching of internal pump and injector surfaces and of injector nozzles.Water in the fuel causes cavitation, corrosion of fuel system parts, and provides an environment where microbial growth in the fuel can flourish. Other sources of fuel contamination are soaps, gels, or other compounds that may result from undesirable chemical interactions in the fuels. Gels and other insoluble compounds can also form in biodiesel fuel at low temperatures or if biodiesel is stored for extended periods. An indication of microbial contamination, detrimental fuel additives interactions, or cold temperature gel is very rapid filter plugging of bulk fuel filters or machine fuel filters.To reduce downtime due to contamination, follow these fuel maintenance guidelines in addition to the recommendations given in the "Contamination Control" Chapter in this Special Publication:

Use high-quality fuels per recommended and required specifications (refer to the “Fuel” chapter in this Special Publication).

Do not add new engine oil, waste engine oil or any oil product to the fuel unless the engine is designed and certified to burn diesel engine oil (for example Caterpillar ORS designed for large engines). Engine oils may raise the sulfur level of the fuel and may cause fouling of the fuel system and loss of performance. Engine oils in fuels can also reduce the maintenance intervals of aftertreatment devices in Tier 4 machines.

Use recommended Cat filtration products, including Cat Advanced Efficiency Fuel