Information injection-pump assembly

ZEXEL

104304-4150

1043044150

ISUZU

8941356931

8941356931

Rating:

Cross reference number

ZEXEL

104304-4150

1043044150

ISUZU

8941356931

8941356931

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

22.9

21.9

23.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.7+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8.7

7.7

9.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

9.8

Boost pressure

kPa

16

13.3

17.3

Boost pressure

mmHg

120

100

130

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

10

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Test data Ex:

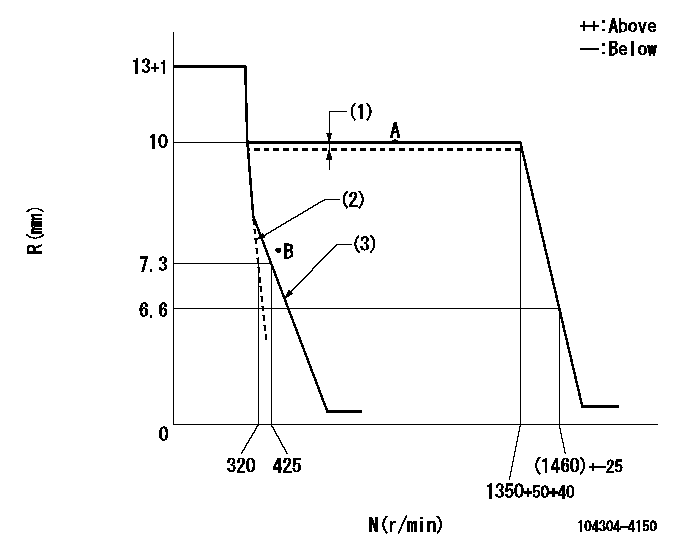

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator stroke: BCL

(2)Set the idle spring.

(3)Main spring setting

----------

BCL=0.2+-0.1mm

----------

----------

BCL=0.2+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=12deg+-3deg b=33deg+-6deg

----------

----------

a=12deg+-3deg b=33deg+-6deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=18deg+-5deg b=(38deg)

----------

----------

a=18deg+-5deg b=(38deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection (same as key groove position)

(3)B.T.D.C.: aa

(4)-

----------

aa=17deg

----------

a=(50deg)

----------

aa=17deg

----------

a=(50deg)

Information:

ACTION REQUIRED

1. Refer to Special Instruction, REHS5023, "Replacing the Fuel Injection Pump on Certain C9.3 Engines". Replace the existing 375-5244 or early production 379-0150 common rail fuel injection pump with the new production 379-0150 common rail fuel injection pump and new gasket 6V-8260. Install a new 356-5214 fuel line from the common rail fuel injection pump to the fuel rail.

2. Refer to C9.3 Disassembly and Assembly, KENR8149 "Engines for Caterpillar Built Machines". Replace the prior 362-0770 Pressure Relief Valve with 415-4991 Pressure Relief Valve, and 228-7102 O-ring.

3. Refer to Service Magazine, SEPD1928, "An Improved Fuel Injection Pump Group Is Used on Certain C9.3 Machine Engines", in order to record the common rail fuel injection pump serial number. This serial number must be entered into the containment service letter claim story.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-5000 hrs,

0-48 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 12.0-hour job for Group 1

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-5000 hrs,

0-48 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 18.0-hour job for Group 2

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 3*******

0-5000 hrs,

0-48 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 15.0-hour job for Group 3

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.