Information injection-pump assembly

BOSCH

9 400 616 503

9400616503

ZEXEL

104304-3200

1043043200

ISHIKAWAJIMA-S

131017150

131017150

Rating:

Cross reference number

BOSCH

9 400 616 503

9400616503

ZEXEL

104304-3200

1043043200

ISHIKAWAJIMA-S

131017150

131017150

Zexel num

Bosch num

Firm num

Name

104304-3200

9 400 616 503

131017150 ISHIKAWAJIMA-S

INJECTION-PUMP ASSEMBLY

T854 * K 14BX PES4K PE

T854 * K 14BX PES4K PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

39.7

38.7

40.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

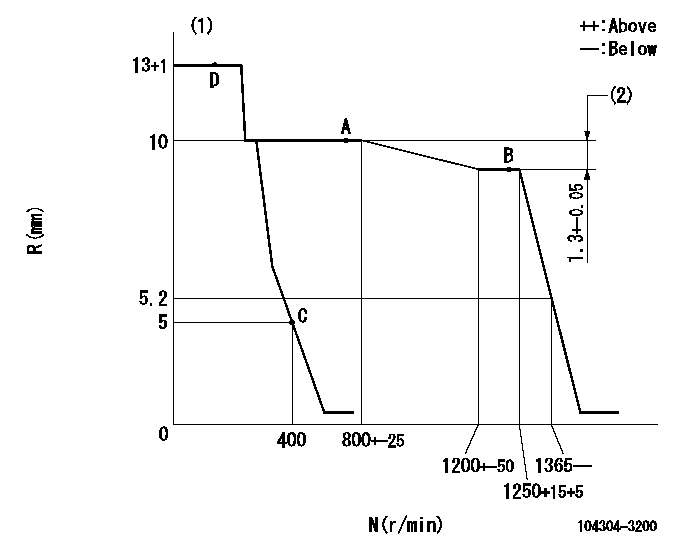

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack difference between N = N1 and N = N2

----------

N1=1250r/min N2=750r/min

----------

----------

N1=1250r/min N2=750r/min

----------

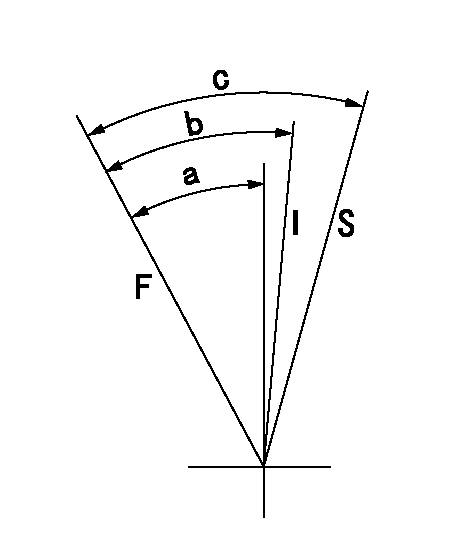

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=21deg+-3deg b=25deg+-6deg c=(35deg)

----------

----------

a=21deg+-3deg b=25deg+-6deg c=(35deg)

Information:

Start By:a. remove valve covers1. Turn the flywheel with Tool (C) until there is clearance between the rocker arms and valve bridges. 2. Engage Tool (A) with the rocker arm, and move Tool (A) against the valve spring force until push rod (1) can be removed.3. Remove the other push rod for the same cylinder. Mark each push rod so it can be installed in its original position. 4. Use Tool (B) to remove valve lifter (2).5. Remove the other valve lifter for the same cylinder. Mark each valve lifter so it can be installed in its original position. 6. Remove spring (3) from lifter (2).7. Inspect spring (3). See Guideline For Reusable Parts, SEBF8066. 8. Identify the location of each valve bridge (4), then remove them.Install Push Rods, Valve Lifters & Valve Bridges

1. Put clean engine oil on each bridge dowel and the bore of each bridge. Install bridges (1) in their original position.2. Use the following procedure to adjust the valve bridges.a. Put clean SAE 30 Engine Oil in the lubrication passage of the bridge.b. Press straight down on the top contact surface of the bridge with a force of 4.45 to 44.50 N (1 to 10 lb).c. Turn the adjusting screw clockwise until the oil film in the lubrication passage of the bridge moves inward.d. Turn the adjusting screw an additional 20 to 30 degrees (1/3 to 1/2 of a flat on the hex nut).e. Hold the adjusting screw in position, and tighten the locknut to a torque of 26 to 34 N m (19 to 25 lb ft).f. Do this procedure for both bridges. Put clean engine oil on the top contact surface of both bridges. 3. Install spring (3) on valve lifter (2). 4. Fasten Tool (A) to valve lifter (2).5. Immerse valve lifter (2) in clean engine oil; then install it in its original position.6. Install the other valve lifter for the same cylinder. 7. Engage Tool (B) with the rocker arm, and move Tool (B) against the valve spring force until push rods (4) can be installed in their original position.8. Use Tool (C) to turn the flywheel so the remaining push rods can be installed. Be sure there is clearance at the rocker arms and valve bridges before compressing the valve pump.9. Check the valve clearance settings. The clearance for the intake valves is 0.38 mm (.015 in). The clearance for the exhaust valve is 0.76 mm (.030 in). See the topic "Valve Clearance Setting" in Testing & Adjusting.End By:a. install valve covers

1. Put clean engine oil on each bridge dowel and the bore of each bridge. Install bridges (1) in their original position.2. Use the following procedure to adjust the valve bridges.a. Put clean SAE 30 Engine Oil in the lubrication passage of the bridge.b. Press straight down on the top contact surface of the bridge with a force of 4.45 to 44.50 N (1 to 10 lb).c. Turn the adjusting screw clockwise until the oil film in the lubrication passage of the bridge moves inward.d. Turn the adjusting screw an additional 20 to 30 degrees (1/3 to 1/2 of a flat on the hex nut).e. Hold the adjusting screw in position, and tighten the locknut to a torque of 26 to 34 N m (19 to 25 lb ft).f. Do this procedure for both bridges. Put clean engine oil on the top contact surface of both bridges. 3. Install spring (3) on valve lifter (2). 4. Fasten Tool (A) to valve lifter (2).5. Immerse valve lifter (2) in clean engine oil; then install it in its original position.6. Install the other valve lifter for the same cylinder. 7. Engage Tool (B) with the rocker arm, and move Tool (B) against the valve spring force until push rods (4) can be installed in their original position.8. Use Tool (C) to turn the flywheel so the remaining push rods can be installed. Be sure there is clearance at the rocker arms and valve bridges before compressing the valve pump.9. Check the valve clearance settings. The clearance for the intake valves is 0.38 mm (.015 in). The clearance for the exhaust valve is 0.76 mm (.030 in). See the topic "Valve Clearance Setting" in Testing & Adjusting.End By:a. install valve covers

Have questions with 104304-3200?

Group cross 104304-3200 ZEXEL

Ishikawajima-S

104304-3200

9 400 616 503

131017150

INJECTION-PUMP ASSEMBLY

T854

T854