Information injection-pump assembly

ZEXEL

104303-5100

1043035100

ISEKI

62156000213E

62156000213e

Rating:

Service parts 104303-5100 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6215300-0022

12.

Open Pre:MPa(Kqf/cm2)

20.6{210}

15.

NOZZLE SET

Include in #1:

104303-5100

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104303-5100

1043035100

ISEKI

62156000213E

62156000213e

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-2

Pre-stroke

mm

2.8

2.75

2.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

30.5

29.5

31.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.4+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6.6

5.6

7.6

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

11+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

49

45

53

Fixing the lever

*

Rack limit

*

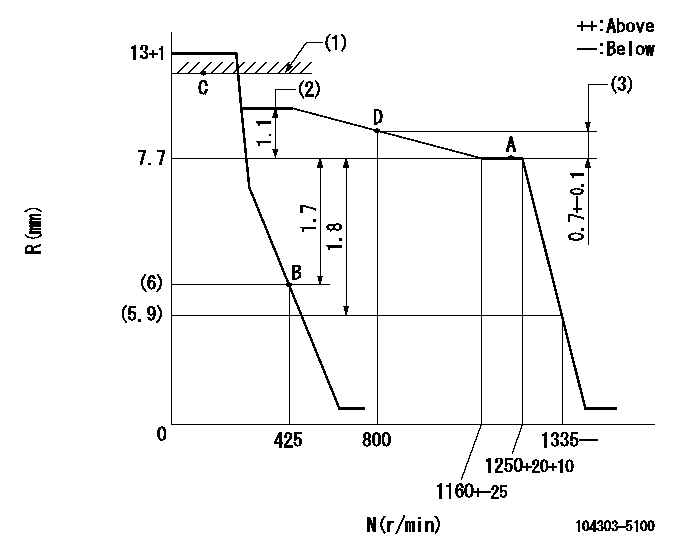

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Torque control stroke

(3)Rack difference between N = N1 and N = N2

----------

N1=1250r/min N2=800r/min

----------

----------

N1=1250r/min N2=800r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-3deg b=21deg+-6deg

----------

----------

a=12deg+-3deg b=21deg+-6deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '00' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(110deg)

----------

aa=18deg

----------

a=(110deg)

Information:

Start By:a. remove vibration damper and pulley 1. Use a punch or Tool (A) to put a hole in seal (1). Use Tool (A) to remove seal (1) from the timing gear cover. When a replacement of the front seal is made, a replacement of the wear sleeve is to be made also. 2. Put Tool (B) in position in the seal bore as shown.3. Install Tool (C) between Tool (B) and the wear sleeve. Turn Tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove Tool (B) and the wear sleeve by hand.Install Crankshaft Front Seal & Wear Sleeve

The wear sleeve and seal must be installed at the same time.1. Install the crankshaft front seal and wear sleeve with Tool (A) as follows: a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V-1541 Quick Cure Primer. Make an application of 9S-3265 Retaining Compound to crankshaft outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the crankshaft.b. Install locator (1) and the bolts on the front of the crankshaft.c. The wear sleeve and seal come as a set with the seal already installed on the wear sleeve. Make sure the lip of the seal is toward the inside of the engine as shown and the outside diameter bevel of the wear sleeve is toward the outside of the engine.d. Put the wear sleeve and seal in position on locator (1). e. Put installer (2) in position on locator (1).f. Put clean engine oil on the face of nut (3) and its contact area on installer (2). Install nut (3) on stud of locator (1).g. Tighten nut (3) until the inside surface of installer (2) comes in contact with locator (1).h. Remove Tool (A) and check the wear sleeve and seal for correct installation.End By:a. install vibration damper and pulley

The wear sleeve and seal must be installed at the same time.1. Install the crankshaft front seal and wear sleeve with Tool (A) as follows: a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V-1541 Quick Cure Primer. Make an application of 9S-3265 Retaining Compound to crankshaft outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the crankshaft.b. Install locator (1) and the bolts on the front of the crankshaft.c. The wear sleeve and seal come as a set with the seal already installed on the wear sleeve. Make sure the lip of the seal is toward the inside of the engine as shown and the outside diameter bevel of the wear sleeve is toward the outside of the engine.d. Put the wear sleeve and seal in position on locator (1). e. Put installer (2) in position on locator (1).f. Put clean engine oil on the face of nut (3) and its contact area on installer (2). Install nut (3) on stud of locator (1).g. Tighten nut (3) until the inside surface of installer (2) comes in contact with locator (1).h. Remove Tool (A) and check the wear sleeve and seal for correct installation.End By:a. install vibration damper and pulley