Information injection-pump assembly

BOSCH

9 400 616 476

9400616476

ZEXEL

104303-3530

1043033530

ISEKI

62156000860

62156000860

Rating:

Service parts 104303-3530 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104303-3530

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 476

9400616476

ZEXEL

104303-3530

1043033530

ISEKI

62156000860

62156000860

Zexel num

Bosch num

Firm num

Name

104303-3530

9 400 616 476

62156000860 ISEKI

INJECTION-PUMP ASSEMBLY

E3AD1 * K

E3AD1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.1

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

33.2

32.2

34.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

5.9+-0.5

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

13+1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

36

36

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the idle spring.

(2)Main spring setting

(3)Rack difference from N = N1

(4)Rack difference between N = N2 and N = N3

----------

N1=1200r/min N2=1200r/min N3=400r/min

----------

----------

N1=1200r/min N2=1200r/min N3=400r/min

----------

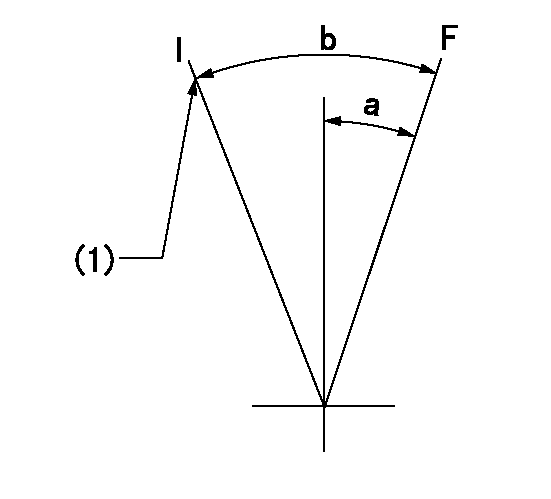

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=15deg+-3deg b=24deg+-6deg

----------

----------

a=15deg+-3deg b=24deg+-6deg

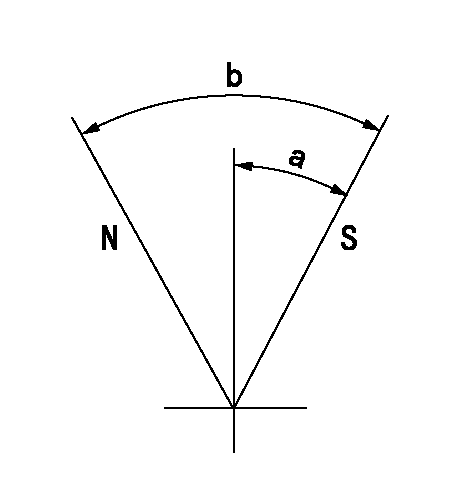

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10deg+-1deg b=(38deg)

----------

----------

a=10deg+-1deg b=(38deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(120deg)

----------

aa=18deg

----------

a=(120deg)

Information:

3306 Engine Shown1. Turn the fuel supply line valve to the "OFF" position.2. Remove the clamp that holds fuel drain line (1) to the fuel transfer pump. Remove fuel lines (4) and (5).3. Remove bolts (2) and fuel transfer pump (3) from the fuel injection pump housing. Remove the O-ring seal from the fuel transfer pump if necessary.4. Make sure the O-ring seal is in position on the fuel transfer pump. Put the fuel transfer pump in position on the fuel injection pump housing. Install bolts (2) that hold the fuel transfer pump to the fuel injection pump housing.5. Install the clamp that holds fuel drain line (1) to the fuel transfer pump. Install fuel line (4) between the fuel transfer pump and the fuel filter base. Install fuel line (5) between the fuel transfer pump and the fuel priming pump.6. Turn the fuel supply line valve to the "ON" position.Disassemble Fuel Transfer Pump

Start By:a. remove fuel transfer pump

Cover (1) is under spring force. To prevent possible personal injury, carefully remove bolts (2) and cover (1).

1. Remove bolts (2) and cover (1) from the housing. 2. Remove O-ring seals (3) and (4) from the cover.3. Remove valve assembly (5) from the cover. 4. Remove spring (6) from the housing. 5. Remove piston (12) from sleeve (10). Remove washer (15), valve assembly (14) and seal (13) from piston (12).6. Remove sleeve (10) from housing (7). Remove O-ring seal (11) from the sleeve.7. Remove guide and tappet assembly (9) and seal (8) from housing (7). 8. Remove two screws (16), cover (17) and the seal from housing (7). 9. Remove valve assembly (18) from housing (7).Assemble Fuel Transfer Pump

Be sure all parts of the fuel transfer pump are clean before assembly.

1. Install valve assembly (2) in housing (1) as shown. 2. Put clean diesel fuel on seal (2). Put seal (3) in position on cover (4) as shown. Put cover (4) on housing (1). Install the screws that hold the cover. 3. Put clean diesel fuel on seal (5). Put seal (5) and guide and tappet assembly (6) in position in housing (1).4. Put clean diesel fuel on O-ring seal (8). Put O-ring seal (8) in position on sleeve (7). Install sleeve (7) in housing (1).5. Install piston (9) in sleeve (7).6. Put clean diesel fuel on seal (10). Put seal (10), valve assembly (11) and washer (12) in position in piston (7). 7. Put clean diesel fuel on O-ring seals (13) and (14). Put the O-ring seals and valve assembly (15) in position in cover (16) as shown. 8. Put spring (17) and cover (16) in position on housing (1). Install the bolts that hold the spring and cover.End By:a. install fuel transfer pump

Have questions with 104303-3530?

Group cross 104303-3530 ZEXEL

Iseki

104303-3530

9 400 616 476

62156000860

INJECTION-PUMP ASSEMBLY

E3AD1

E3AD1