Information injection-pump assembly

ZEXEL

104303-2550

1043032550

ISEKI

62156000100

62156000100

Rating:

Service parts 104303-2550 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6515300-1100E

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104303-2550

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104303-2550

1043032550

ISEKI

62156000100

62156000100

Zexel num

Bosch num

Firm num

Name

104303-2550

62156000100 ISEKI

INJECTION-PUMP ASSEMBLY

E3AE1 * K

E3AE1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-2

Pre-stroke

mm

2.1

2.05

2.15

Rack position

R=9.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.2

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

25.9

24.9

26.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.2+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6.4

5.4

7.4

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.4+-0.5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

25.5

24.5

26.5

Basic

*

Fixing the lever

*

Remarks

Set full load.

Set full load.

Test data Ex:

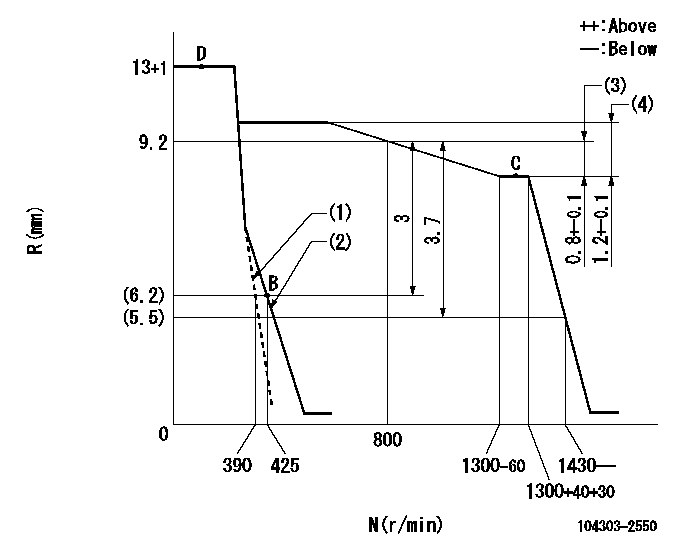

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the idle spring.

(2)Main spring setting

(3)Rack difference between N = N1 and N = N2

(4)Rack difference between N = N3 and N = N4

----------

N1=1300r/min N2=800r/min N3=500r/min N4=1300r/min

----------

----------

N1=1300r/min N2=800r/min N3=500r/min N4=1300r/min

----------

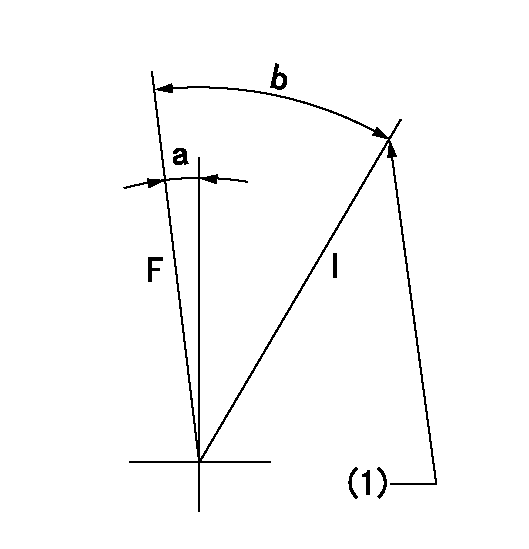

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-3deg b=31deg+-6deg

----------

----------

a=7deg+-3deg b=31deg+-6deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '00' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(110deg)

----------

aa=20deg

----------

a=(110deg)

Information:

Delco-Remy Alternator

(1) Regulator. (2) Roller bearing. (3) Stator winding. (4) Ball bearing. (5) Rectifier bridge. (6) Field winding. (7) Rotor assembly. (8) Fan.Alternator (Bosch)

The alternator is driven by V-belts from the crankshaft pulley. This alternator is a three phase, self-rectifying charging unit. The regulator is part of the alternator.

Bosch Alternator

(1) Fan. (2) Stator winding. (3) Field winding. (4) Regulator. (5) Ball bearing. (6) Roller bearing. (7) Rotor. (8) Rectifier assembly.This alternator design has no need for slip rings or brushes, and the only part that has movement is the rotor assembly. All conductors that carry current are stationary. The conductors are: the field winding, stator windings, six rectifying diodes, and the regulator circuit components.The rotor assembly has many magnetic poles like fingers with air space between each opposite pole. The poles have residual magnetism (like permanent magnets) that produce a small amount of magnet-like lines of force (magnetic field) between the poles. As the rotor assembly begins to turn between the field winding and the stator windings, a small amount of alternating current (AC) is produced in the stator windings from the small magnetic lines of force made by the residual magnetism of the poles. This AC current is changed to direct current (DC) when it passes through the diodes of the rectifier bridge. Most of this current goes to charge the battery and to supply the low amperage circuit, and the remainder is sent to the field windings. The DC current flow through the field windings (wires around an iron core) now increases the strength of the magnetic lines of force. These stronger lines of force now increase the amount of AC current produced in the stator windings. The increased speed of the rotor assembly also increases the current and voltage output of the alternator.The voltage regulator is a solid state (transistor, stationary parts) electronic switch. It feels the voltage in the system and switches on and off many times a second to control the field current (DC current to the field windings) for the alternator to make the needed voltage output.Alternator (Nippondenso)

The alternator is driven by a V-belt from the crankshaft pulley. The only part in the alternator which has movement is rotor assembly (9). Rotor assembly (9) is held in position by a ball bearing at each end of rotor shaft (8).The alternator is made up of a frame (3) on the drive end, rotor assembly (9), stator assembly (5), rectifier assembly (11), brushes (7) and holder assembly, slip rings (13), rear end frame (12) and regulator (6). Drive pulley (1) has a fan (2) for heat removal by the movement of air through the alternator.

Alternator Schematic (With Regulator Attached)

(1) Pulley. (2) Fan. (3) Drive end frame. (4) Stator coils. (5) Stator assembly. (6) Regulator. (7) Brushes. (8) Rotor shaft. (9) Rotor assembly. (10) Field windings. (11) Rectifier assembly. (12) Rear end frame. (13) Slip rings.Rotor assembly (9) has field windings (10) (wires around an iron core) which make magnetic lines of force when direct

Have questions with 104303-2550?

Group cross 104303-2550 ZEXEL

Ishikawajima-S

Nissan-Diesel

Iseki

104303-2550

62156000100

INJECTION-PUMP ASSEMBLY

E3AE1

E3AE1