Information injection-pump assembly

ZEXEL

104303-2080

1043032080

ISUZU

5156011622

5156011622

Rating:

Service parts 104303-2080 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-110-2

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104303-2080

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104303-2080

1043032080

ISUZU

5156011622

5156011622

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

28.4

27.4

29.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.1+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

6.5

5.5

7.5

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

13+1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

37

37

Fixing the lever

*

Test data Ex:

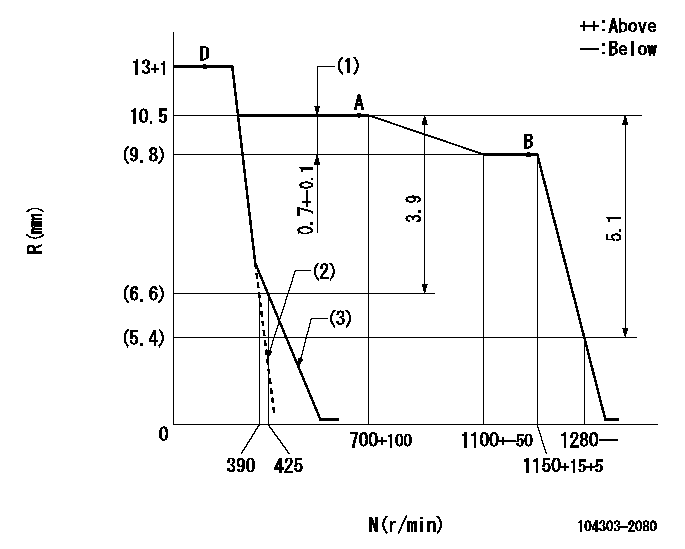

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack difference between N = N1 and N = N2

(2)Set the idle spring.

(3)Main spring setting

----------

N1=700r/min N2=1150r/min

----------

----------

N1=700r/min N2=1150r/min

----------

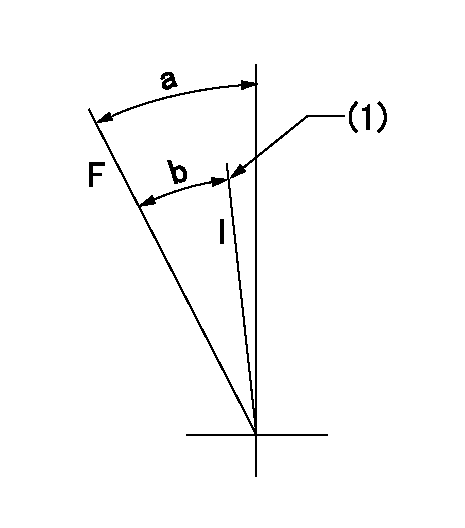

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=36deg+-3deg b=26deg+-6deg

----------

----------

a=36deg+-3deg b=26deg+-6deg

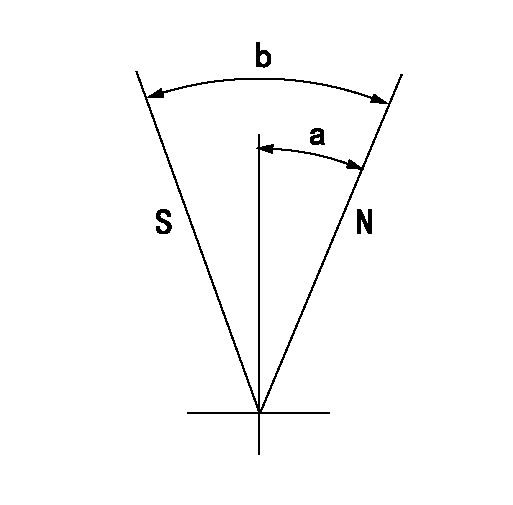

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=18deg+-5deg b=(38deg)

----------

----------

a=18deg+-5deg b=(38deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '00' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(110deg)

----------

aa=16deg

----------

a=(110deg)

Information:

This screen will be displayed when the coolant temperature is below 0 degrees Celsius (0°C). This screen will be displayed when the coolant temperature is above 64 degrees Celsius (64°C).Fault Displays

This screen will be displayed if an internal fault is found.Refer to Service in this manual to return the DDT. This screen will be displayed if an internal fault is found.Refer to Troubleshooting the DDT in this manual. This screen will be displayed if the DDT is unable to talk (communicate) to the Electronic Control Module.Refer to Troubleshooting the DDT in this manual. This screen will be displayed if the Customer Passwords are requested and the passwords entered are found to be invalid. This screen will be displayed if the an engine rating function is selected and the engine is running. This screen will be displayed if the keypad is found to be faulty.Refer to Service in this manual to return the DDT. This screen will be displayed if a number is entered into the DDT for direct access to a nonexisting Mode or Function.Fault Code Translation Chart

Challenger 3176 EUI Fault Code Translation Chart

Mode/Function Chart

Troubleshooting the DDT

LCD display is blank:* Disconnect and reconnect T-harness cable or* Replace T-harness cable or* Service is required LCD display top line is black and bottom line is blank:* Disconnect and reconnect T-harness cable or* Remove and install the Service Program Module or* Service is required LCD display bottom line shows ' FAULT #E0':* Service is required LCD display bottom line shows ' FAULT #E1':* Remove and install the Service Program Module or* Service is required LCD display bottom line shows ' FAULT #E2':* Press CLEAR key to clear fault condition or* Disconnect and reconnect T-harness cable or* Check for power ON at the Electronic Control Module LCD display bottom line shows ' FAULT #E3':* Press CLEAR key to clear fault condition* Press ALT1 key* Reenter customer passwords LCD display bottom line shows ' FAULT #E4':* Turn engine OFF but leave power ON at the electronic control module* Press CLEAR key to clear fault condition LCD display bottom line shows ' SERVICE, KEYPAD':* Service is required LCD display bottom line shows ' Not received':* Abnormal, no fault message have been received LCD display bottom line shows ' NO FAULTS':* Normal, no faults have been received LCD display bottom line shows ' CONNECT 3176 ECM':* Connect the DDT to the correct Electronic Control Module LCD display bottom line shows ' UPDATE ECM':* Warning, the electronic control module that is connected to the DDT is not current. LCD display bottom line shows ' UPDATE DDT':* Warning, the DDTs service program module is not current LCD display bottom line shows ' NO SIGNAL' when a modulated signal is expected:* Disconnect and reconnect probe LCD display bottom line shows ' FREQ TOO LO':* Disconnect and reconnect probe LCD display bottom line shows ' FREQ TOO HI':* Disconnect and reconnect probe LCD display bottom line

This screen will be displayed if an internal fault is found.Refer to Service in this manual to return the DDT. This screen will be displayed if an internal fault is found.Refer to Troubleshooting the DDT in this manual. This screen will be displayed if the DDT is unable to talk (communicate) to the Electronic Control Module.Refer to Troubleshooting the DDT in this manual. This screen will be displayed if the Customer Passwords are requested and the passwords entered are found to be invalid. This screen will be displayed if the an engine rating function is selected and the engine is running. This screen will be displayed if the keypad is found to be faulty.Refer to Service in this manual to return the DDT. This screen will be displayed if a number is entered into the DDT for direct access to a nonexisting Mode or Function.Fault Code Translation Chart

Challenger 3176 EUI Fault Code Translation Chart

Mode/Function Chart

Troubleshooting the DDT

LCD display is blank:* Disconnect and reconnect T-harness cable or* Replace T-harness cable or* Service is required LCD display top line is black and bottom line is blank:* Disconnect and reconnect T-harness cable or* Remove and install the Service Program Module or* Service is required LCD display bottom line shows ' FAULT #E0':* Service is required LCD display bottom line shows ' FAULT #E1':* Remove and install the Service Program Module or* Service is required LCD display bottom line shows ' FAULT #E2':* Press CLEAR key to clear fault condition or* Disconnect and reconnect T-harness cable or* Check for power ON at the Electronic Control Module LCD display bottom line shows ' FAULT #E3':* Press CLEAR key to clear fault condition* Press ALT1 key* Reenter customer passwords LCD display bottom line shows ' FAULT #E4':* Turn engine OFF but leave power ON at the electronic control module* Press CLEAR key to clear fault condition LCD display bottom line shows ' SERVICE, KEYPAD':* Service is required LCD display bottom line shows ' Not received':* Abnormal, no fault message have been received LCD display bottom line shows ' NO FAULTS':* Normal, no faults have been received LCD display bottom line shows ' CONNECT 3176 ECM':* Connect the DDT to the correct Electronic Control Module LCD display bottom line shows ' UPDATE ECM':* Warning, the electronic control module that is connected to the DDT is not current. LCD display bottom line shows ' UPDATE DDT':* Warning, the DDTs service program module is not current LCD display bottom line shows ' NO SIGNAL' when a modulated signal is expected:* Disconnect and reconnect probe LCD display bottom line shows ' FREQ TOO LO':* Disconnect and reconnect probe LCD display bottom line shows ' FREQ TOO HI':* Disconnect and reconnect probe LCD display bottom line