Information injection-pump assembly

BOSCH

9 400 616 425

9400616425

ZEXEL

104303-1000

1043031000

Rating:

Service parts 104303-1000 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104303-1000

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 425

9400616425

ZEXEL

104303-1000

1043031000

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

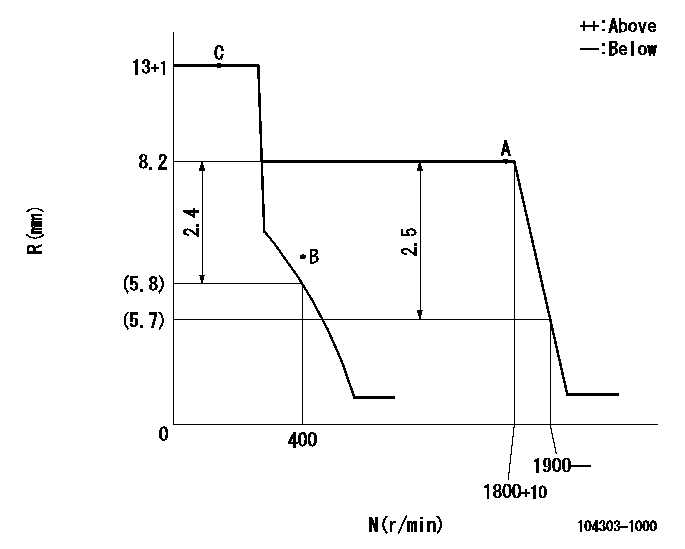

Injection quantity adjustment

Adjusting point

A

Rack position

8.2

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

19.6

18.6

20.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-13

13

Fixing the lever

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

13+1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

28

28

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

----------

----------

----------

----------

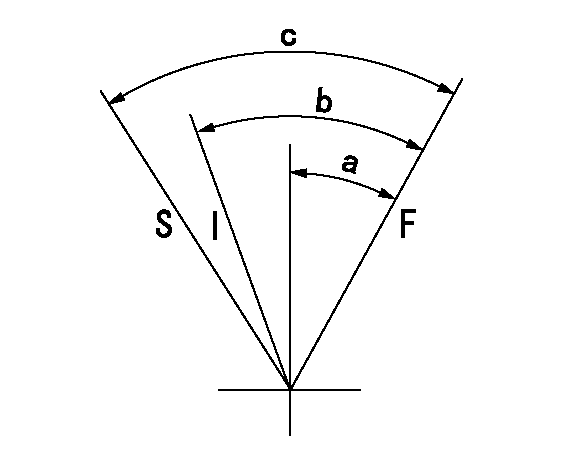

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=20deg+-3deg b=34deg+-6deg c=47deg+-6deg

----------

----------

a=20deg+-3deg b=34deg+-6deg c=47deg+-6deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Jacket Water Pump

A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Visually inspect the water pump for leaks. If leaking is observed, replace all seals. Refer to the Service Manual for the procedure to replace the seals.Turbocharger

Refer to the Turbocharger topic in the Every 3000 Hours maintenance interval for information regarding turbocharger inspection. Refer to the Service Manual, or consult with your Caterpillar dealer for the complete turbocharger inspection procedure.Alternator and Starting Motor

Caterpillar recommends a scheduled inspection of the alternator. Inspect the alternator for loose connections and proper battery charging. Inspect the ammeter gauge during engine operation to ensure the batteries and/or electrical system is performing correctly. Make repairs as necessary. Refer to the Service Manual.Check the alternator and battery charger for proper operation. If the batteries are properly charged, ammeter reading should be very near zero. All batteries should be kept charged. The batteries should be kept warm because temperature affects the cranking power. If the battery is too cold, it will not crank the engine, even if the engine is warm.When the engine is not run for long periods of time or run for short periods, the batteries may not fully recharge. Ensure the alternator performs properly to charge the battery and to help prevent the battery from freezing.If the starting motor fails, the engine may not start in an emergency situation. Caterpillar recommends a schedule inspection/check of your starting motor. The starting motor should be checked for correct operation. All electrical connections should be cleaned and checked. Refer to the established procedure for inspection and specifications in the Service Manual, or contact your Caterpillar dealer for assistance.Repair Before Failure

Until recently, engine maintenance and repair management involved changing the oil when it was convenient and repairing the engine when it was damaged. This seemed to be the accepted way of managing a maintenance operation.However, due to a variety of circumstances, increasing competition have caused users to look for ways to prolong equipment life and lower operating costs so that they could be competitive.To assist Caterpillar engine users in prolonging engine life and reducing operating costs, the Value Planned Repair approach to engine maintenance was developed.The Value Planned Repair approach can be tailored for any engine. This approach, when properly structured, outlines every maintenance and repair service required to support an engine from the day it enters service until the day it is retired.To ensure the repair is performed efficiently and expediently, the Value Planned Repair concept approaches a given repair in three basis steps:1. Repair determination2. Evaluation of repair options3. Selection of the most appropriate optionThe Value Planned Repair approach addresses:* Services required to maintain an engine at optimum efficiency.* Scheduled maintenance, repairs and overhauls to minimize unscheduled downtime.* Preplanned repairs and overhauls that can be flat-rated, putting you in charge of costs.* Repair

A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Visually inspect the water pump for leaks. If leaking is observed, replace all seals. Refer to the Service Manual for the procedure to replace the seals.Turbocharger

Refer to the Turbocharger topic in the Every 3000 Hours maintenance interval for information regarding turbocharger inspection. Refer to the Service Manual, or consult with your Caterpillar dealer for the complete turbocharger inspection procedure.Alternator and Starting Motor

Caterpillar recommends a scheduled inspection of the alternator. Inspect the alternator for loose connections and proper battery charging. Inspect the ammeter gauge during engine operation to ensure the batteries and/or electrical system is performing correctly. Make repairs as necessary. Refer to the Service Manual.Check the alternator and battery charger for proper operation. If the batteries are properly charged, ammeter reading should be very near zero. All batteries should be kept charged. The batteries should be kept warm because temperature affects the cranking power. If the battery is too cold, it will not crank the engine, even if the engine is warm.When the engine is not run for long periods of time or run for short periods, the batteries may not fully recharge. Ensure the alternator performs properly to charge the battery and to help prevent the battery from freezing.If the starting motor fails, the engine may not start in an emergency situation. Caterpillar recommends a schedule inspection/check of your starting motor. The starting motor should be checked for correct operation. All electrical connections should be cleaned and checked. Refer to the established procedure for inspection and specifications in the Service Manual, or contact your Caterpillar dealer for assistance.Repair Before Failure

Until recently, engine maintenance and repair management involved changing the oil when it was convenient and repairing the engine when it was damaged. This seemed to be the accepted way of managing a maintenance operation.However, due to a variety of circumstances, increasing competition have caused users to look for ways to prolong equipment life and lower operating costs so that they could be competitive.To assist Caterpillar engine users in prolonging engine life and reducing operating costs, the Value Planned Repair approach to engine maintenance was developed.The Value Planned Repair approach can be tailored for any engine. This approach, when properly structured, outlines every maintenance and repair service required to support an engine from the day it enters service until the day it is retired.To ensure the repair is performed efficiently and expediently, the Value Planned Repair concept approaches a given repair in three basis steps:1. Repair determination2. Evaluation of repair options3. Selection of the most appropriate optionThe Value Planned Repair approach addresses:* Services required to maintain an engine at optimum efficiency.* Scheduled maintenance, repairs and overhauls to minimize unscheduled downtime.* Preplanned repairs and overhauls that can be flat-rated, putting you in charge of costs.* Repair