Information injection-pump assembly

ZEXEL

104302-6610

1043026610

TOYO-SHA

5301510102

5301510102

Rating:

Service parts 104302-6610 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104302-6610

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104302-6610

1043026610

TOYO-SHA

5301510102

5301510102

Zexel num

Bosch num

Firm num

Name

104302-6610

5301510102 TOYO-SHA

INJECTION-PUMP ASSEMBLY

2S100 *

2S100 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

2.4

2.35

2.45

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

31.7

30.7

32.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.4+-0.5

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

33.7

32.7

34.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

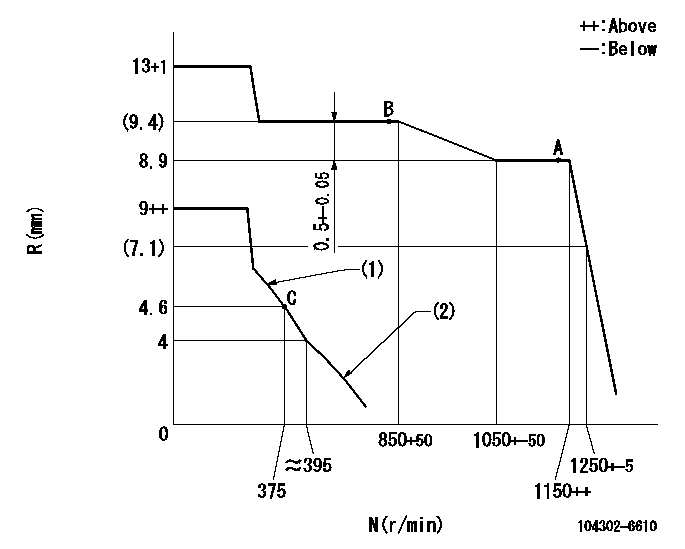

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the idle spring.

(2)Set the governor spring.

----------

----------

----------

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-6deg b=16deg+-3deg

----------

----------

a=19deg+-6deg b=16deg+-3deg

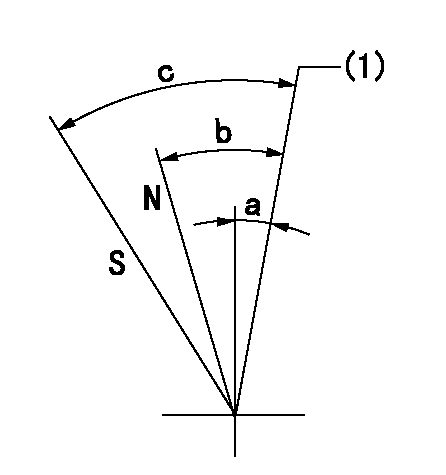

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At lever installation

----------

----------

a=5deg+-3deg b=18deg+-3deg c=(38deg)

----------

----------

a=5deg+-3deg b=18deg+-3deg c=(38deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa (at starting)

(4)-

----------

aa=13.5deg

----------

a=(40deg)

----------

aa=13.5deg

----------

a=(40deg)

Information:

Air Shutoff Solenoid (If Equipped)

This optional solenoid is located on top of the engine in the air inlet system. When the solenoid is activated, the solenoid mechanically shuts off inlet air to the engine. The solenoid can only be activated by the overspeed switch or the emergency stop switch.Fuel Shutoff Solenoid

This solenoid is located on the governor or on the fuel injection pump. When the solenoid is activated, the solenoid moves the fuel rack (either directly or through the governor) to the Fuel Off position.Overspeed Shutoffs

Magnetic pickup (1), mounted in the flywheel housing (2).A magnetic pickup mounted in the flywheel housing senses the passage of the flywheel ring gear teeth. Should the engine speed increase above the overspeed setting of the Electronic Speed Switch (118 percent of rated engine speed), the magnetic pickup will sense the overspeed. The overspeed condition activates both the air (if equipped) and fuel shutoff solenoids.The shutoffs must be reset before the engine will restart. A reset button on the Electronic Speed Switch (in the junction box) must be pushed to open the overspeed switch. The air shutoff lever (at the top of the air inlet housing) must be manually reset.If equipped with a Caterpillar Generator Set Control Panel, the devices on the panel must be reset after an overspeed shutoff. Turn the Engine Control Switch to the OFF/RESET position.Oil Pressure Switches

Typical example of oil pressure switches, mounted in the rear of the junction box.An oil pressure switch has wires connected to the electrical system for alarm or shutoff functions. The oil pressure switch senses oil pressure at the bearing oil gallery. If sufficient oil pressure is not achieved after engine starting, or if the engine has been running normally and then loses oil pressure, the fuel shutoff solenoid is energized to shut the engine off. No resetting procedure is required.Engine Step Oil Pressure

This is an adjustable engine speed setting that protects the engine from a failure caused by too little oil pressure for a specified speed range. This option requires two different oil pressure switches. One switch has a high pressure rating- when the engine is running above the speed setting, the engine must maintain oil pressure higher than the switch rating. The other switch has a low pressure rating- an engine running below the speed setting must maintain oil pressure above the low switch rating.In an automatic start/stop system, an automatic reset switch is used. Manually operated systems require the switch to be reset before the engine will start.

If the RESET button does not move to the extended position after the engine starts, the engine will NOT be protected by this particular switch.If the RESET button remains in the reset position, the engine oil pump will not develop normal oil pressure. An inspection should be made to correct the problem.

In order to reset the switch, push the RESET button until the button latches. After the engine starts and develops oil pressure, the button will move to the extended (running) position.

The button must

This optional solenoid is located on top of the engine in the air inlet system. When the solenoid is activated, the solenoid mechanically shuts off inlet air to the engine. The solenoid can only be activated by the overspeed switch or the emergency stop switch.Fuel Shutoff Solenoid

This solenoid is located on the governor or on the fuel injection pump. When the solenoid is activated, the solenoid moves the fuel rack (either directly or through the governor) to the Fuel Off position.Overspeed Shutoffs

Magnetic pickup (1), mounted in the flywheel housing (2).A magnetic pickup mounted in the flywheel housing senses the passage of the flywheel ring gear teeth. Should the engine speed increase above the overspeed setting of the Electronic Speed Switch (118 percent of rated engine speed), the magnetic pickup will sense the overspeed. The overspeed condition activates both the air (if equipped) and fuel shutoff solenoids.The shutoffs must be reset before the engine will restart. A reset button on the Electronic Speed Switch (in the junction box) must be pushed to open the overspeed switch. The air shutoff lever (at the top of the air inlet housing) must be manually reset.If equipped with a Caterpillar Generator Set Control Panel, the devices on the panel must be reset after an overspeed shutoff. Turn the Engine Control Switch to the OFF/RESET position.Oil Pressure Switches

Typical example of oil pressure switches, mounted in the rear of the junction box.An oil pressure switch has wires connected to the electrical system for alarm or shutoff functions. The oil pressure switch senses oil pressure at the bearing oil gallery. If sufficient oil pressure is not achieved after engine starting, or if the engine has been running normally and then loses oil pressure, the fuel shutoff solenoid is energized to shut the engine off. No resetting procedure is required.Engine Step Oil Pressure

This is an adjustable engine speed setting that protects the engine from a failure caused by too little oil pressure for a specified speed range. This option requires two different oil pressure switches. One switch has a high pressure rating- when the engine is running above the speed setting, the engine must maintain oil pressure higher than the switch rating. The other switch has a low pressure rating- an engine running below the speed setting must maintain oil pressure above the low switch rating.In an automatic start/stop system, an automatic reset switch is used. Manually operated systems require the switch to be reset before the engine will start.

If the RESET button does not move to the extended position after the engine starts, the engine will NOT be protected by this particular switch.If the RESET button remains in the reset position, the engine oil pump will not develop normal oil pressure. An inspection should be made to correct the problem.

In order to reset the switch, push the RESET button until the button latches. After the engine starts and develops oil pressure, the button will move to the extended (running) position.

The button must

Have questions with 104302-6610?

Group cross 104302-6610 ZEXEL

Toyo-Sha

104302-6610

5301510102

INJECTION-PUMP ASSEMBLY

2S100

2S100