Information injection-pump assembly

BOSCH

9 400 616 421

9400616421

ZEXEL

104302-6600

1043026600

TOYO-SHA

5601510102

5601510102

Rating:

Service parts 104302-6600 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104302-6600

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 421

9400616421

ZEXEL

104302-6600

1043026600

TOYO-SHA

5601510102

5601510102

Zexel num

Bosch num

Firm num

Name

104302-6600

9 400 616 421

5601510102 TOYO-SHA

INJECTION-PUMP ASSEMBLY

2S107 K 14BT INJECTION PUMP ASSY PES2K PE

2S107 K 14BT INJECTION PUMP ASSY PES2K PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

2.4

2.35

2.45

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

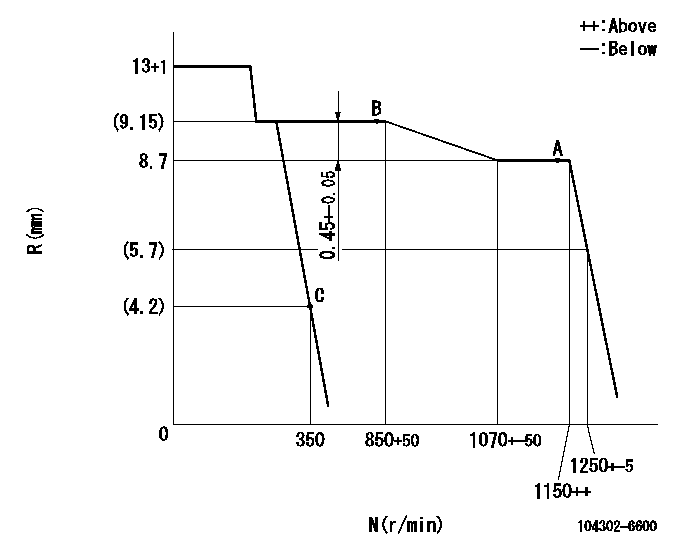

Injection quantity adjustment

Adjusting point

A

Rack position

8.7

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

35.5

34.5

36.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.15

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

37

36

38

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.2+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12.6

11.6

13.6

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

----------

----------

----------

----------

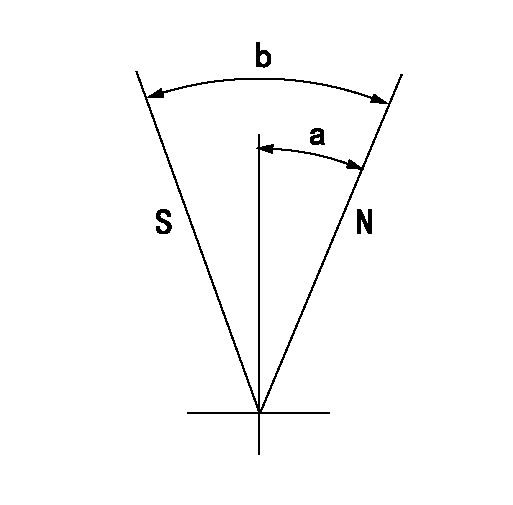

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-6deg b=16deg+-3deg

----------

----------

a=19deg+-6deg b=16deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=18deg+-3deg b=(38deg)

----------

----------

a=18deg+-3deg b=(38deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa (at starting)

(4)-

----------

aa=12.5deg

----------

a=(40deg)

----------

aa=12.5deg

----------

a=(40deg)

Information:

Display

The upper display (1) and lower display (2) of the GSC provide information about the generator set.* The upper display (1) shows AC voltage, current, and frequency of one phase of the generator output. Each phase can be viewed one at a time by pushing phase select key (4). The upper display (1) is also used to show the various fault codes for system faults. For more information on fault codes, refer to the Service Manual Module SENR5809 for Fault Descriptions.* The lower display (2) shows: system battery voltage, engine hours, engine speed, engine oil pressure, and engine coolant temperature. The value for one of those conditions is displayed for two seconds, then the display scrolls to the value for the next condition. A small pointer identifies the engine condition that corresponds to the value that is showing. When engine meter key (3) is pressed, the lower display stops scrolling and continuously shows one particular value. The pointer flashes above the condition whose value is showing. When the engine meter key is pressed a second time, the display returns to scrolling.* The lower display also shows a relay status indicator. When a GSC relay is activated, the corresponding relay indicator (K1, K2, etc.) is shown on lower display (2). When a relay is not activated, the corresponding indicator (K1, K2, etc.) is not shown. Refer to the Service Manual Module SENR5809 for a description of the relay functions.Both the upper and lower display are used for programming functions when in the service mode. For more information, refer to the Service Manual Module SENR5809 for Service Modes.Keypad

The keypad (3) is used to control the information that is shown on upper display (1) and the lower display (2). The seven keys of keypad have two sets of functions: normal functions and service functions. For a description of the service functions of the keys, refer to the Service Manual Module SENR5809 for Service Models. The normal functions of the keys are as follows. Leftmost key (5) - This key only functions when the GSC is in the service mode. This key is used to scroll right. PHASE SELECT key (6) - This key selects which phase of the generator output shows on the GSC upper display. Pressing this key allows the operator to check the voltage, current, and frequency of each phase, one at a time. ENGINE METER key (7) - This key stops the scrolling of engine conditions on the lower display (2). The lower display continuously shows the value for one particular engine condition. The pointer for the particular engine condition flashes to indicate scrolling is stopped. Pressing the key again resumes the scrolling. LAMP TEST key (8) - This key perfumes a lamp test on the GSC and the optional alarm module for a maximum of ten seconds, if held pressed. On the GSC: the eight fault indicators are ON CONTINUOUSLY - every segment of the upper display (1) and the lower display (2) are ON. For the

The upper display (1) and lower display (2) of the GSC provide information about the generator set.* The upper display (1) shows AC voltage, current, and frequency of one phase of the generator output. Each phase can be viewed one at a time by pushing phase select key (4). The upper display (1) is also used to show the various fault codes for system faults. For more information on fault codes, refer to the Service Manual Module SENR5809 for Fault Descriptions.* The lower display (2) shows: system battery voltage, engine hours, engine speed, engine oil pressure, and engine coolant temperature. The value for one of those conditions is displayed for two seconds, then the display scrolls to the value for the next condition. A small pointer identifies the engine condition that corresponds to the value that is showing. When engine meter key (3) is pressed, the lower display stops scrolling and continuously shows one particular value. The pointer flashes above the condition whose value is showing. When the engine meter key is pressed a second time, the display returns to scrolling.* The lower display also shows a relay status indicator. When a GSC relay is activated, the corresponding relay indicator (K1, K2, etc.) is shown on lower display (2). When a relay is not activated, the corresponding indicator (K1, K2, etc.) is not shown. Refer to the Service Manual Module SENR5809 for a description of the relay functions.Both the upper and lower display are used for programming functions when in the service mode. For more information, refer to the Service Manual Module SENR5809 for Service Modes.Keypad

The keypad (3) is used to control the information that is shown on upper display (1) and the lower display (2). The seven keys of keypad have two sets of functions: normal functions and service functions. For a description of the service functions of the keys, refer to the Service Manual Module SENR5809 for Service Models. The normal functions of the keys are as follows. Leftmost key (5) - This key only functions when the GSC is in the service mode. This key is used to scroll right. PHASE SELECT key (6) - This key selects which phase of the generator output shows on the GSC upper display. Pressing this key allows the operator to check the voltage, current, and frequency of each phase, one at a time. ENGINE METER key (7) - This key stops the scrolling of engine conditions on the lower display (2). The lower display continuously shows the value for one particular engine condition. The pointer for the particular engine condition flashes to indicate scrolling is stopped. Pressing the key again resumes the scrolling. LAMP TEST key (8) - This key perfumes a lamp test on the GSC and the optional alarm module for a maximum of ten seconds, if held pressed. On the GSC: the eight fault indicators are ON CONTINUOUSLY - every segment of the upper display (1) and the lower display (2) are ON. For the

Have questions with 104302-6600?

Group cross 104302-6600 ZEXEL

Toyo-Sha

104302-6600

9 400 616 421

5601510102

INJECTION-PUMP ASSEMBLY

2S107

2S107