Information injection-pump assembly

ZEXEL

104302-6550

1043026550

TOYO-SHA

4411510100

4411510100

Rating:

Cross reference number

ZEXEL

104302-6550

1043026550

TOYO-SHA

4411510100

4411510100

Zexel num

Bosch num

Firm num

Name

104302-6550

4411510100 TOYO-SHA

INJECTION-PUMP ASSEMBLY

2S135 * K

2S135 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

1.95

1.9

2

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

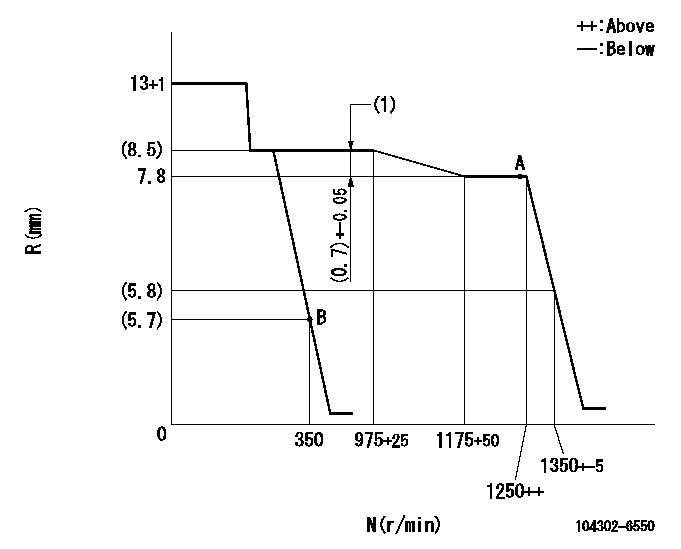

Injection quantity adjustment

Adjusting point

A

Rack position

7.8

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

46.9

45.9

47.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.7+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque control stroke

----------

----------

----------

----------

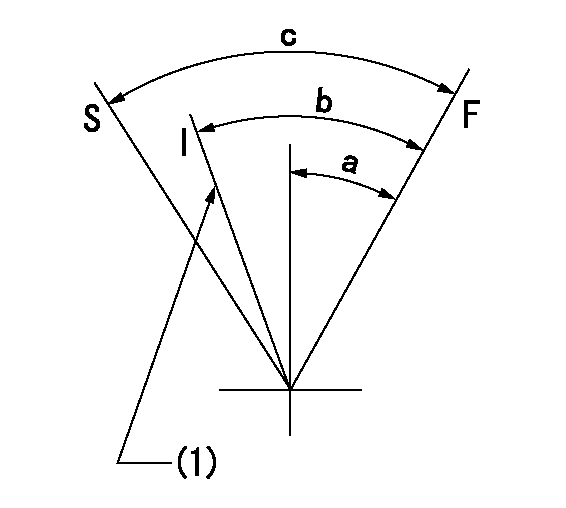

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set idling using the idle set spring.

----------

----------

a=12deg+-3deg b=18deg+-6deg c=29deg+-6deg

----------

----------

a=12deg+-3deg b=18deg+-6deg c=29deg+-6deg

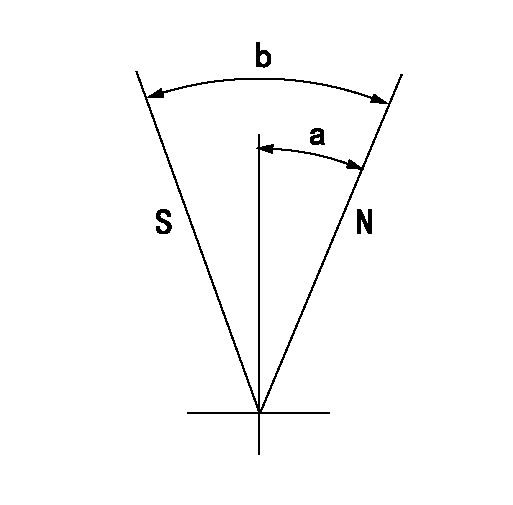

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=18deg+-3deg b=(38deg)

----------

----------

a=18deg+-3deg b=(38deg)

Information:

Torque for Standard Bolts, Nuts and Taperlock Studs

The following charts give general torques for bolts, nuts, and taperlock studs. For torque specifications not included in this section, refer to Torque Specifications, SENR3130, available from your Caterpillar dealer.

Torques for Bolts and Nuts With Standard Threads

Torques for Taperlock Studs

Use these standard torque values for all fasteners, unless otherwise specified in this manual or in the Service Manual.Torque for Metric Fasteners

Be very careful never to mix metric with customary (SAE standard) fasteners. Mismatched or incorrect fasteners will cause engine damage or malfunction and may even result in personal injury.Original fasteners removed from the engine should be saved for reassembly whenever possible. If new fasteners are needed, they must be of the same size and grade as the ones that are being replaced.

Material strength identification is usually shown on the bolt head by numbers (8.8, 10.9, etc.). The following chart gives general torque values for bolts and nuts. Use these standard torque values unless otherwise specified in this publication. Metric hardware must be replaced with metric hardware. Check Parts Manual for proper replacement.Torques for Bolts and Nuts with Metric Threads

Torque for Standard Hose Clamps-Worm Drive Band Type

The following chart gives the torques for initial installation of hose clamps on new hose and for reassembly or tightening of hose clamps on existing hose. Torque for Constant Torque Hose Clamps

Due to extreme temperature changes, hose will heat set. Heat settings causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new constant torque hose clamp will help prevent these failures. A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp.

Installation

Each installation application can be different depending on the type of hose, fitting material, and anticipated expansion or contraction of the hose and fittings. A torque wrench should be used for proper installation of constant torque hose clamps. Constant torque hose clamps should be installed as follows:* To allow for maximum expansion, install clamps at 5.7 N m (50 lb in).* To allow for equal expansion and contraction, install clamps at 10.2 N m (90 lb in).* To allow for maximum contraction, install clamps at 14.1 N m (125 lb in).

The following charts give general torques for bolts, nuts, and taperlock studs. For torque specifications not included in this section, refer to Torque Specifications, SENR3130, available from your Caterpillar dealer.

Torques for Bolts and Nuts With Standard Threads

Torques for Taperlock Studs

Use these standard torque values for all fasteners, unless otherwise specified in this manual or in the Service Manual.Torque for Metric Fasteners

Be very careful never to mix metric with customary (SAE standard) fasteners. Mismatched or incorrect fasteners will cause engine damage or malfunction and may even result in personal injury.Original fasteners removed from the engine should be saved for reassembly whenever possible. If new fasteners are needed, they must be of the same size and grade as the ones that are being replaced.

Material strength identification is usually shown on the bolt head by numbers (8.8, 10.9, etc.). The following chart gives general torque values for bolts and nuts. Use these standard torque values unless otherwise specified in this publication. Metric hardware must be replaced with metric hardware. Check Parts Manual for proper replacement.Torques for Bolts and Nuts with Metric Threads

Torque for Standard Hose Clamps-Worm Drive Band Type

The following chart gives the torques for initial installation of hose clamps on new hose and for reassembly or tightening of hose clamps on existing hose. Torque for Constant Torque Hose Clamps

Due to extreme temperature changes, hose will heat set. Heat settings causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new constant torque hose clamp will help prevent these failures. A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp.

Installation

Each installation application can be different depending on the type of hose, fitting material, and anticipated expansion or contraction of the hose and fittings. A torque wrench should be used for proper installation of constant torque hose clamps. Constant torque hose clamps should be installed as follows:* To allow for maximum expansion, install clamps at 5.7 N m (50 lb in).* To allow for equal expansion and contraction, install clamps at 10.2 N m (90 lb in).* To allow for maximum contraction, install clamps at 14.1 N m (125 lb in).

Have questions with 104302-6550?

Group cross 104302-6550 ZEXEL

Isuzu

Toyo-Sha

Isuzu

Toyo-Sha

104302-6550

4411510100

INJECTION-PUMP ASSEMBLY

2S135

2S135