Information injection-pump assembly

BOSCH

9 400 616 416

9400616416

ZEXEL

104302-6440

1043026440

TOYO-SHA

2801250103

2801250103

Rating:

Service parts 104302-6440 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

2251-1210-01

12.

Open Pre:MPa(Kqf/cm2)

12.7{130}

15.

NOZZLE SET

Include in #1:

104302-6440

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 416

9400616416

ZEXEL

104302-6440

1043026440

TOYO-SHA

2801250103

2801250103

Zexel num

Bosch num

Firm num

Name

104302-6440

9 400 616 416

2801250103 TOYO-SHA

INJECTION-PUMP ASSEMBLY

S148 * K 14BT INJECTION PUMP ASSY PES2K PE

S148 * K 14BT INJECTION PUMP ASSY PES2K PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

1.95

1.9

2

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

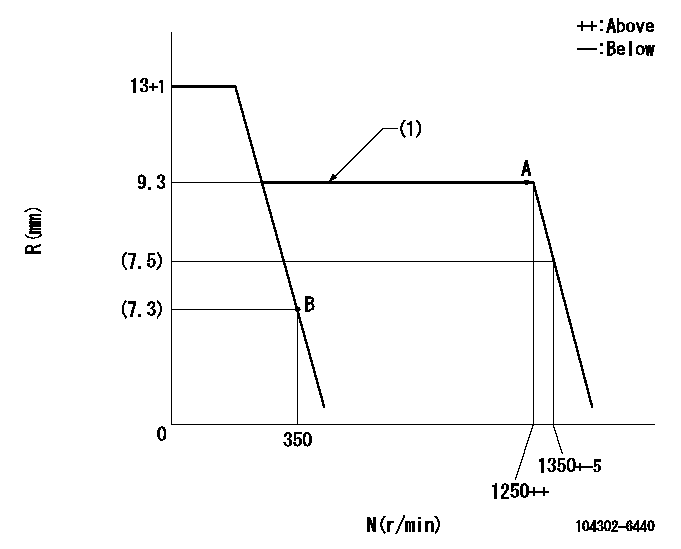

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

50.5

49.5

51.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.3+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Deliver without the torque control spring operating.

----------

----------

----------

----------

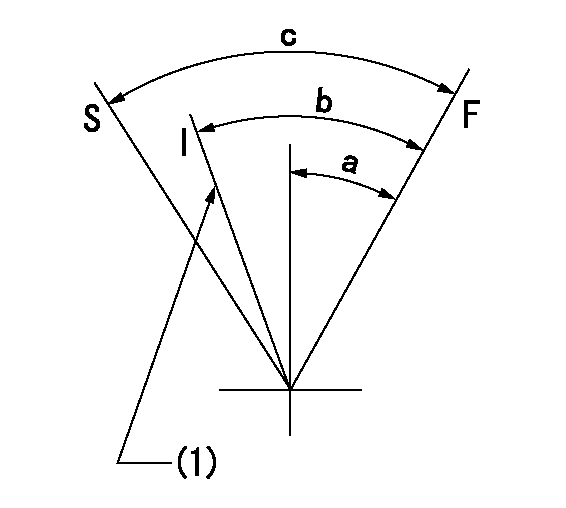

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set idling using the idle set spring.

----------

----------

a=16deg+-3deg b=22deg+-6deg c=(33deg)

----------

----------

a=16deg+-3deg b=22deg+-6deg c=(33deg)

Information:

Insert the special tool, Piston Ring Inserter to the turbine wheel and install the piston ring.(4) Installation of turbine wheel assembly Install using care not to damage the piston ring. After installation, turn the turbine wheel manually to check that it turns smoothly. If not, disassemble and reassemble again.(5) Installation of compressor wheel (a) Holding the center housing and turbine wheel shaft with fingers, insert slowly into the special tool, Holding Fixture. 1. When inserting, use care not to damage the turbine wheel assembly blades.2. Do not release the shaft before insertion as otherwise the turbine wheel assembly will drop. (b) After tightening the lock nut to specified torque, tighten additionally 110° using special tool, T-handle. Use care not to bend the shaft of turbine wheel assembly.(6) Installation of turbine housing Apply MOLYKOTE to the turbine housing attaching bolt threads and tighten temporarily. Then align match marks and tighten to specified torque. Use care not to damage the turbine wheel assembly blades.(7) Inspection of shaft play [Refer to Item (1) and (2), Section 5.3.1.](8) Installation of compressor housing (a) Lay the compressor housing on the back plate and face the compressor housing downward.(b) Align match marks put at time of disassembly and tighten to specified torque.(9) After assembly, turn the turbine wheel and compressor wheel manually to check that they turn smoothly. If they turn heavily or irregularly, disassemble and check causes.5.4 TD07 Turbocharger

Disassembly

Disassembly Procedure(1) Removal of turbine housing If the turbine housing is hard to remove, tap the turbine housing on its periphery using a plastic hammer or similar tool. The turbine wheel blades are easy to bend. Use care not to damage them.(2) Removal of compressor cover Using a plastic hammer or the similar tool, tap the compressor cover on its periphery and remove. Be careful not to hit the compressor wheel against compressor cover as its blades are easy to bend.(3) Removal of compressor wheel (a) Fit the bearing housing into the turbine housing which is clamped in a vise. (b) Hold the boss on the turbine wheel and remove the lock nut that attaches the compressor wheel. (c) Slowly lift up the compressor wheel to remove it.(4) Removal of insert (a) Remove the snap ring holding the insert into the bearing housing. Retain the snap ring by hand to prevent it from springing out when slipping off the snap ring pliers. (b) Hook the tips of the screwdrivers to the insert at the positions shown in the illustration, then carefully pry up the insert and thrust sleeve as a unit to remove them.Inspection and cleaning

Inspection Procedure(1) Cleaning (a) Immerse disassembled parts in a nonflammable solvent (Daido Kagaku Kogyo's Dai Cleaner T-30 or equivalent) to clean oily contamination. When a commercially-available neutral detergent is used for cleaning, make sure that it does not contain corrosive component. (b) Blow compressed air against the entire internal and external surfaces. (c) Using a plastic scraper or bristle brush, remove deposits from the surfaces. Then, dip parts in the

Disassembly

Disassembly Procedure(1) Removal of turbine housing If the turbine housing is hard to remove, tap the turbine housing on its periphery using a plastic hammer or similar tool. The turbine wheel blades are easy to bend. Use care not to damage them.(2) Removal of compressor cover Using a plastic hammer or the similar tool, tap the compressor cover on its periphery and remove. Be careful not to hit the compressor wheel against compressor cover as its blades are easy to bend.(3) Removal of compressor wheel (a) Fit the bearing housing into the turbine housing which is clamped in a vise. (b) Hold the boss on the turbine wheel and remove the lock nut that attaches the compressor wheel. (c) Slowly lift up the compressor wheel to remove it.(4) Removal of insert (a) Remove the snap ring holding the insert into the bearing housing. Retain the snap ring by hand to prevent it from springing out when slipping off the snap ring pliers. (b) Hook the tips of the screwdrivers to the insert at the positions shown in the illustration, then carefully pry up the insert and thrust sleeve as a unit to remove them.Inspection and cleaning

Inspection Procedure(1) Cleaning (a) Immerse disassembled parts in a nonflammable solvent (Daido Kagaku Kogyo's Dai Cleaner T-30 or equivalent) to clean oily contamination. When a commercially-available neutral detergent is used for cleaning, make sure that it does not contain corrosive component. (b) Blow compressed air against the entire internal and external surfaces. (c) Using a plastic scraper or bristle brush, remove deposits from the surfaces. Then, dip parts in the

Have questions with 104302-6440?

Group cross 104302-6440 ZEXEL

Ishikawajima-S

Isuzu

Toyo-Sha

104302-6440

9 400 616 416

2801250103

INJECTION-PUMP ASSEMBLY

S148

S148