Information injection-pump assembly

BOSCH

9 400 610 086

9400610086

ZEXEL

104302-6420

1043026420

TOYO-SHA

22512501020

22512501020

Rating:

Service parts 104302-6420 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5701-1210-00

12.

Open Pre:MPa(Kqf/cm2)

12.7{130}

15.

NOZZLE SET

Include in #1:

104302-6420

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 086

9400610086

ZEXEL

104302-6420

1043026420

TOYO-SHA

22512501020

22512501020

Zexel num

Bosch num

Firm num

Name

104302-6420

9 400 610 086

22512501020 TOYO-SHA

INJECTION-PUMP ASSEMBLY

S126 K 14BT INJECTION PUMP ASSY PES2K PE

S126 K 14BT INJECTION PUMP ASSY PES2K PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

1.95

1.9

2

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

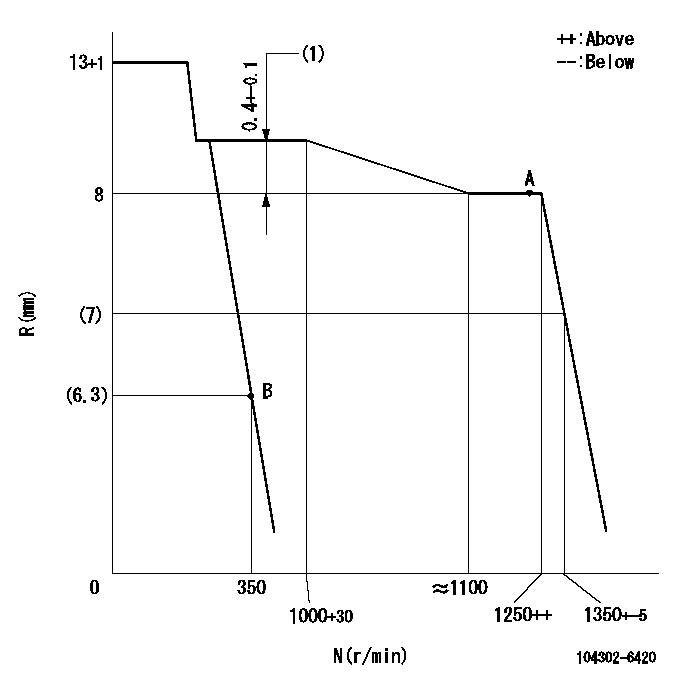

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

41

40

42

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack difference between N = N1 and N = N2

----------

N1=1250r/min N2=1000r/min

----------

----------

N1=1250r/min N2=1000r/min

----------

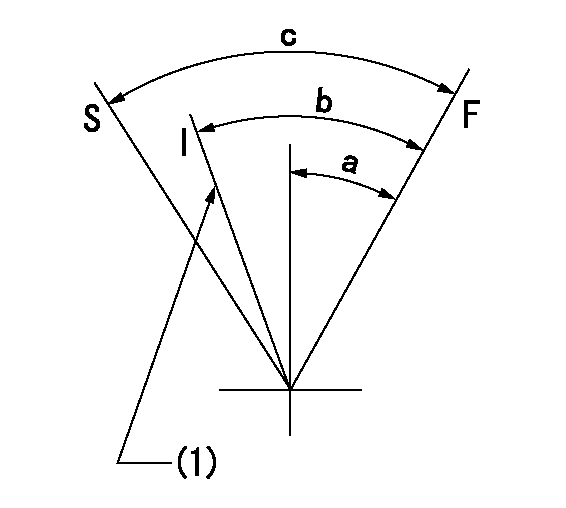

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set idling using the idle set spring.

----------

----------

a=16deg+-3deg b=22deg+-6deg c=33deg+-6deg

----------

----------

a=16deg+-3deg b=22deg+-6deg c=33deg+-6deg

Information:

(3) Check the unit seals installed in the impeller and water pump case for damage and wear. If defects are evident, or when water leaks during operation, replace the unit seals with new ones. Whenever the unit seal is removed, it must be replaced with a new one. (4) Using a gear puller or press, remove the ball bearings. Do not remove the ball bearing except for replacement. (5) When the impeller and flange are removed from the water pump shaft, it may result in insufficient interference. If the interference is below the specification even reassembly is two times or less they must be replaced with new ones.Reassembly

5.3 Thermostat

Removal and installation

Do not remove the thermostat case and front hanger unless they cause water leak or other defects.Inspection

Agitate water in the container with the stirrer to obtain uniform temperature. For the inspection, use the following procedures. (1) Slowly heat water to the thermostat valve opening temperature. Keep this condition for about five minutes and make sure that the valve is open.(2) Raise the water temperature up to 90°C. Keep the condition for five minutes and measure the lift of pellet.(3) Lower temperature down to 65°C or below and ensure that the valve is fully closed. If the thermostat is found defective in any of the above items, replace it with a new one. Support the thermostat so that the heat source will not directly heat the thermostat.5.4 Radiator

Inspection (1) Using a copper wire or similar device, remove dirt, mud, and bugs from the front of radiator core with care to prevent damage to tubings. (2) Connect a hose to one of the radiator ports, cap the other port, and immerse the radiator into water. Using a radiator cap tester, force the compressed air under the specified inspection pressure from the hose end to check for leaks.If there is a leak, resolder the point of leakage or replace the radiator.(3) Inspection of Radiator Cap Check the spring tension and sealing condition of the pressure valve and vent valve. If defective, replace. Check the pressure valve opening pressure, using a radiator cap tester.5.5 Inspection and Adjustment of V-belt Tension

Adjust the belt tension to obtain the specified belt deflection when the center of each belt is pressed with a force of approximately 98 N (10 kgf). 1. A slack belt can be a cause of overheating and undercharge.2. An excessively tight belt may result in damaged bearings and belts.3. When paired belts are to be replaced, be sure to replace both.5.6 Cleaning of Cooling System

If the radiator is used for a long time, rust, scale, mud, etc. are deposited inside, resulting in overheat. Clean the cooling system with city water by using the following procedures.The city water to be used should have the following properties.Required properties of city water 1. Use a cleaning solution if the radiator is seriously obstructed or coolant is seriously contaminated.2. When the cooling system is cleaned or washed with water, make sure that the coolant temperature is

5.3 Thermostat

Removal and installation

Do not remove the thermostat case and front hanger unless they cause water leak or other defects.Inspection

Agitate water in the container with the stirrer to obtain uniform temperature. For the inspection, use the following procedures. (1) Slowly heat water to the thermostat valve opening temperature. Keep this condition for about five minutes and make sure that the valve is open.(2) Raise the water temperature up to 90°C. Keep the condition for five minutes and measure the lift of pellet.(3) Lower temperature down to 65°C or below and ensure that the valve is fully closed. If the thermostat is found defective in any of the above items, replace it with a new one. Support the thermostat so that the heat source will not directly heat the thermostat.5.4 Radiator

Inspection (1) Using a copper wire or similar device, remove dirt, mud, and bugs from the front of radiator core with care to prevent damage to tubings. (2) Connect a hose to one of the radiator ports, cap the other port, and immerse the radiator into water. Using a radiator cap tester, force the compressed air under the specified inspection pressure from the hose end to check for leaks.If there is a leak, resolder the point of leakage or replace the radiator.(3) Inspection of Radiator Cap Check the spring tension and sealing condition of the pressure valve and vent valve. If defective, replace. Check the pressure valve opening pressure, using a radiator cap tester.5.5 Inspection and Adjustment of V-belt Tension

Adjust the belt tension to obtain the specified belt deflection when the center of each belt is pressed with a force of approximately 98 N (10 kgf). 1. A slack belt can be a cause of overheating and undercharge.2. An excessively tight belt may result in damaged bearings and belts.3. When paired belts are to be replaced, be sure to replace both.5.6 Cleaning of Cooling System

If the radiator is used for a long time, rust, scale, mud, etc. are deposited inside, resulting in overheat. Clean the cooling system with city water by using the following procedures.The city water to be used should have the following properties.Required properties of city water 1. Use a cleaning solution if the radiator is seriously obstructed or coolant is seriously contaminated.2. When the cooling system is cleaned or washed with water, make sure that the coolant temperature is

Have questions with 104302-6420?

Group cross 104302-6420 ZEXEL

Ishikawajima-S

Isuzu

Toyo-Sha

104302-6420

9 400 610 086

22512501020

INJECTION-PUMP ASSEMBLY

S126

S126