Information injection-pump assembly

BOSCH

9 400 616 414

9400616414

ZEXEL

104302-6220

1043026220

TOYO-SHA

2501250102

2501250102

Rating:

Service parts 104302-6220 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5701-1210-00

12.

Open Pre:MPa(Kqf/cm2)

12.7{130}

15.

NOZZLE SET

Include in #1:

104302-6220

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 414

9400616414

ZEXEL

104302-6220

1043026220

TOYO-SHA

2501250102

2501250102

Zexel num

Bosch num

Firm num

Name

104302-6220

9 400 616 414

2501250102 TOYO-SHA

INJECTION-PUMP ASSEMBLY

S111 K

S111 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

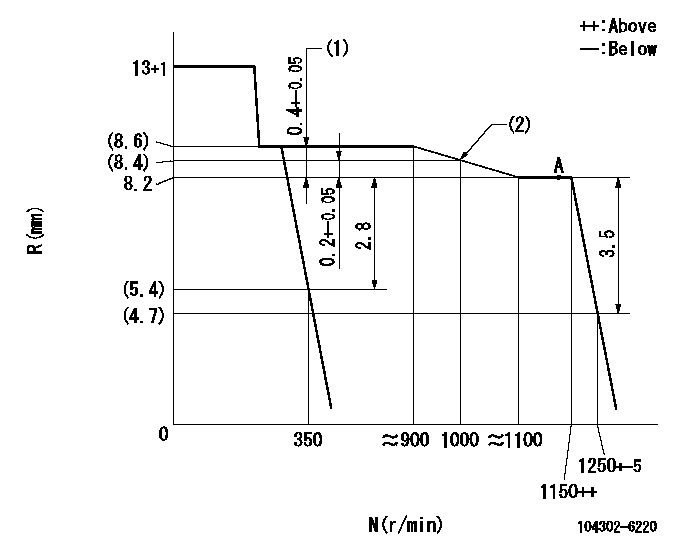

Injection quantity adjustment

Adjusting point

A

Rack position

8.2

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

37.5

36.5

38.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.4+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque control stroke

(2)Apply the torque control spring so that the fuel injection quantity passes through this point.

----------

----------

----------

----------

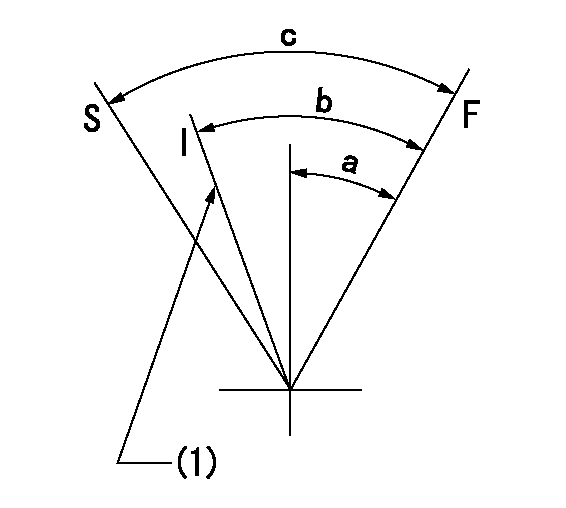

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set idling using the idle set spring.

----------

----------

a=27deg+-3deg b=30deg+-6deg c=(40deg)

----------

----------

a=27deg+-3deg b=30deg+-6deg c=(40deg)

Information:

Governor Linkage Adjustment

(1) Rod. (2) Nut. (3) Control lever. (4) Lever. (5) Pin. (6) High idle stop. (7) Locknut. (8) Low idle stop. (9) Locknut. (10) Decelerator treadle. (11) Floor plate. (12) Accelerator treadle. (13) Lever. (14) Rod. (15) Locknut. (16) Lever. (17) Locknut. (A) 9.7 1.5 mm (.38 .06 in). (B) 4.8 1.5 mm (.19 .06 in). (C) 38.1 1.5 mm (1.50 .06 in). (D) 60.5 3.0 mm (2.38 .12 in).Governor Linkage Adjustment

DO NOT USE control lever (3), or decelerator treadle (10) to shut OFF the engine.To shut engine OFF, pull up on accelerator treadle (12).1. Tighten nut (2) just enough so position of control lever (3) is not affected by the operation of the accelerator treadle (12) and decelerator treadle (10).2. With the parking brake ON and engine stopped, BE SURE disconnect switch is OFF.3. Remove pin (5).4. Loosen LOW IDLE stop (8) and HIGH IDLE stop (6) so they do not touch lever (13).5. Move control lever (3) to LOW IDLE position.6. Turn LOW IDLE stop (8) until it touches lever (13) and tighten locknut (9).7. Adjust length of rod (14) so distance from top of lever (16) to bottom of floor plate (11) is (C) 38.1 1.5 mm (1.50 .06 in) as shown.8. Loosen locknut (15) and adjust length of rod so top of decelerator treadle (10) is (B) 4.8 mm (.19 in) above floor plate (11) as shown. If machine is equipped with a thick floor insulation pad, (used with enclosed cab), adjust decelerator treadle (10) so top of treadle is (A) 9.7 1.5 mm (.38 .06 in) above top of floor plate and tighten locknut (15).9. Move control lever (3) to HIGH IDLE position.10. Turn HIGH IDLE stop (6) until it touches lever (13) and tighten locknut (7).11. Loosen locknut (17) and adjust accelerator treadle (12) so that distance from bottom of plate on treadle to top of floor plate (11) is (D) 60.5 3.0 mm (2.38 .12 in) as shown.12. Move lever (4) to HIGH IDLE position and adjust length of rod (1) so pin (5) can be installed.13. Install pin (5).

DO NOT adjust the linkage so the treadle can be used to shut off the engine. If the operator is in a standing position and places a foot on the treadle, the engine could be unexpectedly shut off, creating a situation where the machine can be difficult to control.

814B, 815B, 816B, 966D

1. Set governor shaft to the off position (approximately 35° right of twelve o'clock) and attach lever (1).2. Adjust cable assembly (2) to within 3 mm (.12 in) of the end of travel and tighten bulkhead (3) nuts to ... 100 15

Have questions with 104302-6220?

Group cross 104302-6220 ZEXEL

Isuzu

Toyo-Sha

104302-6220

9 400 616 414

2501250102

INJECTION-PUMP ASSEMBLY

S111

S111