Information injection-pump assembly

ZEXEL

104302-3930

1043023930

ISUZU

5156005180

5156005180

Rating:

Service parts 104302-3930 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-039-1

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104302-3930

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104302-3930

1043023930

ISUZU

5156005180

5156005180

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105000-1650

Bosch type code

DN0SD2110

Nozzle holder

105081-3140

Opening pressure

MPa

11.8

Opening pressure

kgf/cm2

120

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.1

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

38.5

37.5

39.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.1+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

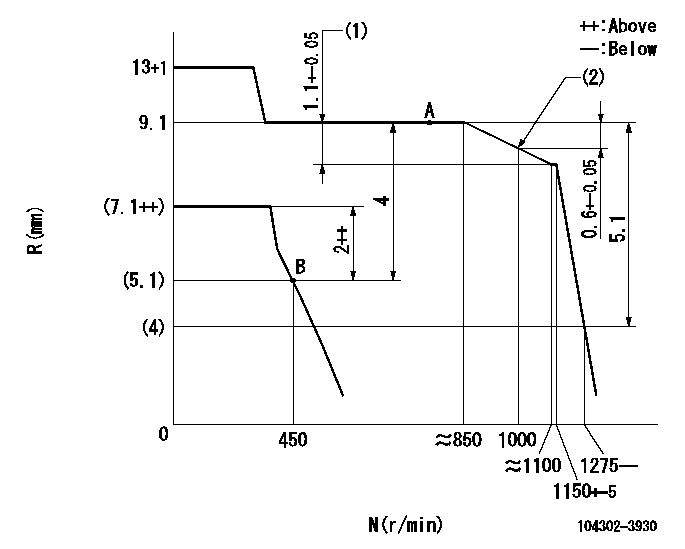

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque control stroke

(2)Apply the torque control spring so that the fuel injection quantity passes through this point.

----------

----------

----------

----------

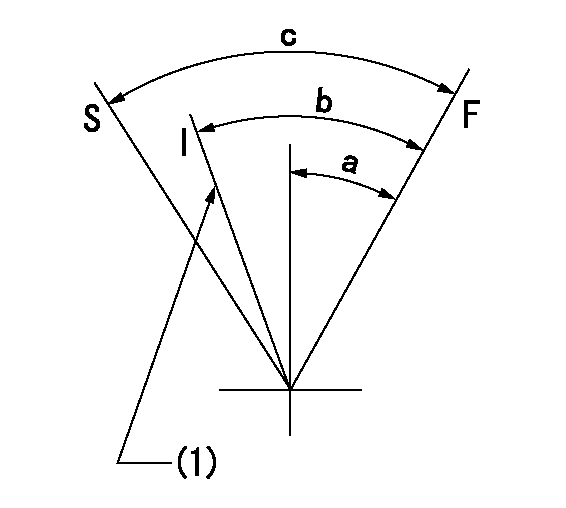

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set at point B-aa using the idle set spring.

----------

aa=0.5mm

----------

a=20deg+-2deg b=25.5deg+-6deg c=38deg+-6deg

----------

aa=0.5mm

----------

a=20deg+-2deg b=25.5deg+-6deg c=38deg+-6deg

Information:

Final Fuel Filter

The filter element collects and holds contaminants and cannot be washed or otherwise restored.To remove the used filter, proceed as follows:1. Stop the engine and close the diesel fuel line valve (if equipped).2. Unscrew and remove filter. 3. Clean the gasket sealing surfaces on the filter bases. 4. Lubricate the new filter gasket with clean diesel fuel.

Do not pour fuel into the new filter element before installing. Prime the system as instructed in the topic, PRIMING THE FUEL SYSTEM.

5. Tighten the filter by hand until the gasket contacts the base, then tighten 1/2 to 3/4 turn more.6. Start the engine and run at 1000 rpm for several minutes and check for leaks. If the engine fails to start, prime the fuel system. See the topic TO PRIME THE SYSTEM. Keep New Fuel Filters On Hand

Extra filters should be kept on hand for replacement. Always keep filters wrapped in their original carton to insure against dust and dirt accumulation which will shorten the life of the filters or may cause damage to the fuel injection equipment.To Prime The System

If air is trapped in the fuel system, the diesel engine will either not start, or will misfire. Then it is necessary to prime the system.The fuel priming pump is mounted on the fuel filter base. If the fuel filter is changed or if the engine has run out of fuel, prime the fuel system as follows: 1. Be sure the fuel line valve is open and the engine shutoff control is off.2. Unlock the fuel priming pump.3. Operate priming pump until increased resistance is felt.4. Lock fuel priming pump.If the engine fails to start or continues to misfire or smoke, further bleeding is necessary. With engine running, or with the use of the priming pump, loosen fuel line nuts, one at a time, several times in succession and allow fuel to run until free of air bubbles. Tighten fuel line nuts.

LOOSENING FUEL INJECTION LINE TO BLEED SYSTEMFuel Injection Equipment

When improper fuel injection is affecting engine operation, a systematic check should be made to determine the cause. The most likely cause is dirt or water in the fuel. Drain the sediment from the fuel tank. Check the fuel pressure gauge as mentioned in the topic, FUEL FILTERING SYSTEM. Replace the filters if necessary. Then prime the fuel system until clean fuel reaches the fuel injection pumps. If the fuel system is air bound, priming the system will overcome the difficulty.If the engine is running irregularly, smoking, or knocking, a fuel injection valve may not be spraying the fuel properly.Direct Injection System

The fuel system of direct injection engines is essentially the same as precombustion chamber engines. The absence of the precombustion chamber requires a different fuel nozzle and adapter. Externally the direct injection fuel nozzle resembles the precombustion chamber nozzle except it is longer in length. Nozzle testing and replacement procedure is the same as illustrated for the precombustion chamber engines, except that an extracting tool is used to remove

The filter element collects and holds contaminants and cannot be washed or otherwise restored.To remove the used filter, proceed as follows:1. Stop the engine and close the diesel fuel line valve (if equipped).2. Unscrew and remove filter. 3. Clean the gasket sealing surfaces on the filter bases. 4. Lubricate the new filter gasket with clean diesel fuel.

Do not pour fuel into the new filter element before installing. Prime the system as instructed in the topic, PRIMING THE FUEL SYSTEM.

5. Tighten the filter by hand until the gasket contacts the base, then tighten 1/2 to 3/4 turn more.6. Start the engine and run at 1000 rpm for several minutes and check for leaks. If the engine fails to start, prime the fuel system. See the topic TO PRIME THE SYSTEM. Keep New Fuel Filters On Hand

Extra filters should be kept on hand for replacement. Always keep filters wrapped in their original carton to insure against dust and dirt accumulation which will shorten the life of the filters or may cause damage to the fuel injection equipment.To Prime The System

If air is trapped in the fuel system, the diesel engine will either not start, or will misfire. Then it is necessary to prime the system.The fuel priming pump is mounted on the fuel filter base. If the fuel filter is changed or if the engine has run out of fuel, prime the fuel system as follows: 1. Be sure the fuel line valve is open and the engine shutoff control is off.2. Unlock the fuel priming pump.3. Operate priming pump until increased resistance is felt.4. Lock fuel priming pump.If the engine fails to start or continues to misfire or smoke, further bleeding is necessary. With engine running, or with the use of the priming pump, loosen fuel line nuts, one at a time, several times in succession and allow fuel to run until free of air bubbles. Tighten fuel line nuts.

LOOSENING FUEL INJECTION LINE TO BLEED SYSTEMFuel Injection Equipment

When improper fuel injection is affecting engine operation, a systematic check should be made to determine the cause. The most likely cause is dirt or water in the fuel. Drain the sediment from the fuel tank. Check the fuel pressure gauge as mentioned in the topic, FUEL FILTERING SYSTEM. Replace the filters if necessary. Then prime the fuel system until clean fuel reaches the fuel injection pumps. If the fuel system is air bound, priming the system will overcome the difficulty.If the engine is running irregularly, smoking, or knocking, a fuel injection valve may not be spraying the fuel properly.Direct Injection System

The fuel system of direct injection engines is essentially the same as precombustion chamber engines. The absence of the precombustion chamber requires a different fuel nozzle and adapter. Externally the direct injection fuel nozzle resembles the precombustion chamber nozzle except it is longer in length. Nozzle testing and replacement procedure is the same as illustrated for the precombustion chamber engines, except that an extracting tool is used to remove