Information injection-pump assembly

ZEXEL

104302-3910

1043023910

ISUZU

5156005290

5156005290

Rating:

Service parts 104302-3910 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-039-1

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

104302-3910

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104302-3910

1043023910

ISUZU

5156005290

5156005290

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105000-1650

Bosch type code

DN0SD2110

Nozzle holder

105081-3140

Opening pressure

MPa

11.8

Opening pressure

kgf/cm2

120

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-2

Pre-stroke

mm

2.1

2.05

2.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

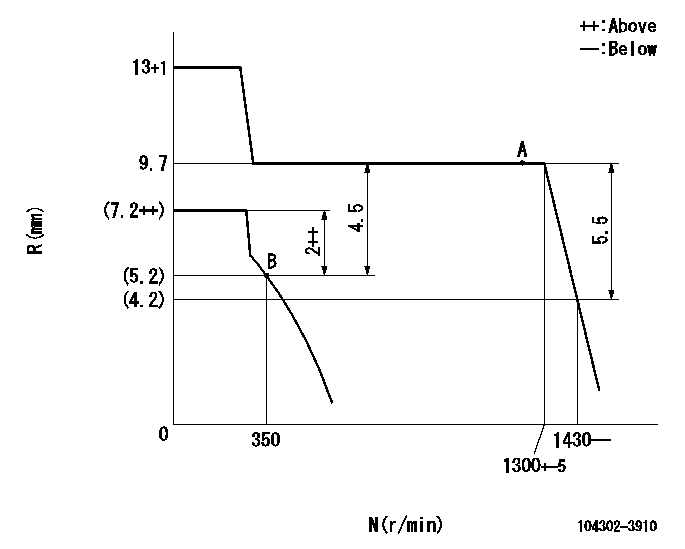

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

45.5

44.5

46.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.2+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

----------

----------

----------

----------

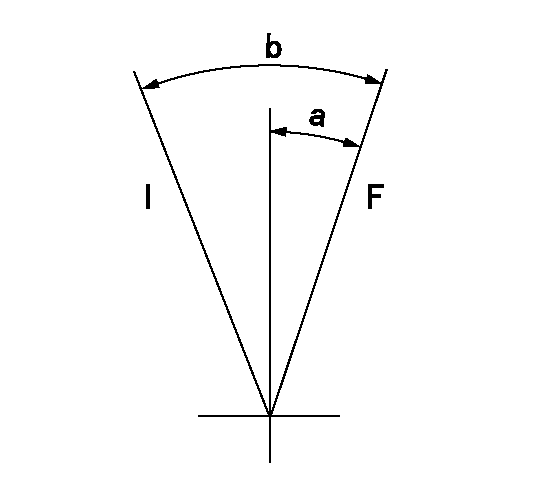

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=20deg+-2deg b=32.5deg+-6deg

----------

----------

a=20deg+-2deg b=32.5deg+-6deg

Information:

Be sure to read the correct side of the dipstick. The ADD and FULL levels are not the same when checking the oil while stopped or while idling.

Checking Oil Pressure

Immediately after starting, and frequently during operation, observe the oil pressure gauge reading. The indicator should register in the NORMAL range. If the indicator fluctuates or registers below NORMAL range:1. Move the governor control to low idle position.2. Check the oil level. Be sure to read the ENGINE IDLING side of the dipstick.3. Add oil until the oil level is at the FULL mark on the ENGINE IDLING side of the dipstick. Do not overfill.4. Check for oil leaks.5. If necessary, stop the engine and have repairs made.Draining Engine Oil

With engine stopped and oil warm:1. Remove the crankcase oil drain plug.2. Allow the oil to drain. 3. Clean and install the drain plug.OR, if a sump pump is used:1. Connect a suitable drain line and container to the pump outlet.2. With engine stopped and oil warm, open the sump pump valve to the engine crankcase drain line: The two marks on the valve must be turned so that one mark points to the pump, and the second mark points to the engine drain line.3. Operate the sump pump handle until the crankcase is empty.4. Close the valve to the engine crankcase drain line.Cleaning the Breather

1. Release the hose clamp and disconnect the fumes disposal tube.2. Remove the breather assembly. 3. Wash the breather in solvent.4. Allow to drain dry and then wipe.5. Inspect the gasket. Install a new gasket if necessary.6. Install the breather.7. Connect the fumes disposal tube. Changing Oil Filter

1. Unscrew and remove the filter. 2. Be sure the old filter gasket did not remain attached inside the filter base: Leaking will occur between the new filter gasket and this old gasket.3. Wipe the filter base. 4. Apply a thin coat of clean oil to the gasket of the new filter. 5. Install the new filter: Hand tighten the filter 3/4turn after the filter gasket contacts the base. Use rotation index numbers, which are painted on the filter can, as a guide for proper tightening. Filling the Crankcase

1. Fill the crankcase to the safe starting range on the ENGINE STOPPED side of the dipstick. See the Lubrication Specifications for refill capacity and proper oil viscosity. 2. Start the engine and check for oil leaks.3. After the engine is warm, check the oil level with the engine idling.4. Add oil if necessary to maintain the oil level at the FULL mark on the ENGINE IDLING side of the dipstick.Fan Drive Bearings

Lubricate the fan drive bearings with lubricating grease through one fitting, 1 or 2 strokes.

LOCATION OF 4B4550 PRESSURE RELIEF FITTING AND 2D4867 FITTING SHOWN IN THE STANDARD LOCATION.If the grease fitting is not readily accessible, it may be necessary to1. Remove the 4B4550 Fitting (relief) from the fan mounting bracket assembly and install the 2D4867 Fitting in its place.2. Install the 4B4550 Fitting (relief) in place of the