Information injection-pump assembly

ZEXEL

104302-3820

1043023820

Rating:

Service parts 104302-3820 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5701-1210-00

12.

Open Pre:MPa(Kqf/cm2)

12.7{130}

15.

NOZZLE SET

Include in #1:

104302-3820

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104302-3820

1043023820

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

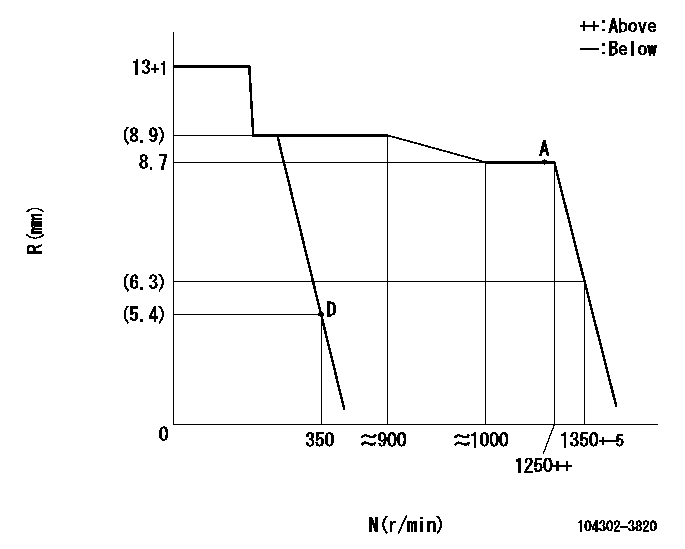

Injection quantity adjustment

Adjusting point

A

Rack position

8.7

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

43

42

44

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

5.4+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

----------

----------

----------

----------

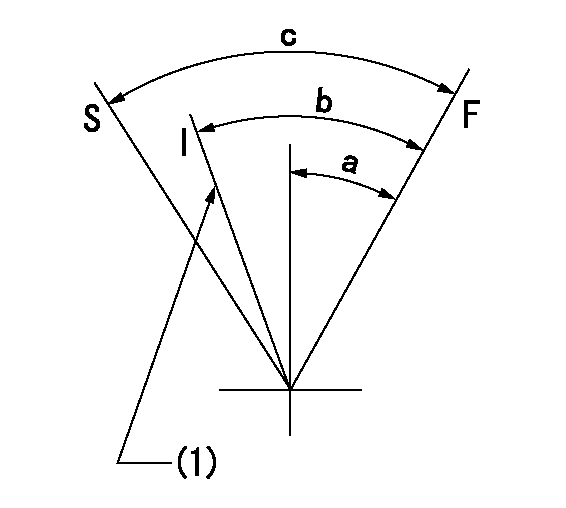

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set idling using the idle set spring.

----------

----------

a=27deg+-3deg b=33deg+-5deg c=(42deg)

----------

----------

a=27deg+-3deg b=33deg+-5deg c=(42deg)

Information:

Safety is everyone's business and is basically the use of good common sense. A general guide of safety precautions are given below, but each installation has its own peculiarities which cannot always be predicted and covered by established rules. Past experience and common sense are needed for the necessary safety measures. Attention to safety will help avoid serious accidents. Be alert. Watch for hazards. Use preventive measures. Correct deficiencies immediately.The following safety precautions are a general guide to safe operation:1. To prevent personal injury, install guards over all exposed rotating parts.2. To prevent hearing damage, wear ear protective devices if working inside an enclosed engine room with engine running.3. To prevent head injury, wear safety hat when working in the area of overhead equipment.4. Wear safety glasses and shoes as required. 5. Do not wear loose clothing whenever working around engines or machinery.6. Wipe up spilled oil, fuel or coolant.7. Keep batteries in a well ventilated area. Do not smoke around batteries. Hydrogen gas, which is present in the area of the batteries, is highly explosive.8. Provide adequate and safe waste oil disposal.9. Store oily rags in fireproof containers. Don't leave rags on engine.

When using pressure air, wear safety glasses and protective clothing. Maximum air pressure, used for cleaning, must be below 30 PSI (2 kg/cm2).

10. Remove all tools, electrical cords and other loose items from the engine before starting.11. Disconnect and tape the battery ground lead before working on an engine to prevent accidental starting. Be sure an automatic start-stop system cannot operate and start the engine while working on it.12. Do not attempt repairs you do not understand. Follow instructions.13. Stop engine before adjusting or repairing engine or driven equipment.14. Remove radiator cap slowly. Cooling systems can be pressurized and hot fluid will flash to steam as pressure is removed.15. Never start an engine with the governor linkage disconnected.16. Replace or repair broken or damaged equipment. Use proper tools.17. Do not smoke while refueling. Observe NO SMOKING signs.18. Never store flammable liquids near the engine.19. All electrical equipment must be grounded according to local building codes.20. Check all connections periodically for tightness and insulation.21. Insulate all connections and disconnected wires.22. Do not use carbon tetrachloride fire extinguishers. Fumes are toxic and the liquid has a deteriorating effect on insulation. 23. Do not touch the heat sink on the generator regulator when the generator is running. It is electrically "hot".24. Do not work on electrically "hot" equipment.25. Always disconnect the engine starter circuit when working on the generator.26. Hot engine oil can cause burns when drained. Allow the oil to cool below 140°F or provide protection when draining the hot oil.27. Never remove a plug to check pressure with the engine running. Shut down the engine and assure there is no pressure before removing plug.28. When starting an engine after repair, make provisions for shutting off air supply in case there is an overspeed on start up.29. Never look into an open cylinder port and turn over

When using pressure air, wear safety glasses and protective clothing. Maximum air pressure, used for cleaning, must be below 30 PSI (2 kg/cm2).

10. Remove all tools, electrical cords and other loose items from the engine before starting.11. Disconnect and tape the battery ground lead before working on an engine to prevent accidental starting. Be sure an automatic start-stop system cannot operate and start the engine while working on it.12. Do not attempt repairs you do not understand. Follow instructions.13. Stop engine before adjusting or repairing engine or driven equipment.14. Remove radiator cap slowly. Cooling systems can be pressurized and hot fluid will flash to steam as pressure is removed.15. Never start an engine with the governor linkage disconnected.16. Replace or repair broken or damaged equipment. Use proper tools.17. Do not smoke while refueling. Observe NO SMOKING signs.18. Never store flammable liquids near the engine.19. All electrical equipment must be grounded according to local building codes.20. Check all connections periodically for tightness and insulation.21. Insulate all connections and disconnected wires.22. Do not use carbon tetrachloride fire extinguishers. Fumes are toxic and the liquid has a deteriorating effect on insulation. 23. Do not touch the heat sink on the generator regulator when the generator is running. It is electrically "hot".24. Do not work on electrically "hot" equipment.25. Always disconnect the engine starter circuit when working on the generator.26. Hot engine oil can cause burns when drained. Allow the oil to cool below 140°F or provide protection when draining the hot oil.27. Never remove a plug to check pressure with the engine running. Shut down the engine and assure there is no pressure before removing plug.28. When starting an engine after repair, make provisions for shutting off air supply in case there is an overspeed on start up.29. Never look into an open cylinder port and turn over