Information injection-pump assembly

ZEXEL

103862-0320

1038620320

Rating:

Service parts 103862-0320 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-12-3403

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

ZEXEL

103862-0320

1038620320

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

131424-6620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-5-

6-2-7-8

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 45 44.5 45.5

Cal 1-3 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-4 deg. 77 76.5 77.5

Cal 1-4 deg. 77 76.5 77.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-6 deg. 167 166.5 167.5

Cal 1-6 deg. 167 166.5 167.5

Difference between angles 5

Cyl.1-2 deg. 212 211.5 212.5

Cyl.1-2 deg. 212 211.5 212.5

Difference between angles 6

Cal 1-7 deg. 269.5 269 270

Cal 1-7 deg. 269.5 269 270

Difference between angles 7

Cal 1-8 deg. 301.5 301 302

Cal 1-8 deg. 301.5 301 302

Injection quantity adjustment

Adjusting point

A

Rack position

14

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

413

406.4

419.6

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

60

55

65

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

14

Boost pressure

kPa

4

1.3

6.7

Boost pressure

mmHg

30

10

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

15.4

Boost pressure

kPa

20

16

24

Boost pressure

mmHg

150

120

180

Test data Ex:

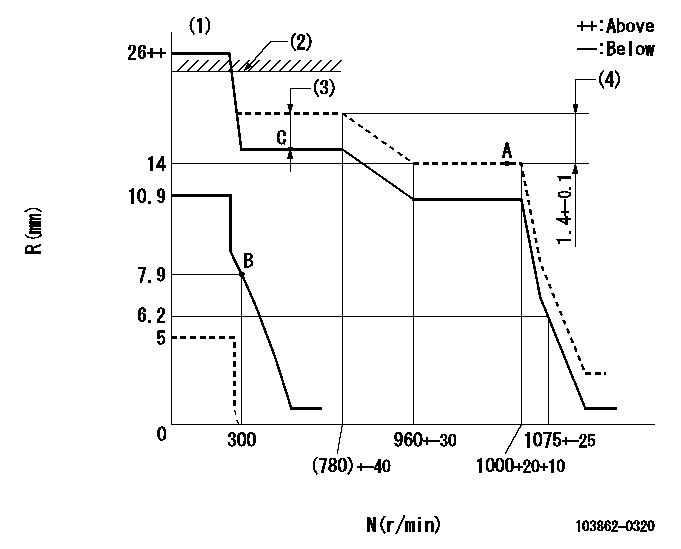

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Boost compensator stroke: BCL

(4)Rack difference between N = N1 and N = N2

----------

K=(15) RAL=15.9+0.2mm BCL=1.4+-0.1mm N1=1000r/min N2=700r/min

----------

----------

K=(15) RAL=15.9+0.2mm BCL=1.4+-0.1mm N1=1000r/min N2=700r/min

----------

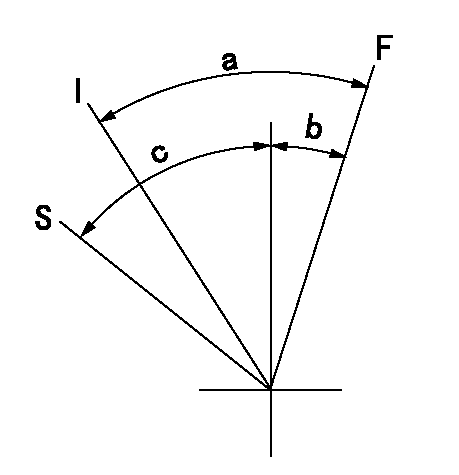

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(40deg)+-5deg b=(30deg)+-5deg c=30deg+-5deg

----------

----------

a=(40deg)+-5deg b=(30deg)+-5deg c=30deg+-5deg

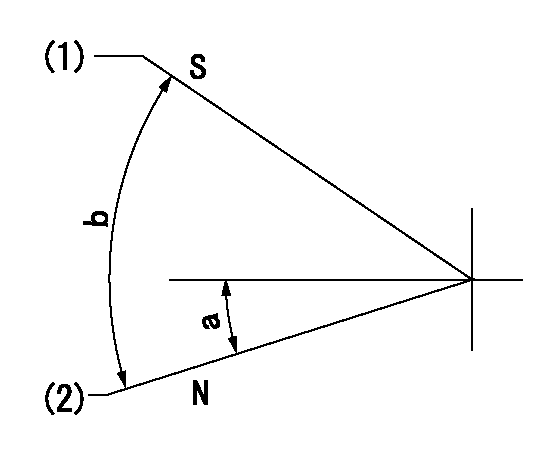

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at rack position = aa, speed = bb.

(2)Clearance between stopper bolt and lever must be cc.

----------

aa=5mm bb=100r/min cc=2+1mm

----------

a=16deg+-5deg b=40deg+-5deg

----------

aa=5mm bb=100r/min cc=2+1mm

----------

a=16deg+-5deg b=40deg+-5deg

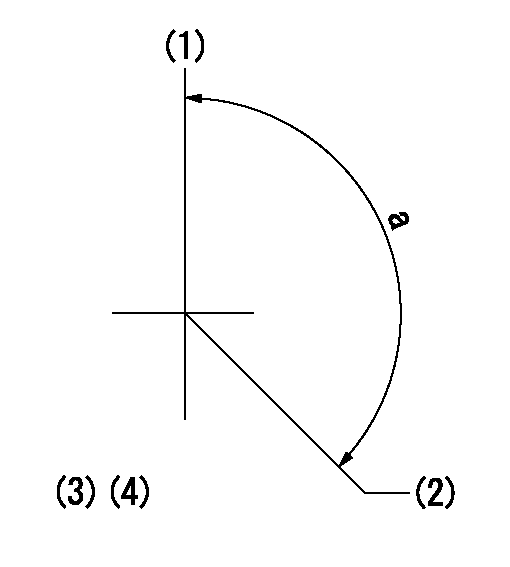

Timing setting

(1)Pump vertical direction

(2)Position of spline gear's aligning mark at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=36deg

----------

a=(130deg)

----------

aa=36deg

----------

a=(130deg)

Information:

PRIMARY FUEL FILTERFINAL FUEL FILTER ELEMENT: The filter element collects and holds contaminants and cannot be washed or otherwise restored. To remove the used filter element, proceed as follows:1. Stop the engine and close the diesel fuel line valve (if equipped).2. Unscrew and remove filter.3. Clean the gasket sealing surface on the filter base.

Do not pour fuel into the new filter elements before installing. Prime the system as instructed in the topic, PRIMING THE FUEL SYSTEM.

4. Lubricate the filter gasket with clean diesel fuel.5. Tighten the filter by hand, only tight enough to prevent leaks. (Do not overtighten.)6. Prime the fuel system. Refer to the topic "PRIMING THE FUEL SYSTEM"

REMOVING FUEL FILTER ELEMENT KEEP A NEW FUEL FILTER ON HAND: An extra filter should be kept on hand for replacement. Always keep the filter wrapped in its original carton to insure against dust and dirt accumulation which will shorten the life of the filter or may cause damage to the fuel injection equipment.PRIMING THE FUEL SYSTEM: Any time the fuel flow is broken and air is allowed to get into the fuel system, the system must be primed. If air is left in the lines, the fuel system may become air bound, resulting in inability to start the engine or the misfiring of one or more cylinders.

PRIMING THE FUEL SYSTEMThe fuel priming pump is mounted on the fuel filter housing as shown. If only the fuel filter is changed follow steps 1 through 5. If the fuel system is completely drained or if the engine has run out of fuel continue with steps through 10.1. Check to see that the fuel line valve is open.2. Open the fuel filter vent valve on the fuel filter housing.3. Loosen the knob of the fuel priming pump.4. Operate the pump plunger in and out until the flow of fuel from the vent valve is continuous and free of air bubbles.5. Close vent valve.6. Move governor control to the shut-off position and loosen fuel line nuts (one at a time) at the pump housing.7. Operate priming pump until clear fuel flows from the fuel pump lines. Tighten fuel line nut.8. Repeat for each fuel pump.9. Lock the knob of the fuel priming pump to its original position.10. Start the engine. If the engine does not run smoothly further bleeding may be necessary. With the engine running, open and close the fuel injection line nuts, one at a time, several times in succession to be sure all the air is bled from the system. Tighten fuel line nuts to 30 lbs.ft. (4,1 mkg). Do not overtighten.Fuel Injection Equipment

When improper fuel injection is affecting engine operation, a systematic check should be made to determine the cause. The most likely cause is dirt or water in the fuel. Drain the sediment from the fuel tank. Check the fuel pressure gauge as mentioned in the topic, FUEL FILTERING SYSTEM. Replace the filter element if necessary. Then prime the fuel system until clean fuel reaches the fuel