Information injection-pump assembly

BOSCH

9 400 616 379

9400616379

ZEXEL

103860-0031

1038600031

KOMATSU

6164711510

6164711510

Rating:

Service parts 103860-0031 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-12-3403

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 379

9400616379

ZEXEL

103860-0031

1038600031

KOMATSU

6164711510

6164711510

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

131425-1920

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-5-

6-2-7-8

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 45 44.5 45.5

Cal 1-3 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-4 deg. 77 76.5 77.5

Cal 1-4 deg. 77 76.5 77.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-6 deg. 167 166.5 167.5

Cal 1-6 deg. 167 166.5 167.5

Difference between angles 5

Cyl.1-2 deg. 212 211.5 212.5

Cyl.1-2 deg. 212 211.5 212.5

Difference between angles 6

Cal 1-7 deg. 269.5 269 270

Cal 1-7 deg. 269.5 269 270

Difference between angles 7

Cal 1-8 deg. 301.5 301 302

Cal 1-8 deg. 301.5 301 302

Injection quantity adjustment

Adjusting point

A

Rack position

15.2

Pump speed

r/min

1050

1050

1050

Each cylinder's injection qty

mm3/st.

470

462.5

477.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

61.3

61.3

Boost pressure

mmHg

460

460

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

60

55

65

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

13.3

Boost pressure

kPa

26

25.3

26.7

Boost pressure

mmHg

195

190

200

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

15.2

Boost pressure

kPa

48

41.3

54.7

Boost pressure

mmHg

360

310

410

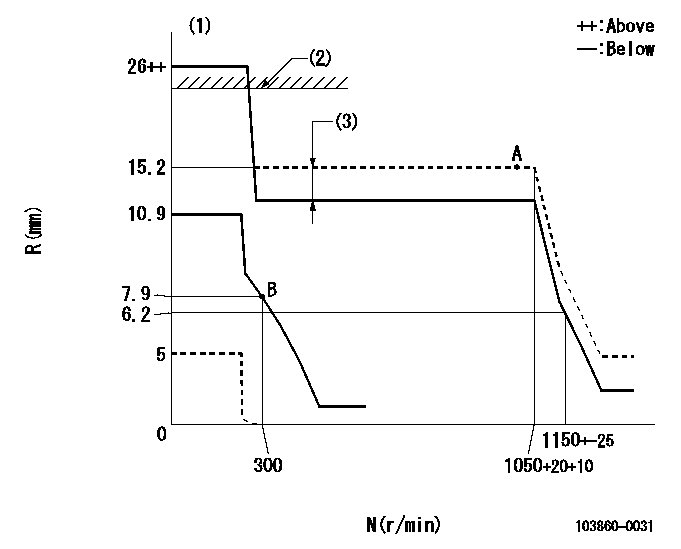

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Boost compensator stroke: BCL

----------

K=(15) RAL=15.7+0.2mm BCL=1.9+-0.1mm

----------

----------

K=(15) RAL=15.7+0.2mm BCL=1.9+-0.1mm

----------

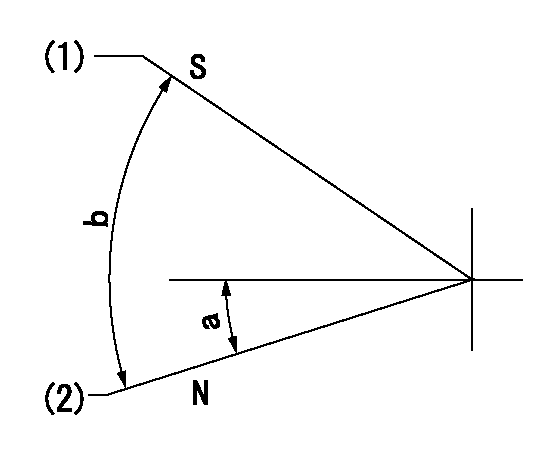

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(40deg)+-5deg b=(30deg)+-5deg

----------

----------

a=(40deg)+-5deg b=(30deg)+-5deg

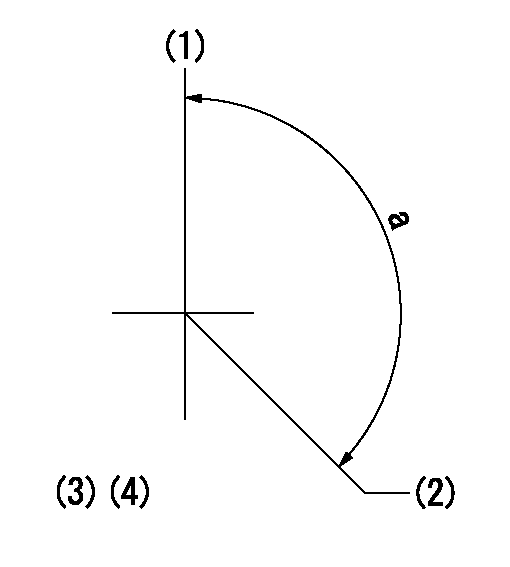

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at rack position = aa, speed = bb.

(2)Clearance between stopper bolt and lever must be cc.

----------

aa=5mm bb=100r/min cc=2+1mm

----------

a=16deg+-5deg b=40deg+-5deg

----------

aa=5mm bb=100r/min cc=2+1mm

----------

a=16deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of spline gear's aligning mark at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=36deg

----------

a=(130deg)

----------

aa=36deg

----------

a=(130deg)

Information:

Table 2

Specifications for Pressure Loss

Direct Injection Fuel Systems

Nozzle pressure must not drop below a gauge reading of

3450 kPa (500 psi) during a 5 second time interval.

Nozzle pressure must drop below a gauge reading of

1380 kPa (200 psi) after an additional 25 second time interval. (1)

( 1 ) A gauge reading of 0 kPa (0 psi) is acceptable after the first 5 second time interval has elapsed.

Illustration 3 g00923167

If the fuel nozzle is not within specifications, stop the test and do not use the fuel nozzle.Valve Opening Pressure Test

Slowly increase the pressure until fluid begins to flow from the tip of the fuel nozzle. Record this pressure as the VOP of the fuel nozzle.

Compare the test results to the specifications for the type of fuel nozzle that is being tested. Refer to Table 3, or Table 4.For precombustion chamber fuel systems, use these specifications:

Table 3

Specifications for Valve Opening Pressure

Precombustion Chamber Fuel Systems

2760 to 5170 kPa (400 to 750 psi)

Illustration 4 g00934108

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.For direct injection fuel systems, use these specifications:

Table 4

Specifications for Valve Opening Pressure

Direct Injection Fuel Systems

16500 to 21400 kPa (2400 to 3100 psi)

Illustration 5 g00923174

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.Tip Leakage Test (Direct Injection Fuel Systems)

Note: Fuel nozzles for precombustion chamber fuel systems can not be tested for tip leakage accurately. Do not perform this test on fuel nozzles for a precombustion