Information injection-pump assembly

ZEXEL

103682-0523

1036820523

Rating:

Cross reference number

ZEXEL

103682-0523

1036820523

Zexel num

Bosch num

Firm num

Name

103682-0523

INJECTION-PUMP ASSEMBLY

14BS PE4-8Z PE

14BS PE4-8Z PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(12.8)

Vist

V

1.44

1.44

1.44

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

733

726

740

Max. variation between cylinders

%

0

-4

4

Basic

*

Remarks

Same Vista as row R (103682-0534)

Same Vista as row R (103682-0534)

Injection quantity adjustment_02

Rack position

(5.6)

Vist

V

2.9

2.8

3

Pump speed

r/min

340

340

340

Average injection quantity

mm3/st.

43.5

38.5

48.5

Max. variation between cylinders

%

0

-14

14

Test data Ex:

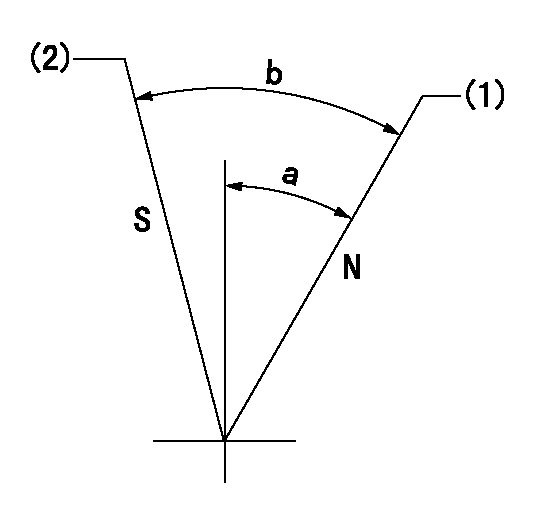

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=29deg+-5deg b=39deg+-5deg

----------

aa=16mm bb=1mm

----------

a=29deg+-5deg b=39deg+-5deg

0000000901

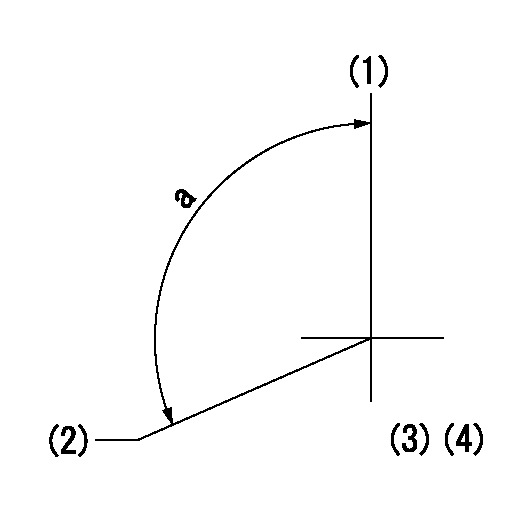

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=25deg

----------

a=(120deg)

----------

aa=25deg

----------

a=(120deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Introduction

This Special Instruction provides detailed instructions on the installation of the sleeve into the compensator group of the 3408E and 3412E Unit Injector Hydraulic Pump. If leaks are experienced at the joint of the compensator and the adapter block, the 174-8943 Sleeve may be installed to improve sealing. The new press fit sleeve contains the O-ring more securely than the original slip fit sleeve.Note: Engines built prior to the serial number break that contain the new sleeve have a "S" stamped at the end of the part number on the serial number plate of the pump. The reworked part numbers appear as "144-0835-06S". Individual Components

Table 1

Quantity Part Number Part Description

1 174-8943 Sleeve

1 135-2652 O-Ring

1 033-6039 O-Ring

6 9X-7680 O-Ring Necessary Tools

One of the following tools may be used to insert the new sleeve into the compensator group.

A 31.750 mm (1.250 inch) diameter flat plate.

The 1P-0467 Drive Plate from 1P-0510 Driver Group .

An acceptable bearing insertion tool.Removal Of The O-Ring Seals

Illustration 1 g00638376

Remove the four bolts (1) from the compensator (2). Remove the compensator and the adapter. Do not adjust the compensator. Refer to Special Instruction, REHS0192-03, step 3 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 2 g00638368

Remove the four O-ring seals (3) from the bottom side of the adapter. Refer to Special Instruction, REHS0192-03, step 4 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 3 g00638372

Remove the four O-ring seals (4) from the two housings. Refer to Special Instruction, REHS0192-03, step 5 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Remove the slip fit sleeve from the compensator housing.Installation Of The Sleeve

Illustration 4 g00637918

(1) Compensator assembly. (2) 174-8943 Sleeve .

Invert the compensator assembly (1). Hold the compensator assembly securely within a vise or a press table.

Start the sleeve (2) by hand into the compensator assembly (1) .Note: It is important that the groove on the outside diameter of the sleeve is oriented toward the O-ring in the joint. If this is not done, there will not be sufficient room to properly seal the O-ring.

Press the sleeve (2) flush with the surface of the compensator assembly (1) using the 1P-0467 Drive Plate or by using an acceptable bearing insertion tool.Installation Of The O-Ring Seals

Illustration 5 g00638368

Install the four O-ring seals (3) on the bottom side of the adapter. Refer to Special Instruction, REHS0192-03, step 16 of procedure for "Assembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 6 g00638372

Install the four O-rings (4) on the two housings. Refer to Special Instruction, REHS0192-03, step 17 of procedure for "Assembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 7 g00638376

Install the compensator assembly (2) and the adapter as a unit vertically so that the O-rings seals are not damaged. Tighten the four bolts (1) to the following torque.Torque for bolts ... 8 1 N

This Special Instruction provides detailed instructions on the installation of the sleeve into the compensator group of the 3408E and 3412E Unit Injector Hydraulic Pump. If leaks are experienced at the joint of the compensator and the adapter block, the 174-8943 Sleeve may be installed to improve sealing. The new press fit sleeve contains the O-ring more securely than the original slip fit sleeve.Note: Engines built prior to the serial number break that contain the new sleeve have a "S" stamped at the end of the part number on the serial number plate of the pump. The reworked part numbers appear as "144-0835-06S". Individual Components

Table 1

Quantity Part Number Part Description

1 174-8943 Sleeve

1 135-2652 O-Ring

1 033-6039 O-Ring

6 9X-7680 O-Ring Necessary Tools

One of the following tools may be used to insert the new sleeve into the compensator group.

A 31.750 mm (1.250 inch) diameter flat plate.

The 1P-0467 Drive Plate from 1P-0510 Driver Group .

An acceptable bearing insertion tool.Removal Of The O-Ring Seals

Illustration 1 g00638376

Remove the four bolts (1) from the compensator (2). Remove the compensator and the adapter. Do not adjust the compensator. Refer to Special Instruction, REHS0192-03, step 3 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 2 g00638368

Remove the four O-ring seals (3) from the bottom side of the adapter. Refer to Special Instruction, REHS0192-03, step 4 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 3 g00638372

Remove the four O-ring seals (4) from the two housings. Refer to Special Instruction, REHS0192-03, step 5 of procedure for "Disassembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Remove the slip fit sleeve from the compensator housing.Installation Of The Sleeve

Illustration 4 g00637918

(1) Compensator assembly. (2) 174-8943 Sleeve .

Invert the compensator assembly (1). Hold the compensator assembly securely within a vise or a press table.

Start the sleeve (2) by hand into the compensator assembly (1) .Note: It is important that the groove on the outside diameter of the sleeve is oriented toward the O-ring in the joint. If this is not done, there will not be sufficient room to properly seal the O-ring.

Press the sleeve (2) flush with the surface of the compensator assembly (1) using the 1P-0467 Drive Plate or by using an acceptable bearing insertion tool.Installation Of The O-Ring Seals

Illustration 5 g00638368

Install the four O-ring seals (3) on the bottom side of the adapter. Refer to Special Instruction, REHS0192-03, step 16 of procedure for "Assembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 6 g00638372

Install the four O-rings (4) on the two housings. Refer to Special Instruction, REHS0192-03, step 17 of procedure for "Assembly of the 144-0835 Unit Injector Hydraulic Pump Group ".

Illustration 7 g00638376

Install the compensator assembly (2) and the adapter as a unit vertically so that the O-rings seals are not damaged. Tighten the four bolts (1) to the following torque.Torque for bolts ... 8 1 N

Have questions with 103682-0523?

Group cross 103682-0523 ZEXEL

Komatsu

103682-0523

INJECTION-PUMP ASSEMBLY