Information injection-pump assembly

ZEXEL

103682-0430

1036820430

KOMATSU

6162731681

6162731681

Rating:

Service parts 103682-0430 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

29.4(300)

15.

NOZZLE SET

Cross reference number

ZEXEL

103682-0430

1036820430

KOMATSU

6162731681

6162731681

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve (drive side)

131425-1620

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

131425-1620

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

16.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

589

584

594

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.1+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

58

53

63

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

17+0.2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

450

450

490

Fixing the lever

*

Rack limit

*

Test data Ex:

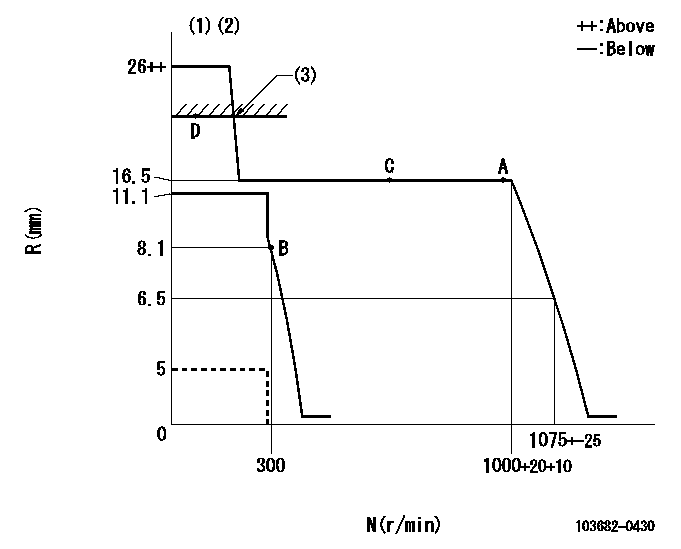

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Deliver without the torque control spring operating.

(3)RACK LIMIT: RAL

----------

K=5 RAL=17+0.2mm

----------

----------

K=5 RAL=17+0.2mm

----------

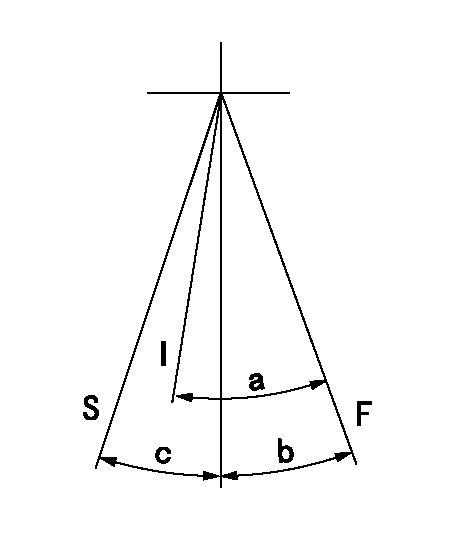

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(33deg)+-5deg b=(13deg)+-5deg c=30deg+-3deg

----------

----------

a=(33deg)+-5deg b=(13deg)+-5deg c=30deg+-3deg

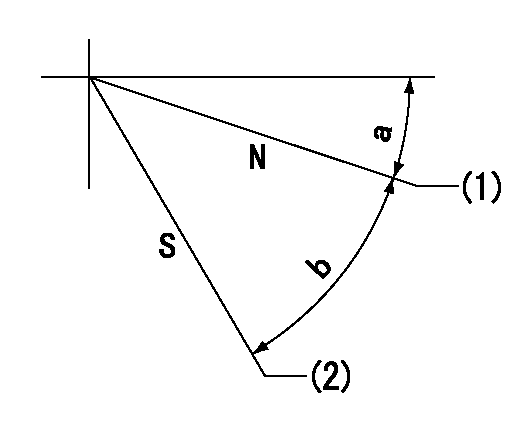

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Clearance between stopper bolt and lever must be aa.

(2)At pump speed bb and rack position cc, set the stopper bolt.

----------

aa=(0.8)mm bb=100r/min cc=5mm

----------

a=24deg+-5deg b=40deg+-5deg

----------

aa=(0.8)mm bb=100r/min cc=5mm

----------

a=24deg+-5deg b=40deg+-5deg

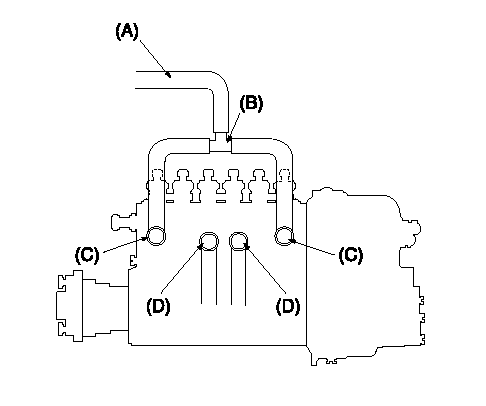

0000001501 Q ADJUSTMENT PIPING

Tester fuel pipe A

(B) branch piping

Fuel inlet C

(D) Overflow valve

Piping at standard injection quantity adjustment

1. Because the pump gallery is divided into two, be careful of the fuel piping at adjustment.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Illustration 1 g00564355

7W-2743 Electronic Speed Switch (ESS)

(1) Push button for Overspeed Verification

(2) Reset button

(3) Overspeed indicator lamp

(4) Seal screw plug for adjusting the engine overspeed

(5) Seal screw plug for adjusting the crank terminate speed

(6) Seal screw plug for adjusting the oil step pressure speed setting The overspeed calibration can increase the overspeed setting or the overspeed calibration can decrease the overspeed setting in order to shut down the engine when the overspeed verification button is pressed. The overspeed setting is correctly made when the engine is running at 75% of the overspeed setting. The engine then shuts down when the overspeed verification button is pressed.Use the following procedure in order to adjust the overspeed setting.

Remove the lockwire and the seal from seal screw plug (4). Remove seal screw plug (4) from the access hole for the overspeed adjustment screw.

Use a small screwdriver to lightly turn the overspeed adjustment screw in the direction of the "MAX" arrow or the clockwise direction. Turn the screw 20 times. The overspeed adjustment screw will vary the setting of a potentiometer that is inside of the ESS. The overspeed adjustment screw will not cause damage to the potentiometer. Also, the screw can not be removed if the screw is turned in the wrong direction.

Run the engine at 75% of the desired overspeed setting rpm. Refer to the Speed Specification Chart.

While the engine is running at 75% of the overspeed setting rpm, press "VERIFY" button (1). While the button is depressed, slowly turn the overspeed adjustment screw in the opposite direction of the "MAX" arrow or the counterclockwise direction until overspeed indicator lamp (3) is lighted. The engine will shut down if the ESS is connected to the fuel shutoff solenoid (FSOS) and the air shutoff solenoid, if equipped.

In order to reset the ESS, press "RESET" button (2). The air shutoff valve must be reset by hand, if equipped.

Slowly turn the overspeed adjustment screw in the clockwise direction for one turn. Repeat Steps 3, 4, and 5. More adjustment may be necessary in order to gain the correct setting. Turn the overspeed adjustment screw in the clockwise direction in order to increase the overspeed setting. Turn the overspeed adjustment screw in the counterclockwise direction in order to decrease the overspeed setting.

When the overspeed setting is correct, install seal screw plug (4) in the access hole for the overspeed adjustment screw. Tighten the screw to a torque of 0.20 0.03 N m (1.8 .3 lb in). Install the lockwire and the seal if the calibration of the crank termination speed and the oil step speed calibration are also complete.