Information injection-pump assembly

BOSCH

9 400 616 362

9400616362

ZEXEL

103682-0420

1036820420

KOMATSU

6162731652

6162731652

Rating:

Service parts 103682-0420 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6164-11-3101

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 362

9400616362

ZEXEL

103682-0420

1036820420

KOMATSU

6162731652

6162731652

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve (drive side)

131425-1620

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

131425-1620

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

535

530

540

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.1+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

58

53

63

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

16+0.2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

390

390

430

Fixing the lever

*

Rack limit

*

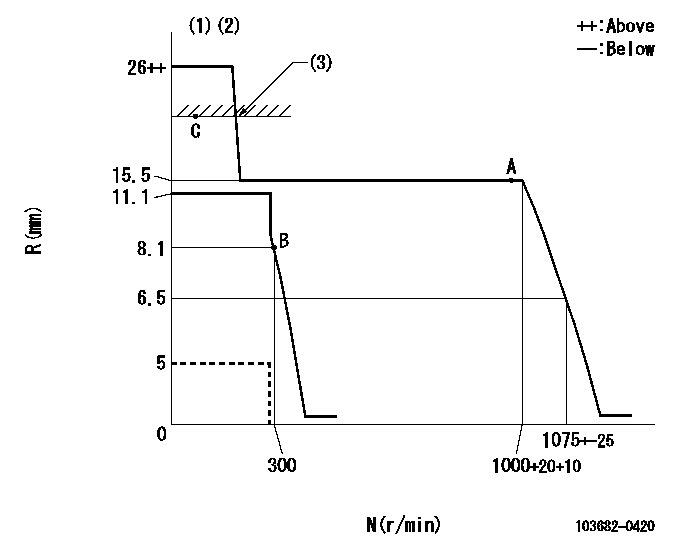

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Deliver without the torque control spring operating.

(3)RACK LIMIT: RAL

----------

K=9 RAL=16+0.2mm

----------

----------

K=9 RAL=16+0.2mm

----------

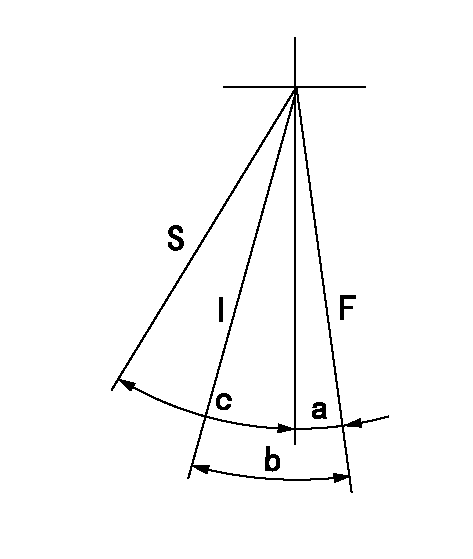

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(16deg)+-5deg b=(42deg)+-5deg c=30deg+-3deg

----------

----------

a=(16deg)+-5deg b=(42deg)+-5deg c=30deg+-3deg

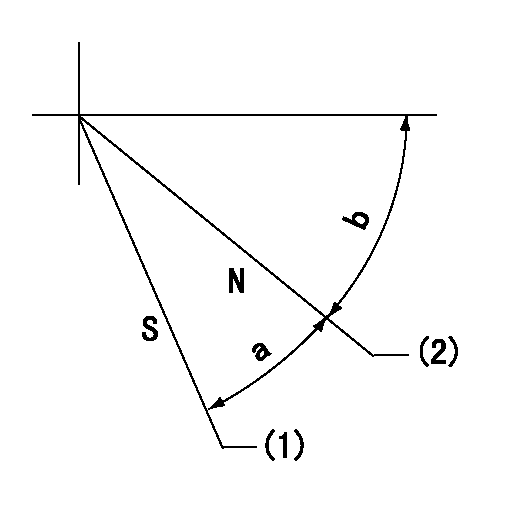

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at speed = aa and rack position = bb.

(2)Clearance between stopper bolt and lever must be cc.

----------

aa=100r/min bb=5mm cc=(0.8)mm

----------

a=40deg+-5deg b=24deg+-5deg

----------

aa=100r/min bb=5mm cc=(0.8)mm

----------

a=40deg+-5deg b=24deg+-5deg

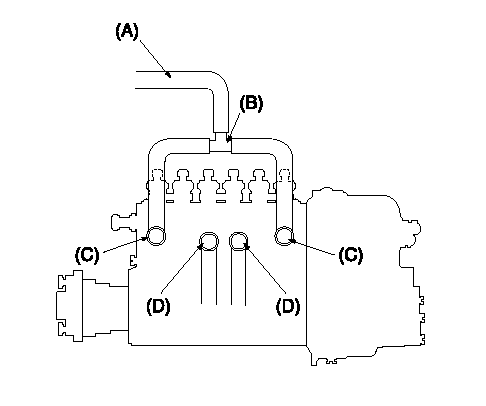

0000001501 Q ADJUSTMENT PIPING

Tester fuel pipe A

(B) branch piping

Fuel inlet C

(D) Overflow valve

Piping at standard injection quantity adjustment

1. Because the pump gallery is divided into two, be careful of the fuel piping at adjustment.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Test 1 - Overspeed Switch (OS)

Table 1

Overspeed Switch (OS)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than 75% Overspeed Verify rpm Press the 75% Verify button No engine shutdown

B 25 + 5 rpm more than 75% Overspeed Verify rpm Press the 75% Verify button Air and fuel shutoff

C Manually reset the air shutoff lever at the top of the air inlet, if equipped. Press the ESS reset button. Test 2 - Emergency Stop Switch (ES)

Table 2

Emergency Stop Switch (ES)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Press the push button for the emergency stop switch Air and fuel shutoff

B Manually reset the air shutoff lever at the top of the air inlet, if equipped. Turn ES switch in the dirction that is shown on the face of the push button in order to reset the switch. Test 3 - Normal Stop Switch (NSS)

Table 3

Normal Stop Switch (NSS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Push the normal stop switch (NSS) Fuel shutoff Test 4 - Water Temperature Contactor Switch

Table 4

Water Temperature Contactor Switch (WTS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals TS-2 and TS-7. Fuel shutoff

B Remove the jumper from terminals TS-2 and TS-7. Test 5 - Oil Pressure Switch (OPS1)

Table 5

Oil Pressure Switch (OPS1)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals OPS1-1 and OPS1-3. Fuel shutoff

B Remove the jumper from terminals OPS1-1 and OPS1-3. Test 6 - Oil Pressure Switch (OPS2)

Table 6

Oil Pressure Switch (OPS2)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. No engine shutdown.

B 25 + 5 rpm more than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. Fuel shutoff 9 seconds after the oil step speed is reached.

C Remove the jumper from across terminals OPS2-1 and OPS2-3.

Table 1

Overspeed Switch (OS)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than 75% Overspeed Verify rpm Press the 75% Verify button No engine shutdown

B 25 + 5 rpm more than 75% Overspeed Verify rpm Press the 75% Verify button Air and fuel shutoff

C Manually reset the air shutoff lever at the top of the air inlet, if equipped. Press the ESS reset button. Test 2 - Emergency Stop Switch (ES)

Table 2

Emergency Stop Switch (ES)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Press the push button for the emergency stop switch Air and fuel shutoff

B Manually reset the air shutoff lever at the top of the air inlet, if equipped. Turn ES switch in the dirction that is shown on the face of the push button in order to reset the switch. Test 3 - Normal Stop Switch (NSS)

Table 3

Normal Stop Switch (NSS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Push the normal stop switch (NSS) Fuel shutoff Test 4 - Water Temperature Contactor Switch

Table 4

Water Temperature Contactor Switch (WTS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals TS-2 and TS-7. Fuel shutoff

B Remove the jumper from terminals TS-2 and TS-7. Test 5 - Oil Pressure Switch (OPS1)

Table 5

Oil Pressure Switch (OPS1)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals OPS1-1 and OPS1-3. Fuel shutoff

B Remove the jumper from terminals OPS1-1 and OPS1-3. Test 6 - Oil Pressure Switch (OPS2)

Table 6

Oil Pressure Switch (OPS2)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. No engine shutdown.

B 25 + 5 rpm more than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. Fuel shutoff 9 seconds after the oil step speed is reached.

C Remove the jumper from across terminals OPS2-1 and OPS2-3.