Information injection-pump assembly

BOSCH

9 400 611 949

9400611949

ZEXEL

103662-3360

1036623360

Rating:

Service parts 103662-3360 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-13-8902

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 949

9400611949

ZEXEL

103662-3360

1036623360

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

131425-2020

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

18.3

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

499

494

504

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

92

92

Boost pressure

mmHg

690

690

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.5+-0.

5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

44.5

39.5

49.5

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

485

485

505

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-4.4

Boost pressure

kPa

16

13.3

18.7

Boost pressure

mmHg

120

100

140

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1(18.3)

Boost pressure

kPa

78.6

71.9

85.3

Boost pressure

mmHg

590

540

640

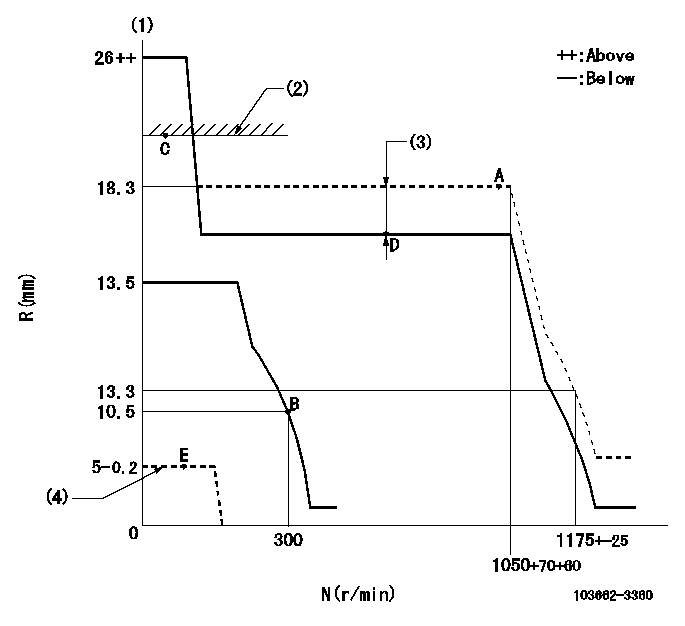

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

(4)Stop lever at stopping (with the speed lever at full, 0 boost)

----------

K=19 BCL=4.4+-0.1mm

----------

----------

K=19 BCL=4.4+-0.1mm

----------

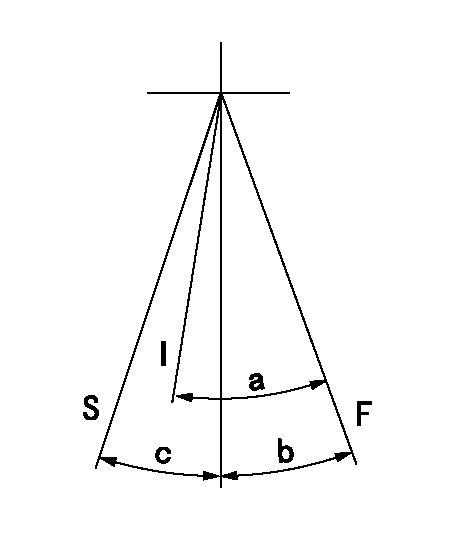

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=37deg+-5deg b=28deg+-5deg c=30deg+-3deg

----------

----------

a=37deg+-5deg b=28deg+-5deg c=30deg+-3deg

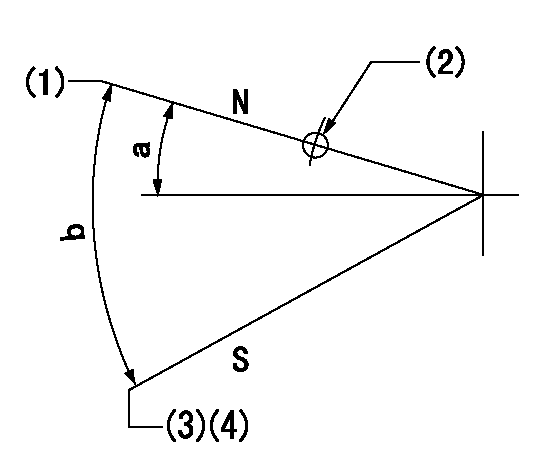

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)The clearance from the set screw must be aa.

(2)Use the hole at R = bb

(3)Set the screw so that speed = cc, rack position = dd

(4)At speed lever full, 0 boost

----------

aa=2+1mm bb=40mm cc=100r/min dd=5-0.2mm

----------

a=16deg+-5deg b=40deg+-5deg

----------

aa=2+1mm bb=40mm cc=100r/min dd=5-0.2mm

----------

a=16deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

1. Disconnect boost hose (2) at fuel ratio control (1).2. Remove lockwire (3) and the seal from the bolts.3. Remove the two bolts that hold fuel ratio control (1).4. Pull up on the fuel ratio control, and move it toward the front of the engine so the valve on the fuel ratio will disengage with the groove (slot) in the governor collar. Remove the fuel ratio control and gasket. The following steps are for installation of the fuel ratio control.5. Install a new gasket on fuel ratio control (1).6. Engage valve (4) with the groove (slot) in collar (5) for the governor.7. Install the bolts that hold fuel ratio control (1) to the governor plate.8. Connect boost hose (2) to the fuel ratio control.9. Install new lockwire (3) and seal. See Fuel Rack Setting in Testing And Adjusting.10. Lower the hoods.Disassemble Fuel Ratio Control

Start By:a. remove fuel ratio control The illustrations which follow show a different design fuel ratio control. However, the service procedure is the same. 1. Remove two bolts (1) and cover (2). 2. Remove valve assembly (3).3. Remove seal (4) and the O-ring seal from the valve assembly.4. Remove retainer (5) and two springs (6). 5. Remove the three bolts from the cover. Remove cover (12) and gasket (11).6. Remove valve (13), diaphragm (8), retainer (9) and spring (10).7. Remove pin (14) from valve (13).8. Remove cover (7) from the valve.Assemble Fuel Ratio Control

The illustrations which follow show a different design fuel ratio control. However, the service procedure is the same. 1. Put clean SAE 30 Oil on the seal. Install seal (1) in cover (2) with the lip of the seal toward the inside of the cover. 2. Install valve (3) in cover (2).3. Install the pin that holds the cover on the valve. 4. Install the spring and the retainer in cover (6).5. Install diaphragm (5) on valve assembly (4) and in the cover.6. Install cover (8). Install three bolts (7) that hold the cover in position. 7. Put clean SAE 30 Oil on the seal and the ring seal. Install seals (11) on the valve.8. Install two springs (12), retainer (13) and valve assembly (10).9. Install housing (9) and the bolts.

Correct adjustment must be made to fuel ratio control before installation. See the topic "Adjustment Of Air Fuel Ratio Control" in Testing & Adjusting.

End By:a. install fuel ratio control

Start By:a. remove fuel ratio control The illustrations which follow show a different design fuel ratio control. However, the service procedure is the same. 1. Remove two bolts (1) and cover (2). 2. Remove valve assembly (3).3. Remove seal (4) and the O-ring seal from the valve assembly.4. Remove retainer (5) and two springs (6). 5. Remove the three bolts from the cover. Remove cover (12) and gasket (11).6. Remove valve (13), diaphragm (8), retainer (9) and spring (10).7. Remove pin (14) from valve (13).8. Remove cover (7) from the valve.Assemble Fuel Ratio Control

The illustrations which follow show a different design fuel ratio control. However, the service procedure is the same. 1. Put clean SAE 30 Oil on the seal. Install seal (1) in cover (2) with the lip of the seal toward the inside of the cover. 2. Install valve (3) in cover (2).3. Install the pin that holds the cover on the valve. 4. Install the spring and the retainer in cover (6).5. Install diaphragm (5) on valve assembly (4) and in the cover.6. Install cover (8). Install three bolts (7) that hold the cover in position. 7. Put clean SAE 30 Oil on the seal and the ring seal. Install seals (11) on the valve.8. Install two springs (12), retainer (13) and valve assembly (10).9. Install housing (9) and the bolts.

Correct adjustment must be made to fuel ratio control before installation. See the topic "Adjustment Of Air Fuel Ratio Control" in Testing & Adjusting.

End By:a. install fuel ratio control