Information injection-pump assembly

ZEXEL

103662-3182

1036623182

Rating:

Service parts 103662-3182 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-12-3403

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

ZEXEL

103662-3182

1036623182

Zexel num

Bosch num

Firm num

Name

103662-3182

INJECTION-PUMP ASSEMBLY

SA6D170A 14BS PE4-8Z PE

SA6D170A 14BS PE4-8Z PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

133424-0420

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

17.3

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

469

464

474

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

58.7

58.7

Boost pressure

mmHg

440

440

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.9+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

39

34

44

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

13.7

Boost pressure

kPa

9.3

8

10.6

Boost pressure

mmHg

70

60

80

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

18.1

Boost pressure

kPa

45.3

45.3

45.3

Boost pressure

mmHg

340

340

340

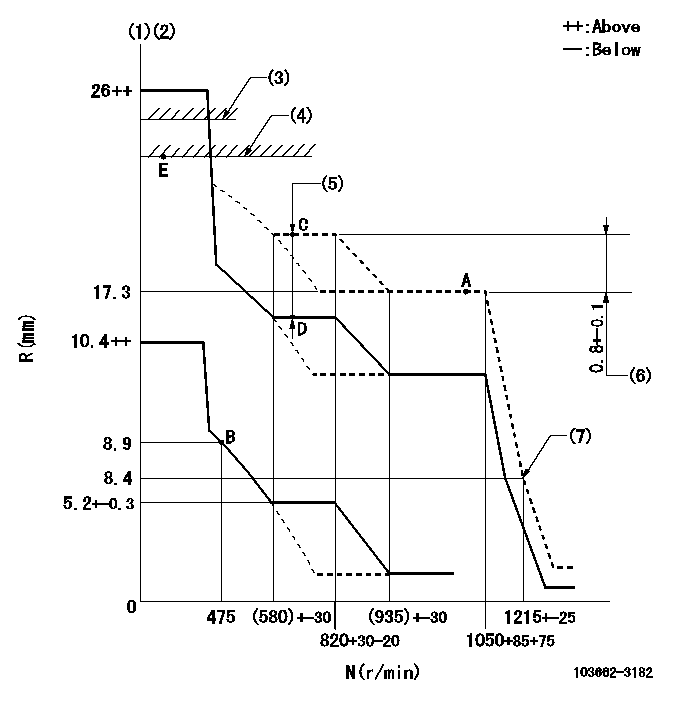

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Minimum - maximum speed specification

(2)Target notch: K

(3)Stop lever's normal position setting: R1

(4)RACK LIMIT: RAL

(5)Boost compensator stroke: BCL

(6)Rack difference between N = N1 and N = N2

(7)Idle sub spring setting: L1.

----------

K=20 R1=19.2+0.5mm RAL=18.6+0.2mm BCL=4.4+0.1mm N1=1050r/min N2=750r/min L1=8.4-0.5mm

----------

----------

K=20 R1=19.2+0.5mm RAL=18.6+0.2mm BCL=4.4+0.1mm N1=1050r/min N2=750r/min L1=8.4-0.5mm

----------

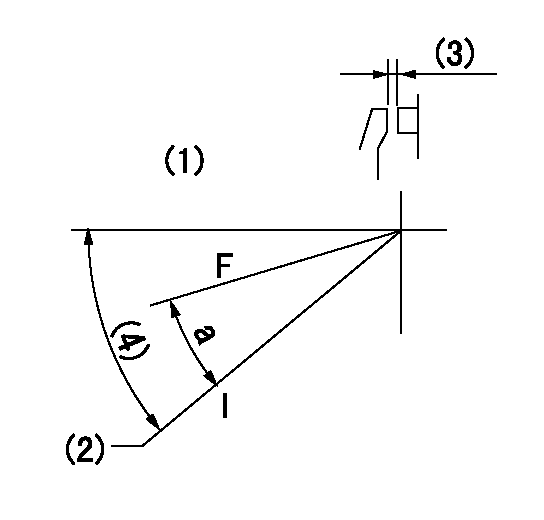

Speed control lever angle

F:Full speed

----------

----------

a=(30deg)+-5deg

----------

----------

a=(30deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Clearance is bb from where contacts inner stopper.

(4)Actual measurement

----------

aa=80mm bb=(2)mm

----------

a=(16.5deg)+-5deg

----------

aa=80mm bb=(2)mm

----------

a=(16.5deg)+-5deg

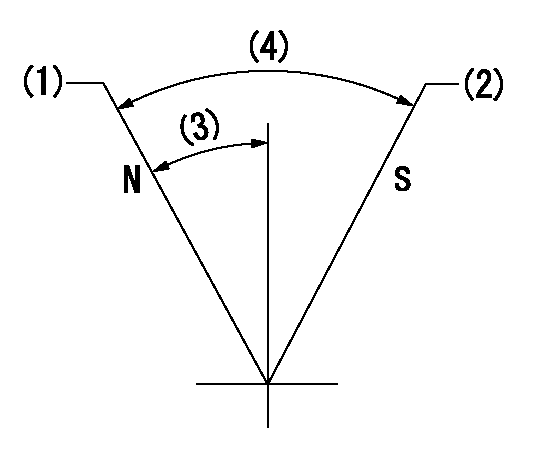

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb, pump speed cc

(3)(Actual measurement)

(4)(Actual measurement)

----------

aa=19.2+0.5mm bb=2-0.2mm cc=0r/min

----------

----------

aa=19.2+0.5mm bb=2-0.2mm cc=0r/min

----------

Information:

1. Disconnect fuel lines (1) from fuel transfer pump (3). Remove bolts (2). Remove fuel transfer pump (3). Remove gasket from fuel transfer pump.2. Install a new gasket on fuel transfer pump (3). Install fuel transfer pump on rear plate with the bolts (2) that hold it. Connect fuel lines (1) to the fuel transfer pump.Disassemble Fuel Transfer Pump

Start By:a. remove fuel transfer pump 1. Remove tachometer drive (3) from transfer pump cover (4).2. Remove bolts (1). Make a separation between cover (4) and pump body (2). 3. Remove lip-type seal (6) from the cover. Remove plug (5), seal, spring and plunger (bypass valve) from the cover. 4. Remove nut (10) from shaft (7). Remove gear (9) and key (11).5. Remove shaft (7) and gear (8) as a unit. Remove gear (8) from drive shaft (7) with a press.6. Remove idler gear (12). 7. Remove bushing (14), two lip-type seals and the bottom bearing from pump body (1).8. Remove check valve (13). Assemble Fuel Transfer Pump

1. Install bushing (4) in body (3) with Tooling (B). The bushing must not be extended above the (gear) surface of the body.2. Install the check valve in the body with Tooling (A).3. Install lip-type seal (5) with Tooling (C). Install the seal until it is 24.6 0.5 mm (97 .02) from the bottom surface of body (3) and with the lip toward bushing (4) as shown.4. Install lip-type seal (6) with Tooling (D). Install the seal until it is 14.2 0.5 mm (.56 .02 in) from the bottom surface of body (3) and with the lip away from seal (5) as shown.5. Install bearing (7) in body (3) with Tooling (E). The bearing must be even with the surface of the pump body. 6. Heat gear (8) to a maximum temperature of 316°C (600°F). Install gear (8) on shaft (11) until dimension (X) is 49.71 0.25 mm (1.957 0.10 in).7. Install the drive shaft and gear in body (3). Install key, gear (10) and nut (9). Tighten the nut to a torque of 28 7 N m (22 5 lb ft).8. Install idler gear (12) in body (3).9. Install lip-type seal (2) with Tooling (C). Install the seal until it is 3.8 0.5 mm (.15 .02 in) from the top surface of cover (1) with the lip toward the inside as shown. 10. Install plunger (14) (bypass valve), spring (15), seal plug (13) in pump cover (1). Tighten plug (13) to a torque of 28 4 N m (27 3 lb ft).11. Put 7M-7260 Liquid Gasket Material on the surface of cover (1). Install cover (1) on pump body.

Do not let the liquid gasket enter the pump.

The drive shaft must turn freely after the bolts that hold the transfer pump together are tightened.12. Install tachometer drive on transfer pump cover (1).End By:a. install fuel transfer pump

Start By:a. remove fuel transfer pump 1. Remove tachometer drive (3) from transfer pump cover (4).2. Remove bolts (1). Make a separation between cover (4) and pump body (2). 3. Remove lip-type seal (6) from the cover. Remove plug (5), seal, spring and plunger (bypass valve) from the cover. 4. Remove nut (10) from shaft (7). Remove gear (9) and key (11).5. Remove shaft (7) and gear (8) as a unit. Remove gear (8) from drive shaft (7) with a press.6. Remove idler gear (12). 7. Remove bushing (14), two lip-type seals and the bottom bearing from pump body (1).8. Remove check valve (13). Assemble Fuel Transfer Pump

1. Install bushing (4) in body (3) with Tooling (B). The bushing must not be extended above the (gear) surface of the body.2. Install the check valve in the body with Tooling (A).3. Install lip-type seal (5) with Tooling (C). Install the seal until it is 24.6 0.5 mm (97 .02) from the bottom surface of body (3) and with the lip toward bushing (4) as shown.4. Install lip-type seal (6) with Tooling (D). Install the seal until it is 14.2 0.5 mm (.56 .02 in) from the bottom surface of body (3) and with the lip away from seal (5) as shown.5. Install bearing (7) in body (3) with Tooling (E). The bearing must be even with the surface of the pump body. 6. Heat gear (8) to a maximum temperature of 316°C (600°F). Install gear (8) on shaft (11) until dimension (X) is 49.71 0.25 mm (1.957 0.10 in).7. Install the drive shaft and gear in body (3). Install key, gear (10) and nut (9). Tighten the nut to a torque of 28 7 N m (22 5 lb ft).8. Install idler gear (12) in body (3).9. Install lip-type seal (2) with Tooling (C). Install the seal until it is 3.8 0.5 mm (.15 .02 in) from the top surface of cover (1) with the lip toward the inside as shown. 10. Install plunger (14) (bypass valve), spring (15), seal plug (13) in pump cover (1). Tighten plug (13) to a torque of 28 4 N m (27 3 lb ft).11. Put 7M-7260 Liquid Gasket Material on the surface of cover (1). Install cover (1) on pump body.

Do not let the liquid gasket enter the pump.

The drive shaft must turn freely after the bolts that hold the transfer pump together are tightened.12. Install tachometer drive on transfer pump cover (1).End By:a. install fuel transfer pump

Have questions with 103662-3182?

Group cross 103662-3182 ZEXEL

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

103662-3182

INJECTION-PUMP ASSEMBLY

SA6D170A

SA6D170A