Information injection-pump assembly

ZEXEL

103662-3100

1036623100

KOMATSU

6162731570

6162731570

Rating:

Service parts 103662-3100 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6162-13-3902

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Cross reference number

ZEXEL

103662-3100

1036623100

KOMATSU

6162731570

6162731570

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Outer diameter - inner diameter - length (mm) mm 8-4-1500

Overflow valve

133424-0420

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

16.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

473.5

468.5

478.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.1+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

48

44

52

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

18

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

488

483

493

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

14

Boost pressure

kPa

12

12

12

Boost pressure

mmHg

90

90

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

18

Boost pressure

kPa

41.3

38.6

44

Boost pressure

mmHg

310

290

330

Test data Ex:

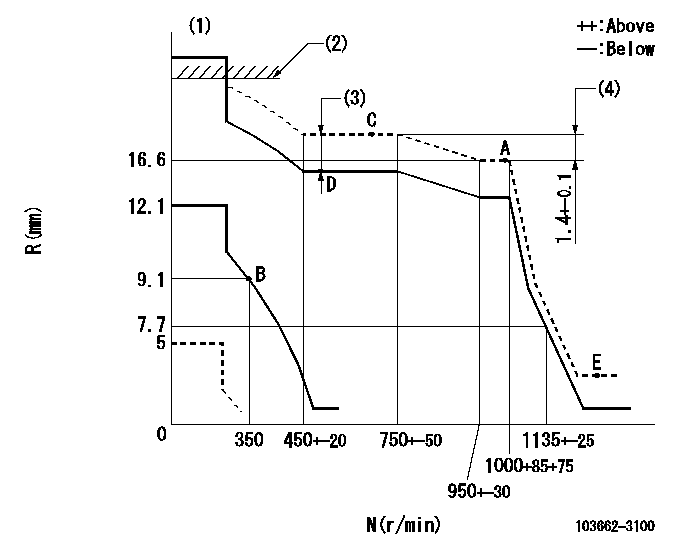

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch: K

(2)RACK LIMIT: RAL

(3)Boost compensator stroke: BCL

(4)Rack difference between N = N1 and N = N2

----------

K=10 RAL=20+0.2mm BCL=4+-0.1mm N1=1000r/min N2=700r/min

----------

----------

K=10 RAL=20+0.2mm BCL=4+-0.1mm N1=1000r/min N2=700r/min

----------

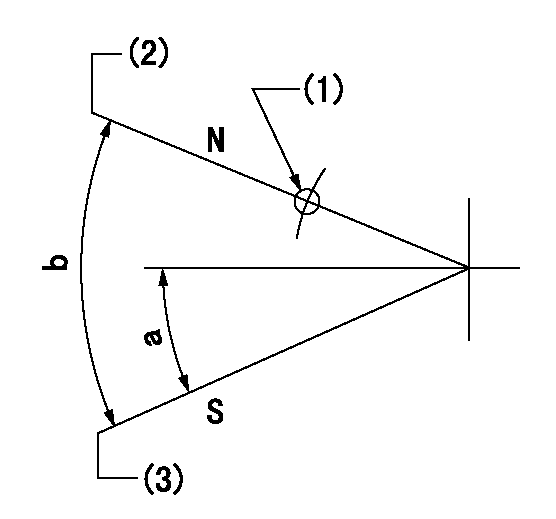

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=38deg+-5deg

----------

----------

a=17deg+-5deg b=38deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)The clearance from the set screw must be bb.

(3)Set the screw at speed = cc and rack position = dd.

----------

aa=44mm bb=2+1mm cc=100r/min dd=5mm

----------

a=20deg+-5deg b=40deg+-5deg

----------

aa=44mm bb=2+1mm cc=100r/min dd=5mm

----------

a=20deg+-5deg b=40deg+-5deg

Information:

Start By:a. remove valve covers 1. Use Tool (A) to disconnect fuel injection line (1) at both ends. Remove the fuel injection line from the engine. 2. Use Tool (B) to remove retainer (2) from the adapter.3. Remove the fuel injection nozzles with Tooling (C) as follows:a. Install the 6V-6983 Adapter and the 8T-3199 Screw into nozzle assembly (3).b. Install the 8T-3198 Tube over the 8T-3199 Screw.c. Use the 1B-4206 Nut on the 8T-3199 Screw to pull the fuel injection nozzle from the adapter.4. Remove compression seal (4) and carbon dam seal (8) from fuel injection nozzle (3).5. Use Tool (D) to remove adapter (6) from the cylinder head.6. Remove gasket (7) and seal (5) from adapter (6). The following steps are for installation of the fuel injection nozzles and adapters.7. Use Tool (E) to clean the bore in adapter (6). Use an open end wrench or tap driver to turn Tool (E).8. Inspect seal (5) for damage or wear. Replace the seal if necessary.9. Put washer (7) and seal (5) in position on adapter (6).10. Put liquid soap in the bores of the cylinder head and on seals (5) in the adapters.11. Put 5P-3931 Anti-Seize Compound on the threads of adapter (6), and install the adapter in the cylinder head assembly.12. Use Tool (D), and tighten the adapter to a torque of 205 14 N m (150 10 lb ft).

Make sure the correct compression seal washer (4) is used when the nozzle assembly is installed in the adapter. Only copper washers are to be used with this adapter.

13. Install compression seal washer (4), and use Tool (F) to install carbon dam seal (8) on the fuel injection nozzle.14. Put fuel injection nozzle (3) in position in the adapter, and install retainer (2).15. Use Tool (B) to tighten retainer (2) to a torque of 48 7 N m (35 5 lb ft).16. Install fuel line (1). Tighten the nuts on the fuel line with Tool (A) to a torque of 40 7 N m (30 5 lb ft).End By:a. install valve covers

Make sure the correct compression seal washer (4) is used when the nozzle assembly is installed in the adapter. Only copper washers are to be used with this adapter.

13. Install compression seal washer (4), and use Tool (F) to install carbon dam seal (8) on the fuel injection nozzle.14. Put fuel injection nozzle (3) in position in the adapter, and install retainer (2).15. Use Tool (B) to tighten retainer (2) to a torque of 48 7 N m (35 5 lb ft).16. Install fuel line (1). Tighten the nuts on the fuel line with Tool (A) to a torque of 40 7 N m (30 5 lb ft).End By:a. install valve covers