Information injection-pump assembly

ZEXEL

101902-0000

1019020000

ISUZU

1156010271

1156010271

Rating:

Cross reference number

ZEXEL

101902-0000

1019020000

ISUZU

1156010271

1156010271

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

R: right hand row, L: left hand row 1L4R9L8R 5L2R11L1 0R3L6R7L

R: right hand row, L: left hand row 1L4R9L8R 5L2R11L1 0R3L6R7L

Pre-stroke

mm

4.4

4.35

4.45

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 15 14.5 15.5

Cal 1-4 deg. 15 14.5 15.5

Difference between angles 2

Cal 1-9 deg. 60 59.5 60.5

Cal 1-9 deg. 60 59.5 60.5

Difference between angles 3

Cal 1-8 deg. 75 74.5 75.5

Cal 1-8 deg. 75 74.5 75.5

Difference between angles 4

Cal 1-5 deg. 120 119.5 120.5

Cal 1-5 deg. 120 119.5 120.5

Difference between angles 5

Cyl.1-2 deg. 135 134.5 135.5

Cyl.1-2 deg. 135 134.5 135.5

Difference between angles 6

Cal 1-11 deg. 180 179.5 180.5

Cal 1-11 deg. 180 179.5 180.5

Difference between angles 7

Cal 1-10 deg. 195 194.5 195.5

Cal 1-10 deg. 195 194.5 195.5

Difference between angles 8

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 9

Cal 1-6 deg. 255 254.5 255.5

Cal 1-6 deg. 255 254.5 255.5

Difference between angles 10

Cal 1-7 deg. 300 299.5 300.5

Cal 1-7 deg. 300 299.5 300.5

Difference between angles 11

Cal 1-12 deg. 315 314.5 315.5

Cal 1-12 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

128.5

127.5

129.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10

8.6

11.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

8.1

Boost pressure

kPa

10.7

8

13.4

Boost pressure

mmHg

80

60

100

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

10.2

Boost pressure

kPa

56

45.3

66.7

Boost pressure

mmHg

420

340

500

Test data Ex:

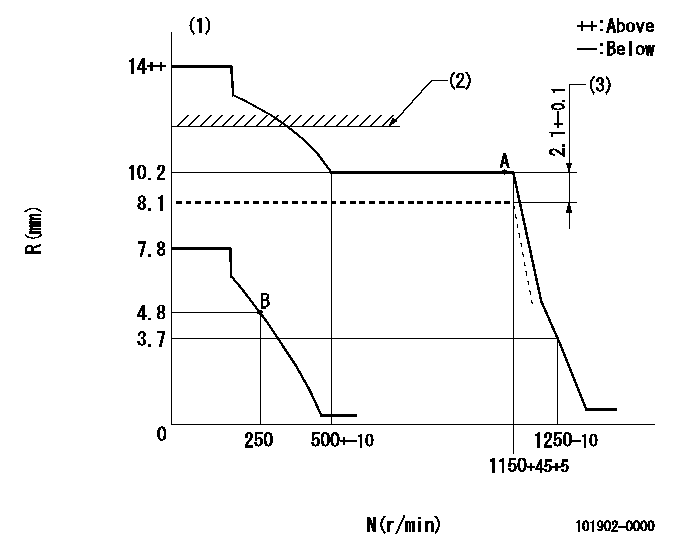

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Excessive fuel setting for starting using boost compensator lever: SXL

(3)Boost compensator stroke

----------

K=5 SXL=10.4+0.2mm

----------

----------

K=5 SXL=10.4+0.2mm

----------

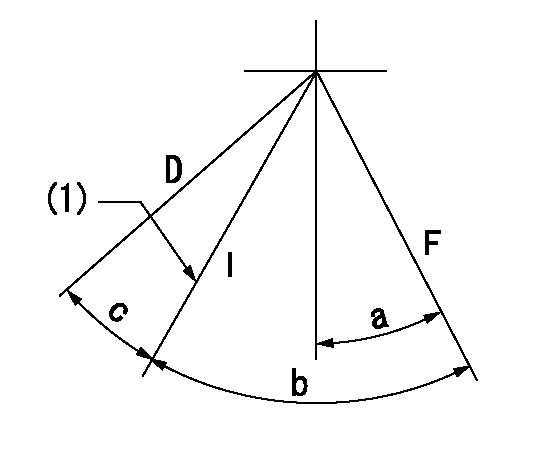

Speed control lever angle

F:Full speed

I:Idle

D:Dead point

(1)Stopper bolt setting

----------

----------

a=22deg+-5deg b=32deg+-5deg c=0deg+6deg

----------

----------

a=22deg+-5deg b=32deg+-5deg c=0deg+6deg

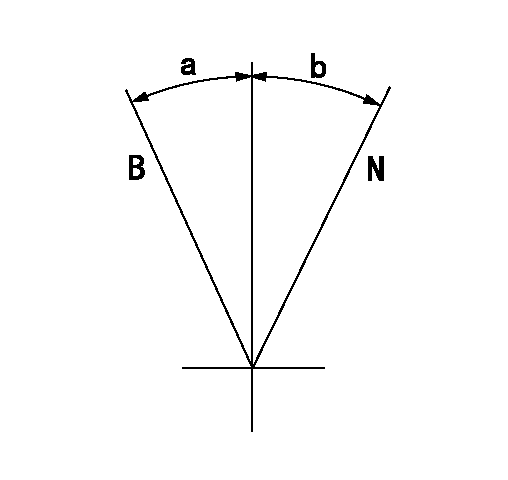

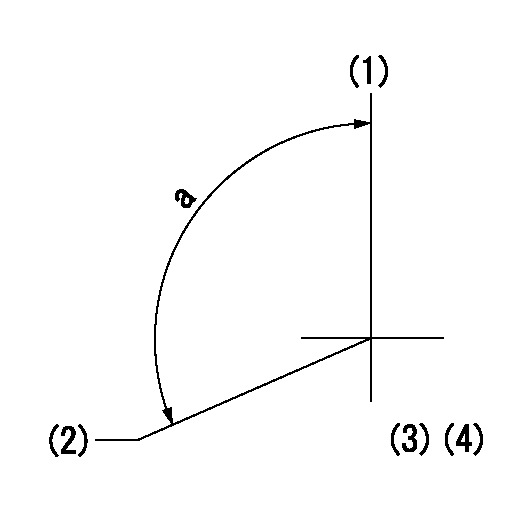

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(10deg) b=(15deg)

----------

----------

a=(10deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear shaft's key groove at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(120deg)

----------

aa=16deg

----------

a=(120deg)

Information:

Core Management

Please refer to the Caterpillar® Core Management Information System (CMIS 2) Parts Information application describing all reman part/CAF and related information. Also refer to other CMIS 2 inquiry applications such as Customer Profiles, Inspection Reason Codes, Inspection Line Inquiry, Add Charge Information, Entitlement Activity, Entitlement Inquiry, CCR Inquiry, CCR Entry, Shipment Processing; Process Packaging Grief; and Reporting to properly manage core returns and monitor inspection performance. This information will be available to all dealers worldwide after your CMIS 2 conversion date. In the meantime, please continue to use the current CMIS Entitlement Parts Inquiry Screen describing the list of parts in a Core Acceptability Family (CAF) and related part number detail.

For the latest updates of Reman Policies and Core Management (SELD0122), Core Management Systems & Operations Procedures (SELD0040), and Shipping Instructions (SELD0039), go to the Reman Dealer website https://reman.cat.com

If you have any questions regarding core return processing, feel free to call Corinth toll free at (800) 537-2928. For assistance with technical questions, call the Peoria Reman Customer Satisfaction Hot Line also toll free at (888) 88-REMAN or use our E-mail address--Reman_Help.

RWSmith

Remanufactured Products Group

LC-2148 (309) 675-5445