Information injection-pump assembly

BOSCH

9 400 616 238

9400616238

ZEXEL

101901-4291

1019014291

ISUZU

1156017020

1156017020

Rating:

Service parts 101901-4291 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

4.

SUPPLY PUMP

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 616 238

9400616238

ZEXEL

101901-4291

1019014291

ISUZU

1156017020

1156017020

Zexel num

Bosch num

Firm num

Name

101901-4291

9 400 616 238

1156017020 ISUZU

INJECTION-PUMP ASSEMBLY

8PC1 K 14BG INJECTION PUMP ASSY PE8A PE

8PC1 K 14BG INJECTION PUMP ASSY PE8A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

R: right hand row, L: left hand row 1L-8R-7L -3L-6R-5 L-4R-2R

R: right hand row, L: left hand row 1L-8R-7L -3L-6R-5 L-4R-2R

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Opposite to the driving side NO.1

Opposite to the driving side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-4 deg. 270 269.5 270.5

Cal 1-4 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

86.1

85.1

87.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

3.3

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.6

7.2

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.5

2

3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

6

6

6

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

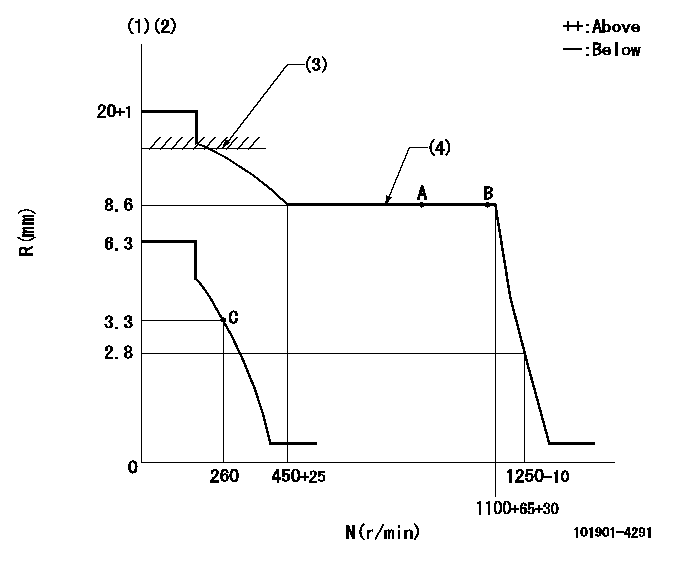

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Do not operate the damper spring.

(3)RACK CAP: R1

(4)The torque control spring does not operate.

----------

K=20 R1=(17.5)mm

----------

----------

K=20 R1=(17.5)mm

----------

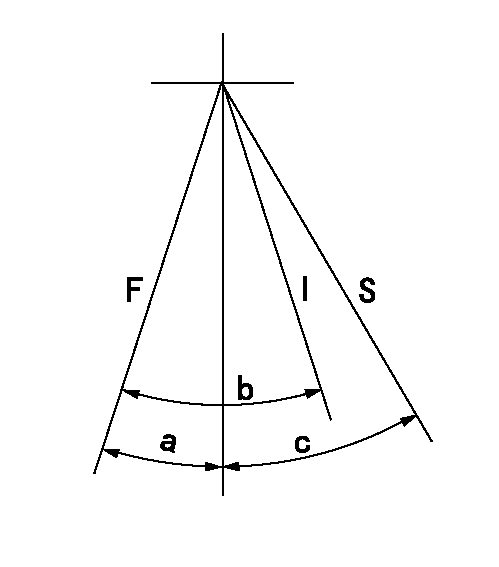

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=15deg+-3deg b=29deg+-5deg c=32deg+-3deg

----------

----------

a=15deg+-3deg b=29deg+-5deg c=32deg+-3deg

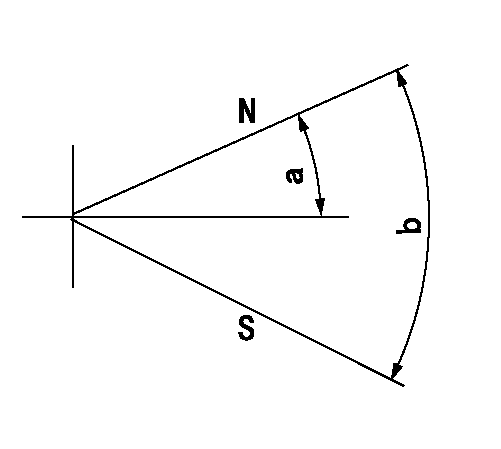

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=300r/min Ra=3.3mm

----------

----------

N1=300r/min Ra=3.3mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(40deg)

----------

aa=15deg

----------

a=(40deg)

Information:

1. If necessary, remove the injector clamp bolt and clamp.

Illustration 1. Remove Clamp Bolt And Clamp.2. Remove jumper tube by removing two socket head cap screws on one end and loosening the tube nut on the other end. Refer to Illustrations 2 and 3.

Illustration 2. Remove Two Cap Screws.

Illustration 3. Loosen Tube Nut.

Make sure the small seat, shown in Illustration 4, is removed. Do not allow the seat to fall into any engine cavity, which could result in damage if unintentionally left inside the engine.Also, make sure the jumper tube is kept clean at all times. Dirt or other debris can get into the engine with this tube removed and cause possible damage.

Illustration 4. Do Not Lose Or Misplace Tube Seat.3. Remove four bolts and rocker arm assembly.

Illustration 5. Remove Rocker Arm Assembly.4. Remove inlet manifold bolt, as shown in Illustration 6.

Illustration 6. Remove Manifold Bolt.5. Remove the unit injector.6. Install a new injector brass sleeve or inspect and ream the existing sleeves as outlined in Tool Operating Manual NEHS0675. It is not necessary to ream new sleeves when using this procedure.7. Install the unit injector.

Do not install the injectors "off-engine" because the injector tip will protrude from the head and be subject to damage. If the injectors are installed off-engine, make sure the bottom surface of the head is raised off the surface of the work bench.

8. Install the injector forcing cover (8). Make sure the extending portion (small dowel) is in the oil supply hole of the injector. Also make sure wear button (10) is in place.

Illustration 7. Install Injector Forcing Cover (8) With Wear Button (10).9. Place a small amount of 4C-5591 Thread Lubricant on top of the injector forcing cover's wear button (10) and on the threads of forcing bolt (4).

Complete lubrication of the wear button and forcing bolt must be maintained for each injector seating procedure. Failure to relubricate each part before seating the next injector may cause premature wear or tool damage. Also, make sure the forcing bolt turns freely and does not have any damaged threads.

Illustration 8. Put A Small Amount Of Thread Lubricant On Wear Button.10. Install the forcing bridge with three 7X-0457 Bolts (5) and three 9M-1974 Hard Washers (6). Put the two long legs of the forcing bridge in the two rocker arm shaft support holes closest to the injector. The short leg of the forcing bridge sits on the intake manifold bolt boss.

Illustration 9. Install Forcing Bridge.11. Tighten forcing bridge mounting bolts (5) to 28 7 N m, 2.9 0.7 meter kg, (21 5 lb. ft.).

Damage to the head could occur if bridge mounting bolts (5) are not tightened to the specified torque.

Illustration 10. Tighten Forcing Bridge Bolts.12. Tighten the forcing bolt finger tight.13. Use a 9U-5019 Torque Wrench and tighten the forcing bolts to 34 1.4 N m, 3.5

Illustration 1. Remove Clamp Bolt And Clamp.2. Remove jumper tube by removing two socket head cap screws on one end and loosening the tube nut on the other end. Refer to Illustrations 2 and 3.

Illustration 2. Remove Two Cap Screws.

Illustration 3. Loosen Tube Nut.

Make sure the small seat, shown in Illustration 4, is removed. Do not allow the seat to fall into any engine cavity, which could result in damage if unintentionally left inside the engine.Also, make sure the jumper tube is kept clean at all times. Dirt or other debris can get into the engine with this tube removed and cause possible damage.

Illustration 4. Do Not Lose Or Misplace Tube Seat.3. Remove four bolts and rocker arm assembly.

Illustration 5. Remove Rocker Arm Assembly.4. Remove inlet manifold bolt, as shown in Illustration 6.

Illustration 6. Remove Manifold Bolt.5. Remove the unit injector.6. Install a new injector brass sleeve or inspect and ream the existing sleeves as outlined in Tool Operating Manual NEHS0675. It is not necessary to ream new sleeves when using this procedure.7. Install the unit injector.

Do not install the injectors "off-engine" because the injector tip will protrude from the head and be subject to damage. If the injectors are installed off-engine, make sure the bottom surface of the head is raised off the surface of the work bench.

8. Install the injector forcing cover (8). Make sure the extending portion (small dowel) is in the oil supply hole of the injector. Also make sure wear button (10) is in place.

Illustration 7. Install Injector Forcing Cover (8) With Wear Button (10).9. Place a small amount of 4C-5591 Thread Lubricant on top of the injector forcing cover's wear button (10) and on the threads of forcing bolt (4).

Complete lubrication of the wear button and forcing bolt must be maintained for each injector seating procedure. Failure to relubricate each part before seating the next injector may cause premature wear or tool damage. Also, make sure the forcing bolt turns freely and does not have any damaged threads.

Illustration 8. Put A Small Amount Of Thread Lubricant On Wear Button.10. Install the forcing bridge with three 7X-0457 Bolts (5) and three 9M-1974 Hard Washers (6). Put the two long legs of the forcing bridge in the two rocker arm shaft support holes closest to the injector. The short leg of the forcing bridge sits on the intake manifold bolt boss.

Illustration 9. Install Forcing Bridge.11. Tighten forcing bridge mounting bolts (5) to 28 7 N m, 2.9 0.7 meter kg, (21 5 lb. ft.).

Damage to the head could occur if bridge mounting bolts (5) are not tightened to the specified torque.

Illustration 10. Tighten Forcing Bridge Bolts.12. Tighten the forcing bolt finger tight.13. Use a 9U-5019 Torque Wrench and tighten the forcing bolts to 34 1.4 N m, 3.5

Have questions with 101901-4291?

Group cross 101901-4291 ZEXEL

Isuzu

Isuzu

101901-4291

9 400 616 238

1156017020

INJECTION-PUMP ASSEMBLY

8PC1

8PC1