Information injection-pump assembly

ZEXEL

101901-0630

1019010630

ISUZU

1156006960

1156006960

Rating:

Cross reference number

ZEXEL

101901-0630

1019010630

ISUZU

1156006960

1156006960

Zexel num

Bosch num

Firm num

Name

101901-0630

1156006960 ISUZU

INJECTION-PUMP ASSEMBLY

10PA1 * K

10PA1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

R: right hand row, L: left hand row 1L-8R-7L -6R-5L-4 R-3L-10R

R: right hand row, L: left hand row 1L-8R-7L -6R-5L-4 R-3L-10R

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Opposite to the driving side NO.1

Opposite to the driving side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.5 27.5

Cal 1-8 deg. 27 26.5 27.5

Difference between angles 2

Cal 1-7 deg. 72 71.5 72.5

Cal 1-7 deg. 72 71.5 72.5

Difference between angles 3

Cal 1-6 deg. 99 98.5 99.5

Cal 1-6 deg. 99 98.5 99.5

Difference between angles 4

Cal 1-5 deg. 144 143.5 144.5

Cal 1-5 deg. 144 143.5 144.5

Difference between angles 5

Cal 1-4 deg. 171 170.5 171.5

Cal 1-4 deg. 171 170.5 171.5

Difference between angles 6

Cal 1-3 deg. 216 215.5 216.5

Cal 1-3 deg. 216 215.5 216.5

Difference between angles 7

Cal 1-10 deg. 243 242.5 243.5

Cal 1-10 deg. 243 242.5 243.5

Difference between angles 8

Cal 1-9 deg. 288 287.5 288.5

Cal 1-9 deg. 288 287.5 288.5

Difference between angles 9

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

84.6

82.6

86.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.3

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

86

84

88

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.3

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

77

76

78

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

11.7+-0.

5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

72

69

75

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Injection quantity adjustment_05

Adjusting point

E

Rack position

8.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

8

9.3

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

14.7+-0.

5

Pump speed

r/min

150

150

150

Each cylinder's injection qty

mm3/st.

95

95

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

1050

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

1.1

0.1

1.1

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

2.8

2.3

3.3

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

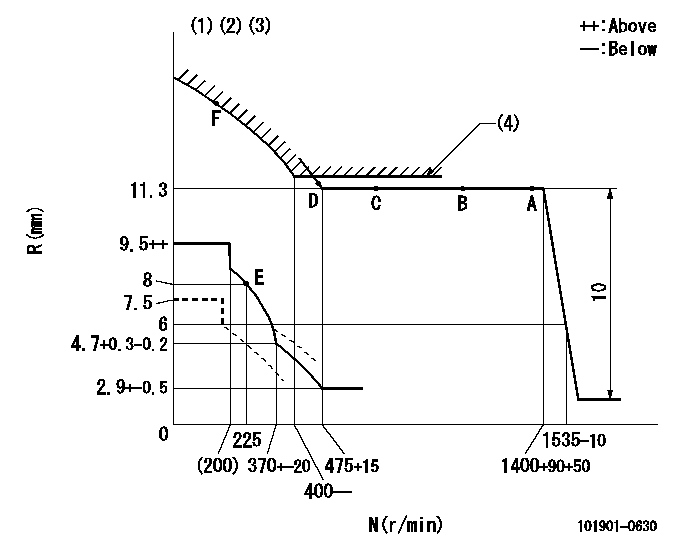

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Rack limit (operating at delivery)

(3)Set the load lever's stop position so that R = aa (N = 0).

(4)Excess fuel setting for starting: SXL

----------

DL=6-0.5mm aa=7.5mm SXL=12+0.2mm

----------

----------

DL=6-0.5mm aa=7.5mm SXL=12+0.2mm

----------

0000000901

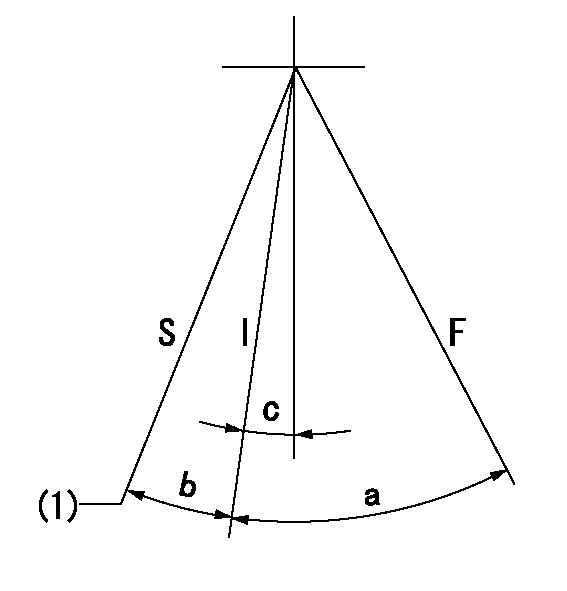

F:Full load

I:Idle

S:Stop

(1)Rack position aa (pump speed bb r/min )

----------

aa=7.5mm bb=0r/min

----------

a=30.5deg+-3deg b=13deg+-5deg c=1.5deg+-5deg

----------

aa=7.5mm bb=0r/min

----------

a=30.5deg+-3deg b=13deg+-5deg c=1.5deg+-5deg

Information:

Removal Procedure

Illustration 4 g06465824When Diesel Exhaust Fluid (DEF) lines from the DEF injectors are removed for service, there is a possibility of small DEF quantity to be spilled over the DEF injector body.DEF forms a white, crystalline residue when allowed to dry. This reside can prevent proper sealing of the fittings when the hose is reinstalled. Refer to Illustration 4.DEF Hose Removal Procedure

After the engine is shut off, ensure that the purge cycle is completed before performing the procedure.

Illustration 5 g06465825

Push the hose fitting toward the tube to relieve the force on the hose fitting. Refer to Illustration 5.

Illustration 6 g06465826

Press and hold down the retainer clip button and pull the hose fitting off tube. Refer to Illustration 6.

Illustration 7 g06465828

If hose fitting fails to release, place a compressed air nozzle up against gaps "A" and "B" and blow out dirt and debris for a few seconds on each gap Refer to Illustration 7. Then repeat steps 2 and 3.DEF Hose Cleaning Procedure

Illustration 8 g06465829

DEF and other debris will interfere with the fitting functionality and will prevent sealing of the connector interface. Refer to Illustration 8.

Illustration 9 g06465830

Soak the hose end in distilled water for about a minute. Refer to Illustration 9.

Illustration 10 g06465831

Gently shake the hose dry. Refer to Illustration 10.

Do not use wipes or cloth to wipe the connector. This could introduce fibers into the DEF system and cause DEF pump or DEF injector error codes.DEF Hose Inspection Procedure

Illustration 11 g06465835

Push the end of the retainer clip (D1). Refer to Illustration 11.

Illustration 12 g06465838

Release the force on the clip (D2) to ensure that the clip travels freely. Refer to Illustration 12.

If clip does not travel freely, repeat the DEF hose cleaning procedure.

If clip does not travel freely after two or more cleaning attempts, the clip is damaged and the hose has to be replaced.Installation Procedure of DEF Hose Assembly

Illustration 13 g06465839

Rinse the DEF injector body with distilled water with the electrical connector connected to the injector. Refer to Illustration 13.

Illustration 14 g06465841

Insert the hose into the injector fitting until the retainer clip snaps into place and the tube comes to a stop. Refer to Illustration 14.

Illustration 15 g06465842

Hold the molded portion of the hose and pull away from the injector to ensure it is fully seated and locked in place. Refer to Illustration 15.

If hose does not lock in place and pulls out, the hose end connection or clip has been damaged. Replace the DEF line.

Illustration 4 g06465824When Diesel Exhaust Fluid (DEF) lines from the DEF injectors are removed for service, there is a possibility of small DEF quantity to be spilled over the DEF injector body.DEF forms a white, crystalline residue when allowed to dry. This reside can prevent proper sealing of the fittings when the hose is reinstalled. Refer to Illustration 4.DEF Hose Removal Procedure

After the engine is shut off, ensure that the purge cycle is completed before performing the procedure.

Illustration 5 g06465825

Push the hose fitting toward the tube to relieve the force on the hose fitting. Refer to Illustration 5.

Illustration 6 g06465826

Press and hold down the retainer clip button and pull the hose fitting off tube. Refer to Illustration 6.

Illustration 7 g06465828

If hose fitting fails to release, place a compressed air nozzle up against gaps "A" and "B" and blow out dirt and debris for a few seconds on each gap Refer to Illustration 7. Then repeat steps 2 and 3.DEF Hose Cleaning Procedure

Illustration 8 g06465829

DEF and other debris will interfere with the fitting functionality and will prevent sealing of the connector interface. Refer to Illustration 8.

Illustration 9 g06465830

Soak the hose end in distilled water for about a minute. Refer to Illustration 9.

Illustration 10 g06465831

Gently shake the hose dry. Refer to Illustration 10.

Do not use wipes or cloth to wipe the connector. This could introduce fibers into the DEF system and cause DEF pump or DEF injector error codes.DEF Hose Inspection Procedure

Illustration 11 g06465835

Push the end of the retainer clip (D1). Refer to Illustration 11.

Illustration 12 g06465838

Release the force on the clip (D2) to ensure that the clip travels freely. Refer to Illustration 12.

If clip does not travel freely, repeat the DEF hose cleaning procedure.

If clip does not travel freely after two or more cleaning attempts, the clip is damaged and the hose has to be replaced.Installation Procedure of DEF Hose Assembly

Illustration 13 g06465839

Rinse the DEF injector body with distilled water with the electrical connector connected to the injector. Refer to Illustration 13.

Illustration 14 g06465841

Insert the hose into the injector fitting until the retainer clip snaps into place and the tube comes to a stop. Refer to Illustration 14.

Illustration 15 g06465842

Hold the molded portion of the hose and pull away from the injector to ensure it is fully seated and locked in place. Refer to Illustration 15.

If hose does not lock in place and pulls out, the hose end connection or clip has been damaged. Replace the DEF line.

Have questions with 101901-0630?

Group cross 101901-0630 ZEXEL

Isuzu

101901-0630

1156006960

INJECTION-PUMP ASSEMBLY

10PA1

10PA1